Lubricating oil, lubricating oil additive and preparation method therefor

A technology for lubricating oil additives and lubricating oils, applied in the direction of additives, lubricating compositions, petroleum industry, etc., to achieve the effects of mild reaction conditions, easy operation, and simple synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

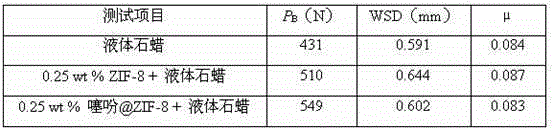

[0017] Preparation method of ZIF-8 material filled with sulfur-containing thiophene: 100 mg of activated ZIF-8 material (BanerjeeR, PhanA, WangB, KnoblerC, FurukawaH, O'KeeffeM, et al. High-throughput synthesis of zeoliticimidazolateframeworksandapplicationtoCO 2 capture.Science[J].2008,319(5865):939-43.) soaked in 10mL thiophene (C 4 h 4 S, Sigma-Aldrich (Shanghai) Trading Co., Ltd.) solution, placed in a polytetrafluoroethylene reactor, placed in an oven at 100±20°C for 7 days, after the reaction was completed, the obtained product was used in a centrifuge Hydroethanol (CH 3 CH 2 OH, Aladdin Reagent (Shanghai) Co., Ltd.) to neutrality, and after drying at room temperature, the thiophene ZIF-8 material was obtained.

[0018] The original sample ZIF-8 material is directly added to the base lubricating oil liquid paraffin as a lubricating additive. Lubricating oil samples with wt% ZIF-8 material.

[0019] The prepared thiophene ZIF-8 material is directly added to the base ...

Embodiment 2

[0028] The preparation method of chlorobenzene ZIF-8 material is the same as embodiment 1, difference is: the reagent containing chlorine element that present embodiment adopts: 10mL chlorobenzene (C 6 h 5 Cl, Aladdin Reagent (Shanghai) Co., Ltd.).

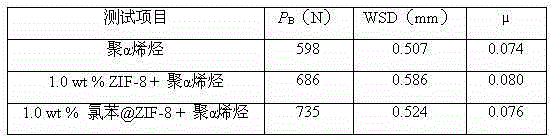

[0029] The lubricating oil sample containing 1.0wt% ZIF-8 material is the same as in Example 1, except that the base lubricating oil is polyalphaolefin.

[0030] The prepared chlorobenzene ZIF-8 material is directly added to the base lubricating oil polyalphaolefin as a lubricating additive, the addition amount is 1.0wt% of the total amount, and placed in a KQ218 ultrasonic oscillator for 60 minutes to obtain a uniformly dispersed Lubricant oil sample with 1.0wt% chlorobenzene ZIF-8 material.

[0031] Using the four-ball friction and wear testing machine to evaluate the maximum non-jamming load ( P B ) and anti-friction and anti-wear properties, the method is the same as in Example 1. The measured data are shown in Table 2. ...

Embodiment 3

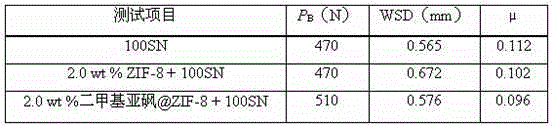

[0037] The preparation method of dimethyl sulfoxide ZIF-8 material is the same as embodiment 1, the difference is: 10mL thiophene is replaced by 10mL dimethyl sulfoxide (C 2 h 6 OS, Aladdin Reagent (Shanghai) Co., Ltd.).

[0038] The lubricating oil sample containing 2.0wt% ZIF-8 material is the same as in Example 1, except that the base lubricating oil liquid paraffin is replaced by mineral oil 100SN.

[0039] Add the prepared dimethyl sulfoxide ZIF-8 material directly into the base lubricating oil polyalphaolefin as a lubricating additive, the addition amount is 2.0wt% of the total amount, and place it in a KQ218 ultrasonic oscillator for 60 minutes to obtain a dispersed Homogeneous lubricant oil sample containing 2.0 wt% DMSO ZIF-8 material.

[0040] Using the four-ball friction and wear testing machine to evaluate the maximum non-jamming load (P B ) and anti-friction and anti-wear properties, the method is the same as in Example 1. The measured data are shown in Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com