High-glossiness coating, high-glossiness paper and preparation method thereof

A coating and high-gloss technology, used in paper coatings, coatings, papermaking, etc., can solve the problems of high-gloss paint waste, failure to achieve, and uneven gloss of high-gloss paper, and achieve the effect of reducing the coating amount and simplifying the synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

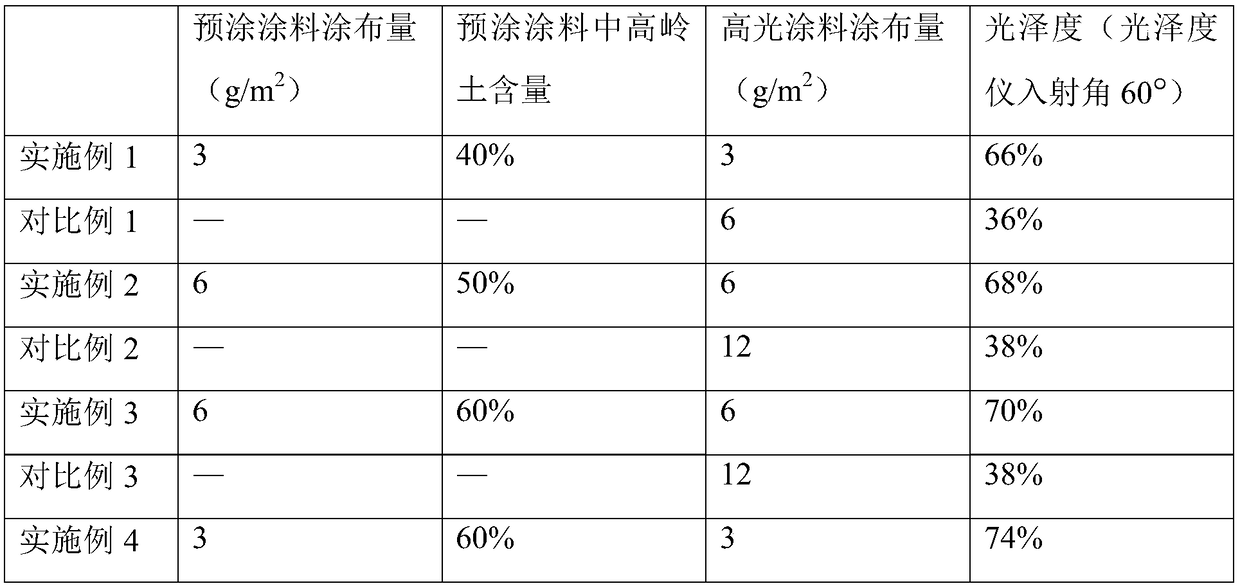

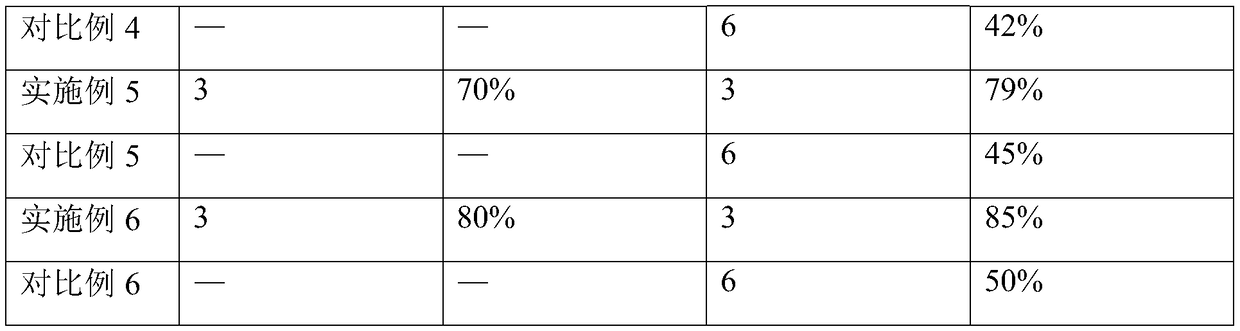

Examples

Embodiment 1

[0037] This embodiment provides a high-gloss paper and its preparation method, the preparation steps are as follows:

[0038] (1) Papermaking

[0039] Get 100g of dry coniferous wood pulp board and soak, defrost, beating to 17 ° SR, add 0.5g polyamide polyamine-epichlorohydrin resin (PAE), 0.01g nanocellulose, 0.5g carboxylate to the obtained raw pulp Methyl cellulose, 0.2g cationic starch, 1.0g light calcium carbonate, stir and mix to obtain mixed pulp; take mixed pulp by 0.6g dry pulp and carry out papermaking (quantitative 30g / m 2 ).

[0040] (2) Sizing

[0041] Carry out surface sizing to the paper that step (1) obtains with styrene-butadiene latex, and the surface sizing amount is 2g / m 2 , Calendering treatment after drying, the calendering line pressure is 45kN / m.

[0042] (3) Preparation of pre-coating paint and high-gloss paint

[0043] Pre-coating paint (mass percentage): 40% of kaolin, 5% of nanocellulose + polyvinyl alcohol, 2% of polyoxyethylene polyoxypropyle...

Embodiment 2

[0050] This embodiment provides a high-gloss paper and its preparation method, the preparation steps are as follows:

[0051] (1) Papermaking

[0052] Take 100g of dry broad-leaved wood pulp board and soak, thaw, and beat to 17 ° SR, add 0.5g melamine formaldehyde resin, 0.01g nanocellulose, 0.5g carboxymethyl cellulose, 0.2g cationic starch to the obtained raw pulp , 1.0g light calcium carbonate, stir and mix to obtain mixed pulp; take mixed pulp by 0.6g dry pulp and carry out papermaking (quantitative 30g / m 2 ).

[0053] (2) Sizing treatment

[0054] Carry out surface sizing to the paper that step (1) obtains with styrene-butadiene latex, and the surface sizing amount is 2g / m 2 , Calendering treatment after drying, the calendering line pressure is 45kN / m.

[0055] (3) Preparation of pre-coating paint and high-gloss paint

[0056] Pre-coating paint (mass percentage): 50% of kaolin, 10% of nanocellulose + polyvinyl alcohol, 2% of polyoxyethylene polyoxypropylene block cop...

Embodiment 3

[0063] This embodiment provides a high-gloss paper and its preparation method, the preparation steps are as follows:

[0064] (1) Papermaking

[0065] Take 50g of dry coniferous wood pulp board and 50g of dry hardwood pulp board and carry out mixed soaking, thawing, and beating to 17°SR, and add 0.5g of urea-formaldehyde resin, 0.01g of nanocellulose, and 0.5g of carboxymethyl to the obtained raw pulp Base cellulose, 0.2g cationic starch, 1.0g light calcium carbonate, stir and mix to obtain mixed pulp; take mixed pulp by 0.6g dry pulp and carry out papermaking (quantitative 30g / m 2 ).

[0066] (2) Sizing treatment

[0067] Carry out surface sizing to the paper that step (1) obtains with styrene-butadiene latex, and the surface sizing amount is 2g / m 2 , Calendering treatment after drying, the calendering line pressure is 45kN / m.

[0068] (3) Preparation of pre-coating paint and high-gloss paint

[0069] Pre-coating paint (mass percentage): 60% of kaolin, 5% of nanocellulos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com