Self-circulation lubricating method and device of vertical gear reducer with forward-reverse alternative rotation function

A technology of positive and negative alternating rotation and reducer, which is applied to transmission parts, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of large power loss, complex structure, and increased rotation resistance of the reducer, and achieve Simple structure and appearance, reduced volume and weight, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

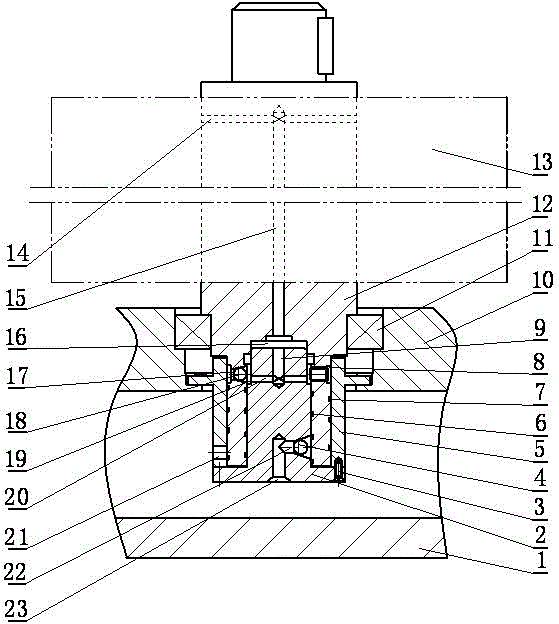

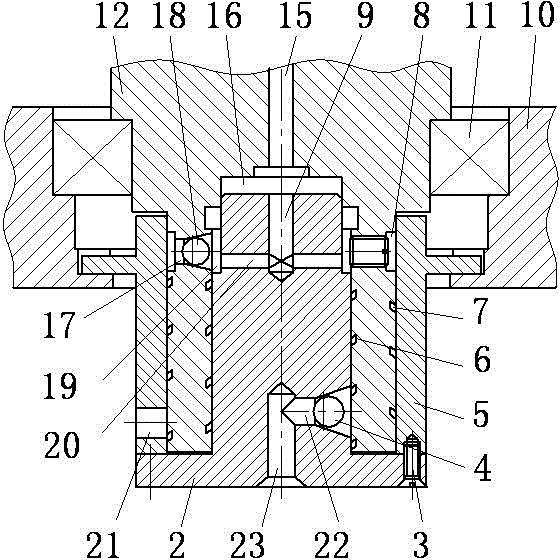

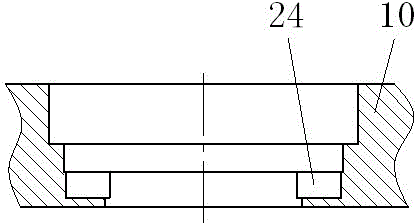

[0026] During specific implementation, the bearing seat 10 is fixed on the bottom of the box body 1 , and the bearing 11 on the input shaft 12 cooperates with the hole on the bearing seat 10 .

[0027] A plurality of outer helical grooves 7 are processed on the outer circle of the lower end of the input shaft 12, and a plurality of inner helical grooves 6 are processed in the hole. The rotation directions of the outer helical grooves 7 and the inner helical grooves 6 are opposite. When the input shaft 12 rotates clockwise, the outer helical groove 7 works to pump oil; when the input shaft 12 rotates counterclockwise, the inner helical groove 6 works to pump oil; when the outer helical groove 7 is left-handed, When the internal helical groove 6 is right-handed, the working pump oil direction is just opposite.

[0028] In the present invention, the pump core 2 and the pump sleeve 5 are connected as a whole by the screw 3, and cooperate with the outer circle and the hole wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com