Method for preparing nanoscale lubricant additive

A lubricating oil additive, nano-scale technology, applied in the field of lubrication, can solve the problems of wide particle size distribution, difficult anion cleaning and removal, poor dispersion, etc., to achieve good dispersion, anti-rust performance, improved adaptability of sealing materials, anti-rust performance and the effect of improving the adaptability of sealing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

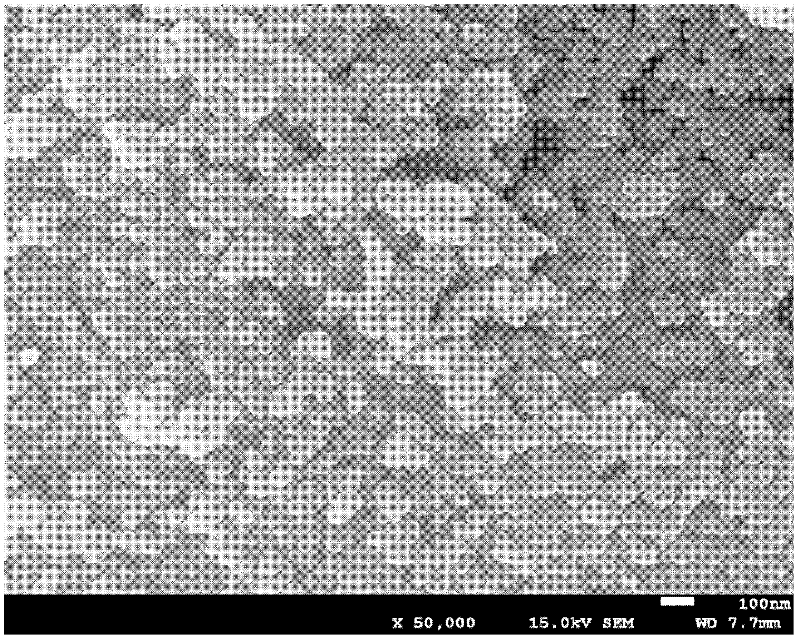

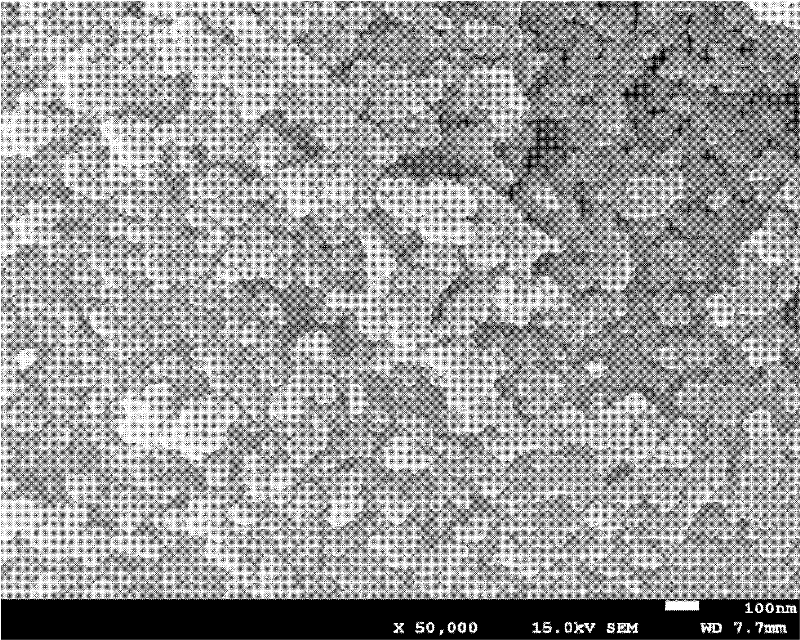

Image

Examples

Embodiment 1

[0029] A, solution preparation: accurately weigh borax (Na 2 B 4 o 10 10H 2 O) 19.08g, it was dissolved in 400mlH 2 In the mixed solvent of O and 100ml ethanol, obtain clear and transparent solution A; Take anhydrous calcium chloride 11.12g accurately with balance, it is dissolved in 80ml H 2 In the mixed solvent of O and 20ml ethanol, obtain clear and transparent solution B;

[0030] B. Ultrasonic reaction: under ultrasonic conditions at room temperature, pour transparent solution B into transparent solution A, add 1.00 g of surfactant CTAB, continue ultrasonication and stir for 10 minutes, and obtain white emulsion C; The frequency is 25kHz and the power is 1000w;

[0031] C. Product extraction:

[0032] C-1. Add 10ml of oleic acid and 10ml of petroleum ether with a boiling point between 60°C and 90°C into a small beaker, stir to mix the two evenly, and configure it as an extractant:

[0033] C-2. Add the prepared extractant to the white emulsion C, continue ultrasoni...

Embodiment 2

[0037] A, solution preparation: accurately weigh borax (Na 2 B 4 o 10 10H 2 O) 28.62g, it was dissolved in 600mlH 2 In the mixed solvent of O and 150ml ethanol, obtain clear and transparent solution A; Take anhydrous calcium chloride 11.12g accurately with balance, it is dissolved in 80ml H 2 In the mixed solvent of O and 20ml ethanol, obtain clear and transparent solution B;

[0038] B. Ultrasonic reaction: under ultrasonic conditions at room temperature, pour the transparent solution B into the transparent solution A, add 1.50 g of the surfactant CTAB, continue to sonicate and stir for 10 minutes to obtain a white emulsion C; during the ultrasonic treatment operation, the work of the ultrasonic instrument The frequency is 25kHz and the power is 1000w;

[0039] C. Product extraction:

[0040] C-1. Add 10ml of oleic acid and 10ml of petroleum ether with a boiling point between 60°C and 90°C into a small beaker, stir to mix the two evenly, and configure it as an extractan...

Embodiment 3

[0045] A, solution preparation: accurately weigh borax (Na 2 B 4 o 10 10H 2 O) 47.68g, it was dissolved in 1000mlH 2 In a mixed solvent of O and 250ml ethanol, a clear and transparent solution A is obtained; accurately weigh anhydrous calcium chloride 11.12g with a balance, and dissolve it in 80mlH 2 In the mixed solvent of O and 20ml ethanol, obtain clear and transparent solution B;

[0046] B. Ultrasonic reaction: under ultrasonic conditions at room temperature, pour the transparent solution B into the transparent solution A, add 2.00 g of the surfactant CTAB, continue to sonicate and stir for 10 minutes to obtain a white emulsion C; during the ultrasonic treatment operation, the work of the ultrasonic instrument The frequency is 25kHz and the power is 1000w;

[0047] C. Product extraction:

[0048] C-1. Add 10ml of oleic acid and 10ml of petroleum ether with a boiling point between 60°C and 90°C into a small beaker, stir to mix the two evenly, and configure it as an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com