Energy-saving diesel engine oil with ultra-long oil change mileage and preparation method thereof

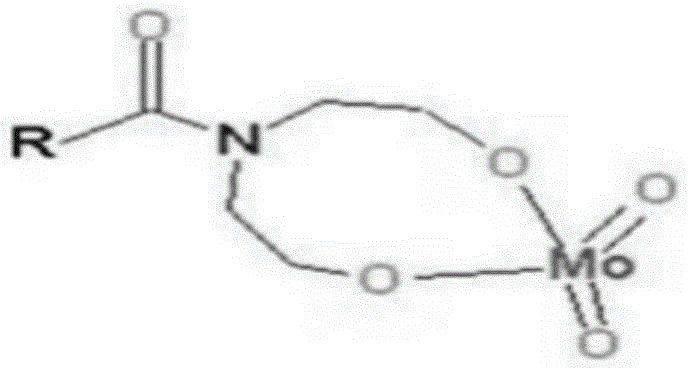

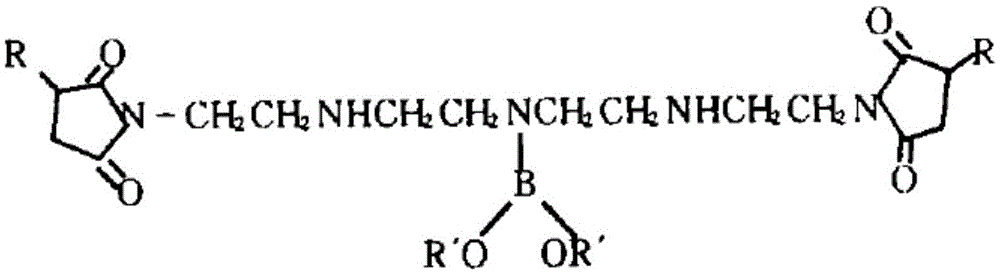

A technology of diesel engine and diesel oil, applied in the field of lubricating oil, can solve the problems of easy oxidation of sulfur and phosphorus anti-wear agent at high temperature, poor oil solubility of boron substances, and poor stability of oil varieties, so as to promote effective operation and improve oil reduction. Anti-wear effect, good solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Preparation of diesel engine oil compounding agent: Add 3 kg of calcium alkylbenzene sulfonate and 1 kg of sulfurized calcium alkylphenate to 60 kg of dioctyl adipate and stir at 400 rpm for 10 min, then add borated polyisobutylene succinimide 6 kg was stirred at 400 rpm for 20 minutes to obtain the diesel engine oil compounding agent.

[0055] Raw materials for energy-saving diesel engine oil with super long oil change intervals: diesel engine oil compounding agent 15kg, molybdenum diisooctyldithiocarbamate 0.5kg, antioxidant 1.2kg, hydrogenated styrene isoprene copolymer 2.5kg, ethylene propylene Copolymer 2.5kg, simethicone 0.003kg, synthetic base oil 77.97kg.

[0056] Described antioxidant is made of 0.4kg4,4'-methylene bis(2,6-di-tert-butylphenol), 0.4kg2,2'-methylene bis(4-ethyl-6-tert-butylphenol ), 0.4kg dioctyl diphenylamine composition.

[0057] The synthetic base oil is obtained by uniformly mixing 30kg of polyalphaolefin, 23kg of pentaerythritol tetramyris...

Embodiment 2

[0060] Prepare the energy-saving diesel engine oil with super long oil change mileage according to the method of Example 1, the only difference is that: the antioxidant consists of 0.6kg4,4'-methylenebis(2,6-di-tert-butylphenol), 0.6 kg2,2'-methylenebis(4-ethyl-6-tert-butylphenol) composition. Obtain the energy-saving diesel engine oil of the ultra-long oil change mileage of embodiment 2.

Embodiment 3

[0062] Prepare the energy-saving diesel engine oil with super long oil change mileage according to the method of Example 1, the only difference is that: the antioxidant consists of 0.6kg4,4'-methylenebis(2,6-di-tert-butylphenol), 0.6 kg dioctyl diphenylamine composition. Obtain the energy-saving diesel engine oil of the ultra-long oil change mileage of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com