A transmission lubricating cooling system

A lubricating cooling and transmission technology, applied in gear lubrication/cooling, elements with teeth, belts/chains/gears, etc., can solve the problems of reduced transmission life, high oil leakage risk, and large oil loss, etc., to achieve lubrication Cost reduction, simple oil pipe layout, and small oil loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

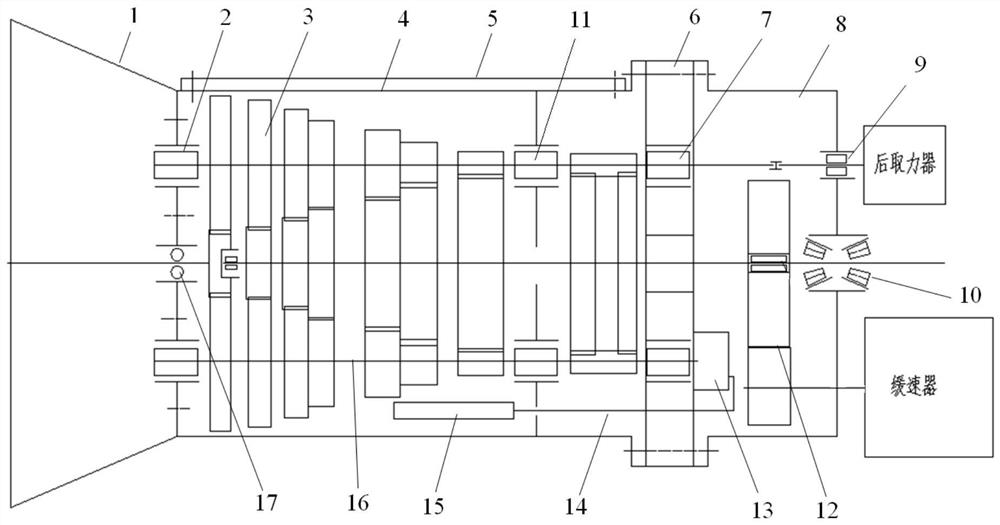

[0032] For the three-countershaft overdrive transmission, the present invention provides a transmission lubricating and cooling system. The system adopts oil pump pressure lubrication, and realizes the lubrication of each upper lubrication point of the three-countershaft transmission through the combination of the casing oil channel and the oil pipe. At the same time, the oil A strong cooling interface is reserved at the beginning of the road, and an external forced cooling system can be connected to control the transmission oil temperature within a reasonable range, prolonging the service life of the oil product and the transmission.

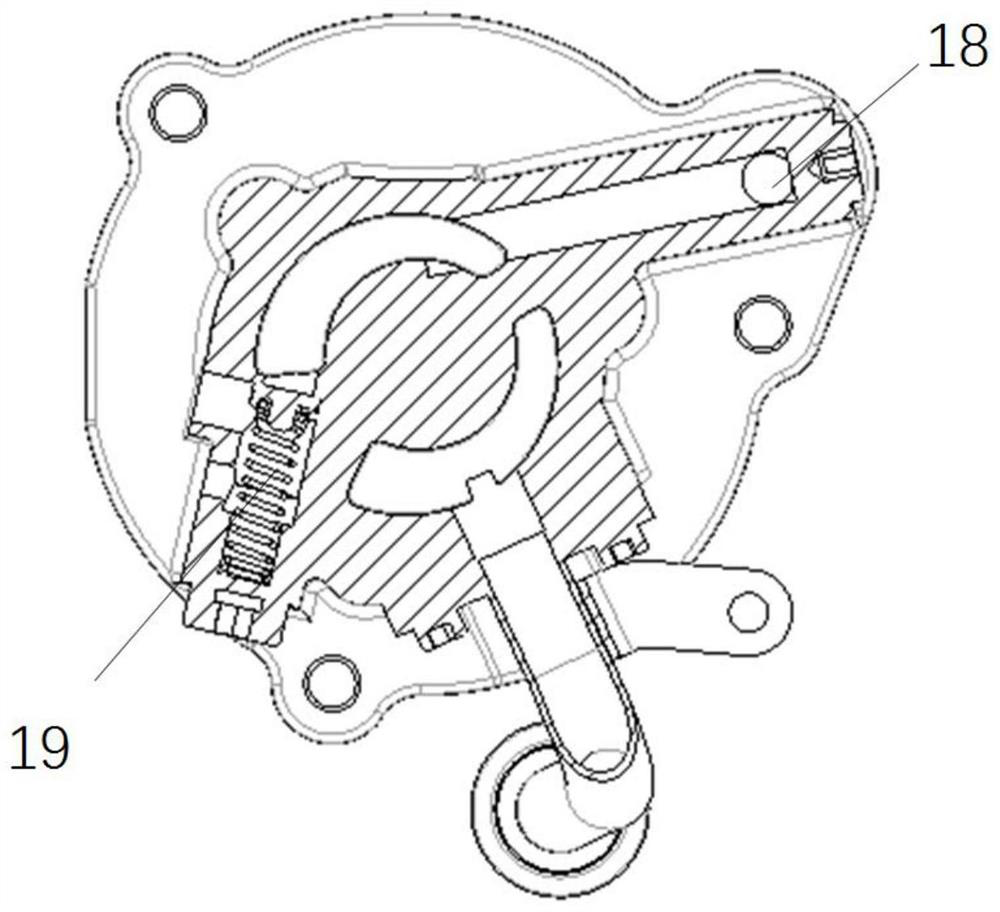

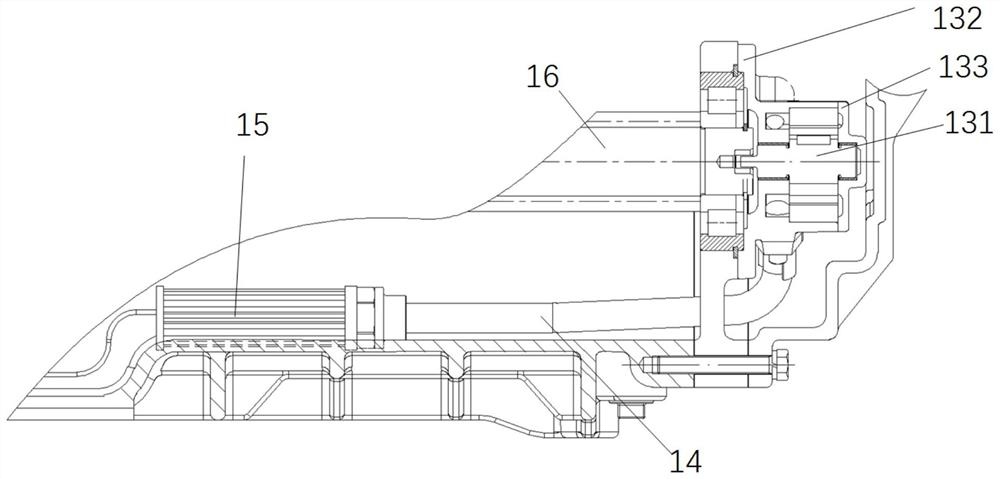

[0033] Such as figure 1As shown, the three-countershaft overdrive transmission of the present invention is an 8-speed single-box three-countershaft overdrive transmission, comprising fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com