Water-soluble grinding fluid

A grinding fluid, water-soluble technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as unfavorable market competition, increase production costs, etc., and achieve the effects of less environmental pollution, extended service life, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

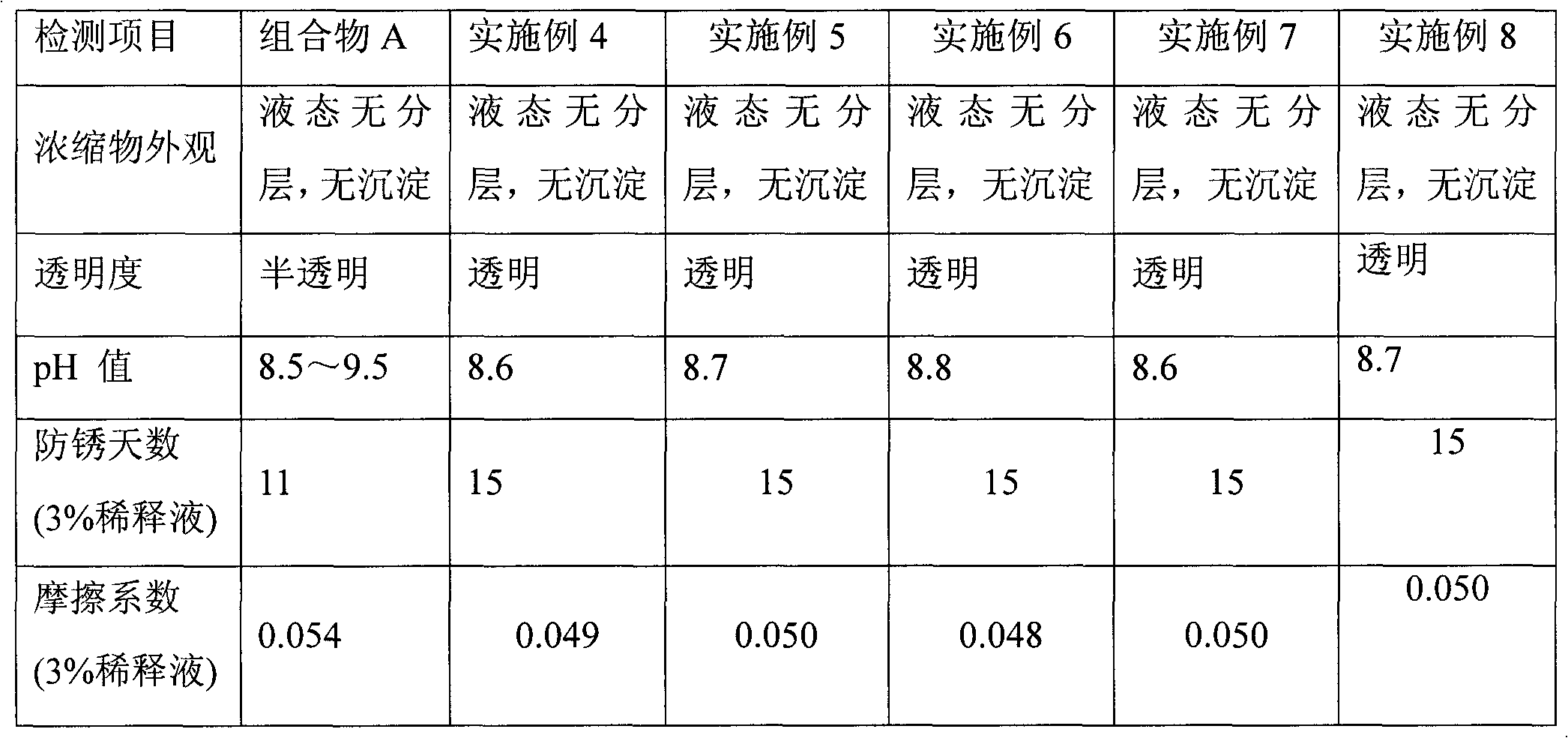

Examples

Embodiment 1

[0026] Put 150 grams of n-octanoic acid and 200 grams of monoethanolamine into a container at a temperature of 60-75° C. and stir for 1.5 hours until they are uniformly dissolved and a light yellow transparent liquid A is formed.

Embodiment 2

[0028] Add 200 grams of dodecenylsuccinic acid and 200 grams of triethanolamine into a container at a temperature of 60-80° C. and stir for 1.5 hours until they are uniformly dissolved and a transparent liquid B is formed.

Embodiment 3

[0030] Add 100 grams of dodecenylsuccinic acid half ester and 200 grams of triethanolamine into a container at a temperature of 60-80° C. and stir for 1.5 hours until they are uniformly dissolved and a transparent liquid C is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com