Ultra-low-viscosity energy-saving gasoline engine oil and preparation method thereof

A gasoline engine oil, ultra-low viscosity technology, used in the field of lubricants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

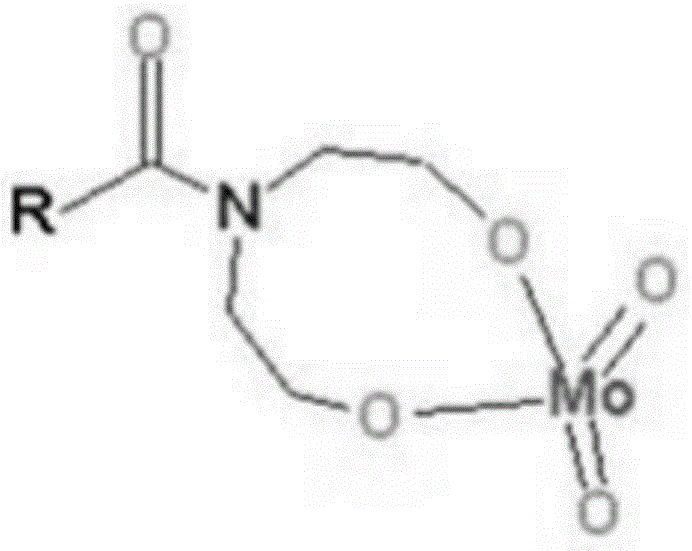

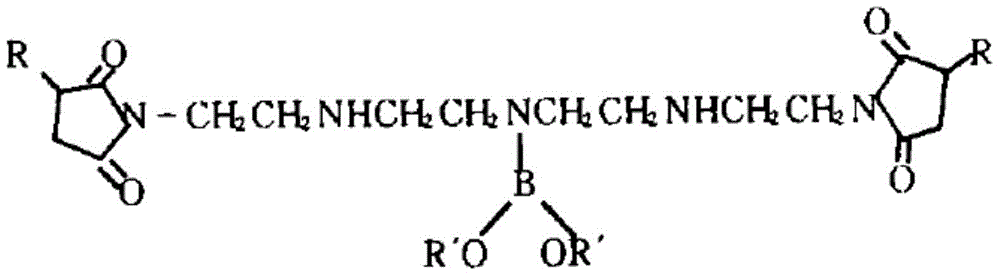

[0061] Preparation of steam engine oil compounding agent: Add 3kg of calcium alkylbenzene sulfonate and 1kg of calcium sulfide alkylphenate to 60kg of alkyl dibenzyltoluene and stir at 400 rpm for 10min, then add 6kg of borated polyisobutylene succinimide Rotate at a speed of 400 rpm and stir for 20 minutes to obtain the compound agent for gasoline and engine oil.

[0062] The synthetic base oil is prepared by uniformly mixing 37.7 kg of polyalphaolefin, 33 kg of dioctyl adipate, 10 kg of pentaerythritol tetramyristate, and 5.297 kg of 13-docosyl-13-docosyl ester.

[0063] Ultra-low viscosity energy-saving gasoline engine oil raw materials: 10kg gasoline engine oil compounding agent, 0.3kg antioxidant, 1.5kg hydrogenated styrene-isoprene copolymer, 1.5kg ethylene-propylene copolymer, molybdenum diisooctyl dithiocarbamate 0.35kg, amino diisopropyl tungsten dithiophosphate 0.05kg, simethicone oil 0.003kg, synthetic base oil 85.997kg.

[0064] The antioxidant consists of 0.1kg2,...

Embodiment 2

[0067] The energy-saving gasoline engine oil of ultra-low viscosity is prepared by the method for embodiment 1, difference only is: described antioxidant is made of 0.15kg2,4-dimethyl-6-tert-butylphenol, 0.15kg2,2'-methylene Bis-(4-methyl-6-tert-butylphenol) composition. Obtain the ultra-low viscosity energy-saving gasoline engine oil of embodiment 2.

Embodiment 3

[0069] The ultra-low viscosity energy-saving gasoline engine oil was prepared according to the method of Example 1, the only difference being that the antioxidant was composed of 0.15kg 2,4-dimethyl-6-tert-butylphenol and 0.15kg dioctyl diphenylamine. Obtain the ultra-low viscosity energy-saving gasoline engine oil of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com