Preparation method and electro-catalysis application of chiral nickel-based metal organic framework material

A metal-organic framework and organic framework technology, applied in the field of electrocatalysis, can solve the problems of unclear application advantages of chiral metal-organic framework materials, and achieve the effects of large-scale production, good reproducibility, and reduced catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 8.9mg of thiazolidine-2,4-dicarboxylic acid in a 10mL glass vial, add 4mL of deionized water, disperse the mixture evenly by ultrasonic to obtain a clear solution, accurately pipette pyridine (100μL) and mix evenly, then add nitric acid hexahydrate Nickel 29.1 mg, a homogeneous clear solution was obtained by ultrasonication. The airtight glass vial was placed in an oven at 140°C for 72 hours, and then cooled to room temperature naturally. The product was a black precipitate, and no crystalline material was formed, so XRD detection could not be performed.

Embodiment 2

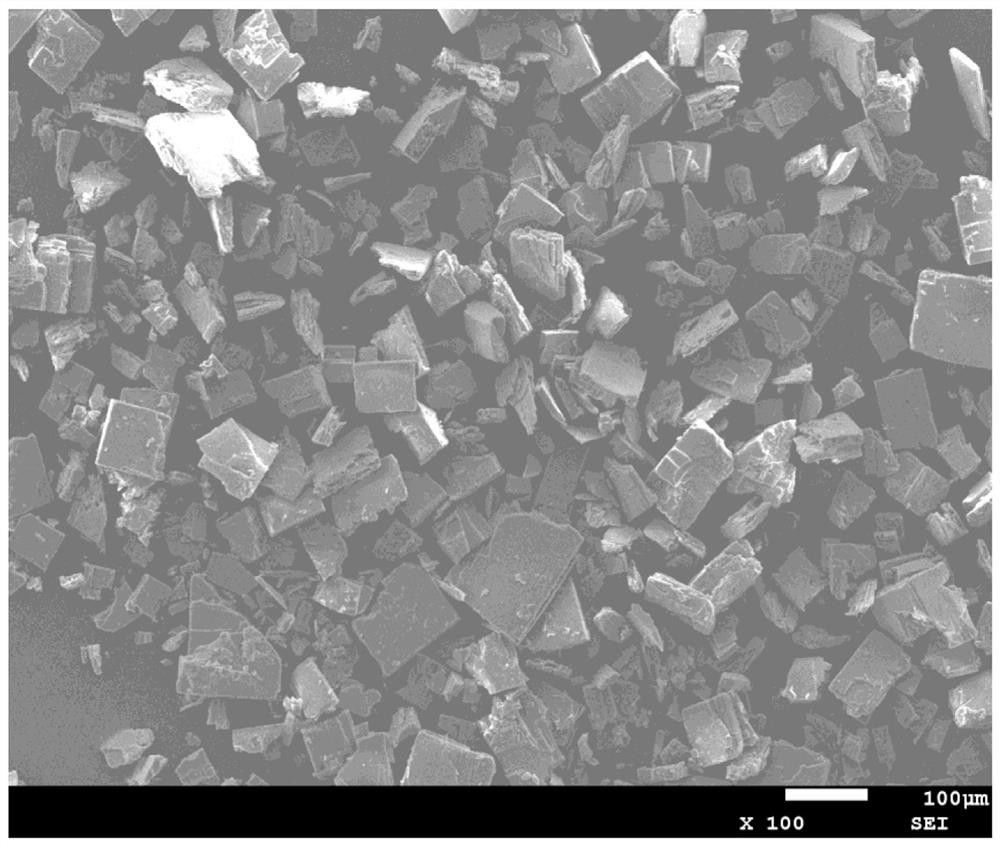

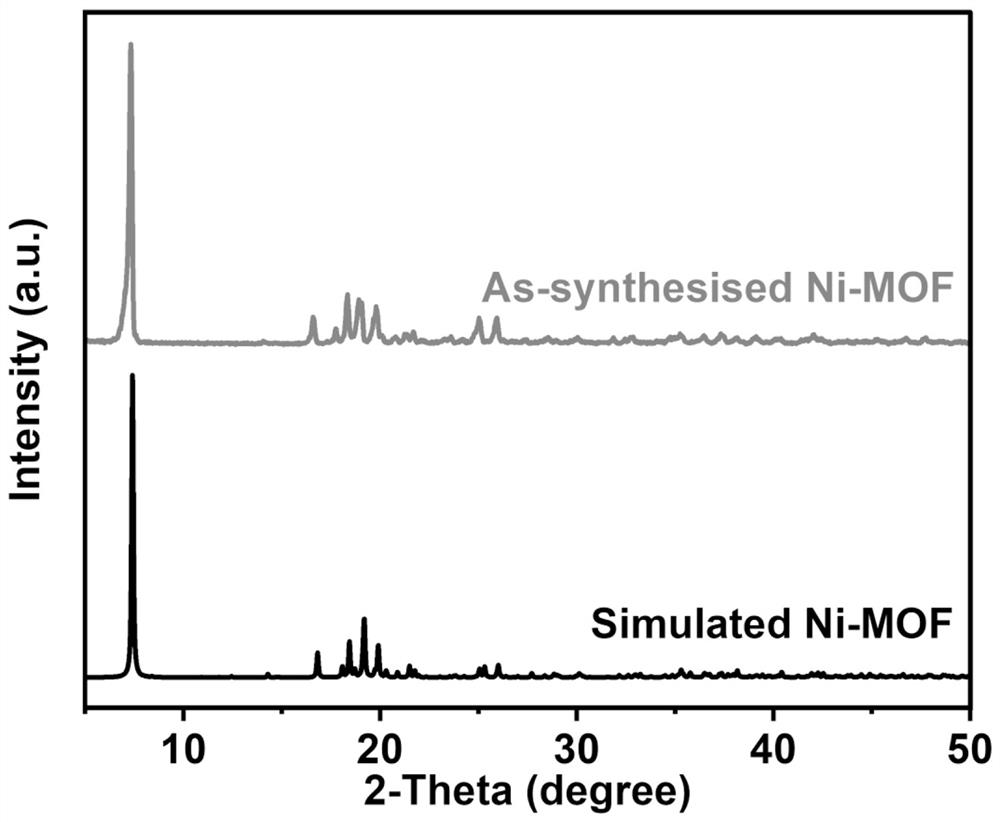

[0032] Take 8.9mg of thiazolidine-2,4-dicarboxylic acid in a 10mL glass vial, add 4mL of deionized water, disperse the mixture evenly by ultrasonic to obtain a clear solution, accurately pipette pyridine (100μL) and mix evenly, then add nitric acid hexahydrate Nickel 29.1 mg, a homogeneous clear solution was obtained by ultrasonication. The airtight glass vial was placed in an oven at 120°C for 72 hours, and then naturally cooled to room temperature to obtain a blue transparent bulk crystalline material (Ni-MOF), with a product yield of 65% (based on the raw material thiazolidine-2, 4-Dicarboxylic acid used for mass calculation).

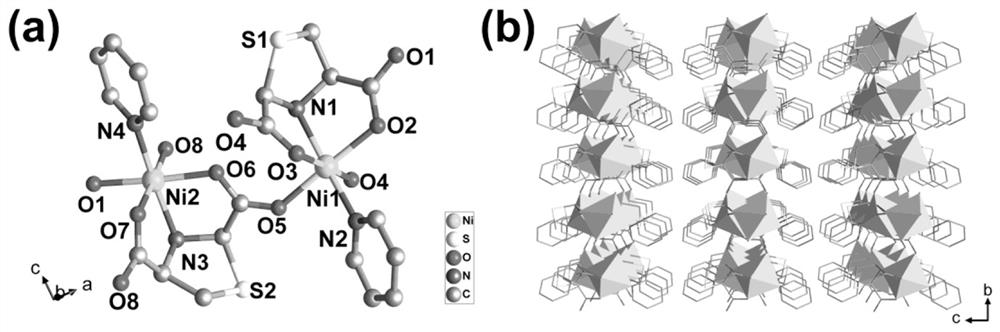

[0033] figure 1 The coordination environment diagram (a) and three-dimensional packing diagram (b) of the obtained Ni-MOF are shown. Such as the coordination environment diagram ( figure 1 (a)), the smallest asymmetric unit of each Ni-MOF consists of two Ni 2+ , two TDAs, and two PYs. Among them, each Ni 2+ Coordinate with four O from two TDA ...

Embodiment 3

[0038] Take 8.9mg of thiazolidine-2,4-dicarboxylic acid in a 10mL glass vial, add 4mL of deionized water, disperse the mixture evenly by ultrasonic to obtain a clear solution, accurately pipette pyridine (100μL) and mix evenly, then add nitric acid hexahydrate Nickel 29.1 mg, a homogeneous clear solution was obtained by ultrasonication. The airtight glass vial was placed in an oven at 100°C for 72 hours, and then naturally cooled to room temperature to obtain a blue transparent bulk crystalline material with a product yield of 41% (based on the raw material thiazolidine-2,4-dicarboxylic acid mass calculations used).

[0039] The shape and size of the Ni-MOF sample prepared by this ratio and condition are uniform, but the yield of the obtained crystalline material is lower than that of Example 2. It has been detected that the structure of the Ni-MOF is the same as that of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com