Nano-graphite concentrate liquid composition and lubricating oil prepared by using composition

A technology of nano-graphite and composition, which is applied in lubricating compositions, petroleum industry, additives, etc. It can solve the problems of large specific surface area of nano-materials, difficulty in uniform dispersion of nano-graphite, and poor oil solubility of nano-graphite, achieving excellent dispersion, Improved gasoline mileage and durability, excellent anti-wear and anti-friction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

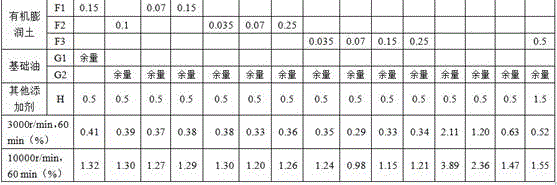

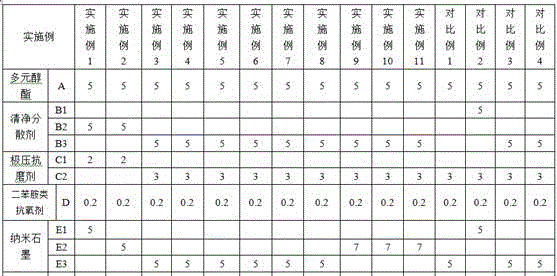

[0130] See Table 1 for the contents of each component of the nano-graphite concentrated liquid composition and the results of the sedimentation test in the examples.

[0131] Wherein the preparation method of the nano-graphite concentrated liquid composition is as follows:

[0132] (1) Add the detergent dispersant, organic bentonite, and nano-graphite to the base oil in sequence according to the weight parts described in Table 1, and perform ultrasonic homogenization or high-power ultrasonic dispersion to obtain mixed oil A;

[0133] (2) Add the polyol ester, extreme pressure antiwear agent and diphenylamine antioxidant to the above mixed oil A in sequence, stir until mixed evenly, and obtain the nanographite concentrate liquid composition.

[0134]Example 6 and Example 9 of the nano-graphite concentrated liquid composition, comparative examples 1 to 4 were added to the G2 base oil at a weight ratio of 5% and 10%, respectively, and stirred and mixed uniformly to obtain a nano-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com