A new type of ball mill equipment

A ball mill, a new type of technology, is applied in the direction of mechanical equipment, engine components, engine lubrication, etc., and can solve problems such as lack of lubrication function, increased maintenance costs, and scrapped bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

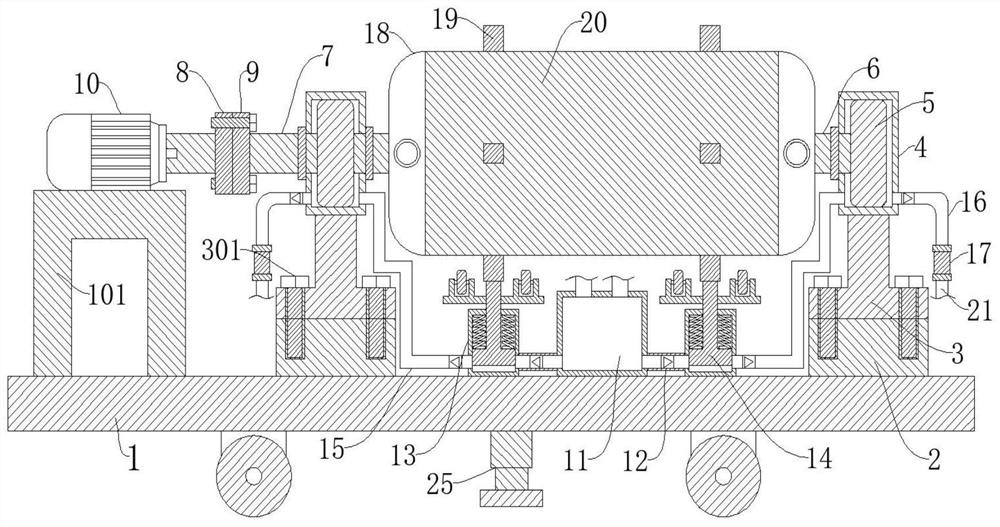

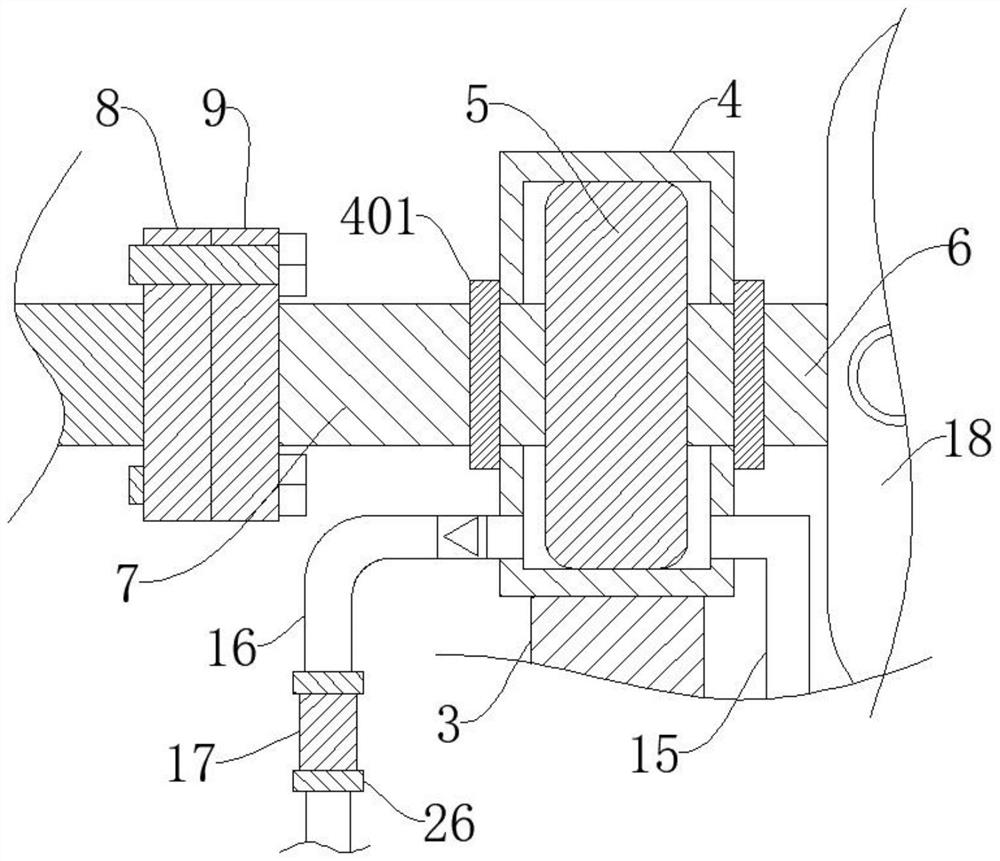

[0028] refer to Figure 1-5 , a new type of ball mill equipment, including a base 1, a cylinder 18, a base 2 is connected to both sides of the upper end of the base 1, a support base 3 is detachably connected to the base 2 through a first bolt 301, and the upper end of the support base 3 is fixedly connected to a The bearing box 4 is connected with a rotating bearing 5 in rotation in the bearing box 4, and the end of the rotating bearing 5 close to the cylinder body 18 is fixedly connected with the first rotating shaft 6, and the ends of the two first rotating shafts 6 away from the rotating bearing 5 are respectively connected to the cylinder body The two ends of 18 are fixedly connected, and the outer side of any one of the rotating bearings 5 is fixedly connected with the second rotating shaft 7, and one end of the base 1 close to the second rotating shaft 7 is connected with a receiving frame 101, and the receiving frame 101 is fixedly connected with a first rotating shaf...

Embodiment 2

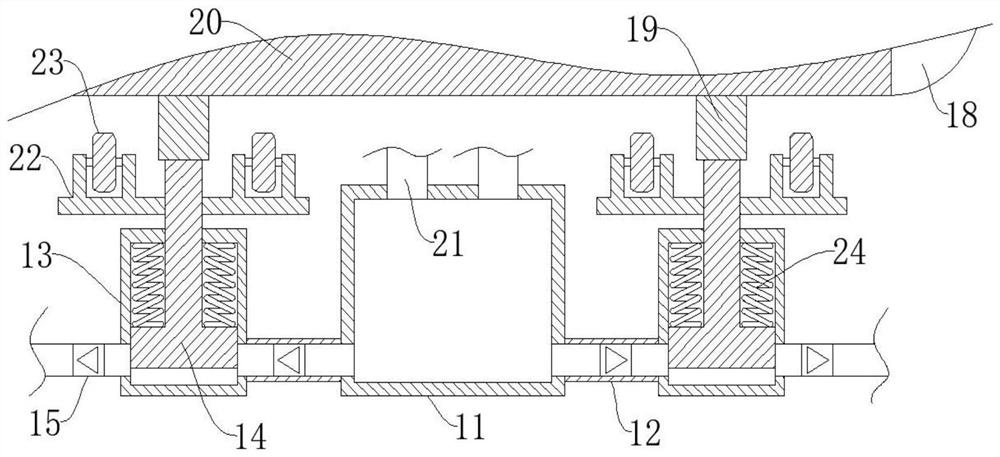

[0031] refer to Figure 1-3 , a new type of ball mill equipment, which is basically the same as that of Embodiment 1, furthermore: a support frame 22 is fixedly connected to both sides of the upper end of the piston 14, and a knocking wheel 23 is connected to the support frame 22 through rotation of a rotating shaft, and the surface of the cylinder body 18 is coated with There is a sound-absorbing paint 20, and through the setting of the knocking wheel 23, the fines attached to the inner wall of the cylinder 18 can be effectively knocked off to make it fall off, preventing incomplete unloading and part of the material attached to the cylinder On the inner wall of 18, the practicability of the device is effectively improved. Through the setting of the sound-absorbing paint 20, the knocking wheel 23 can be effectively silenced, and at the same time, the interior of the cylinder 18 can be sound-insulated, providing a comfortable environment for the staff. working environment.

Embodiment 3

[0033] refer to Figure 1-5 , a new type of ball mill equipment, basically the same as embodiment 1, further is: the number of each group of semi-circular arc blocks 19 is 4, and the beating speed of the beating wheel 23 is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com