Lubricating grease used for automobile hub bearing and preparation method thereof

A technology for automobile wheels and lubricating grease, which is applied in lubricating compositions and the petroleum industry, etc., can solve the problems of short service life of lubricating grease, and achieve the effects of long service life, scientific and reasonable formula, and good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix 80Kg of lauryl hydroxy fatty acid, 20Kg of stearic acid, and 400Kg of base oil, heat to 90°C and melt, add 8Kg of calcium hydroxide aqueous solution (calcium hydroxide 6.17Kg, water 1.83Kg) and 40Kg of lithium hydroxide aqueous solution (lithium hydroxide 28.3Kg, water 11.7Kg), saponification at 105°C for 2 hours, at 155°C, add 50Kg of sebacic acid, continue to react for two hours, after adding 450Kg of oil, raise the temperature to the highest temperature of 215°C, transfer to the blending tank, cool and reflux , at 150°C, 18MPa high-pressure homogenization, add 20Kg of sulfurized isobutylene, 10Kg of tricresyl phosphate, 40Kg of ethylene-propylene copolymer, and 12Kg of diphenylamine at below 100°C, mix well, test, and pack after passing the test.

Embodiment 2

[0035] Mix 70Kg of lauryl hydroxy fatty acid, 30Kg of stearic acid, and 450Kg of base oil, heat to 88°C to melt, add 14.5Kg of lithium hydroxide, saponify for 2 hours at 99-110°C, and add sebacic acid at 140°C 22Kg, add 9.3Kg of lithium hydroxide, react for two hours, continue to add 26.3Kg of azelaic acid, add 11.9Kg of lithium hydroxide, react for two hours, after adding 350Kg of residual oil, heat up to the highest temperature between 180 and 230°C, transfer To the blending kettle, cool and reflux, homogenize at 100-150°C, 15-25MPa high pressure, add borate 30Kg, molybdenum dibutyldithiocarbamate 10Kg, polyisobutylene 80Kg, phenyl α-naphthylamine below 100°C 12Kg, mixed evenly, inspected, and packaged after passing the test.

Embodiment 3

[0037] Mix 85Kg lauryl hydroxy fatty acid, 15Kg stearic acid, 35Kg sebacic acid, 10Kg boric acid, 540KG base oil, heat to 95°C and melt, add lithium hydroxide 33.5Kg, saponify at 108°C for 2 hours, and add more than 280KG After oiling, heat up to a maximum temperature of 220°C, transfer to a blending kettle, cool and reflux, homogenize at 120°C, 20MPa high pressure, add 15Kg of sulfurized isobutylene, 30Kg of sulfurized olefin cottonseed oil, 140Kg of polymethacrylate, 5Kg of diphenylamine and 8Kg of phenyl α-naphthylamine, mixed evenly, tested and packaged after passing the test.

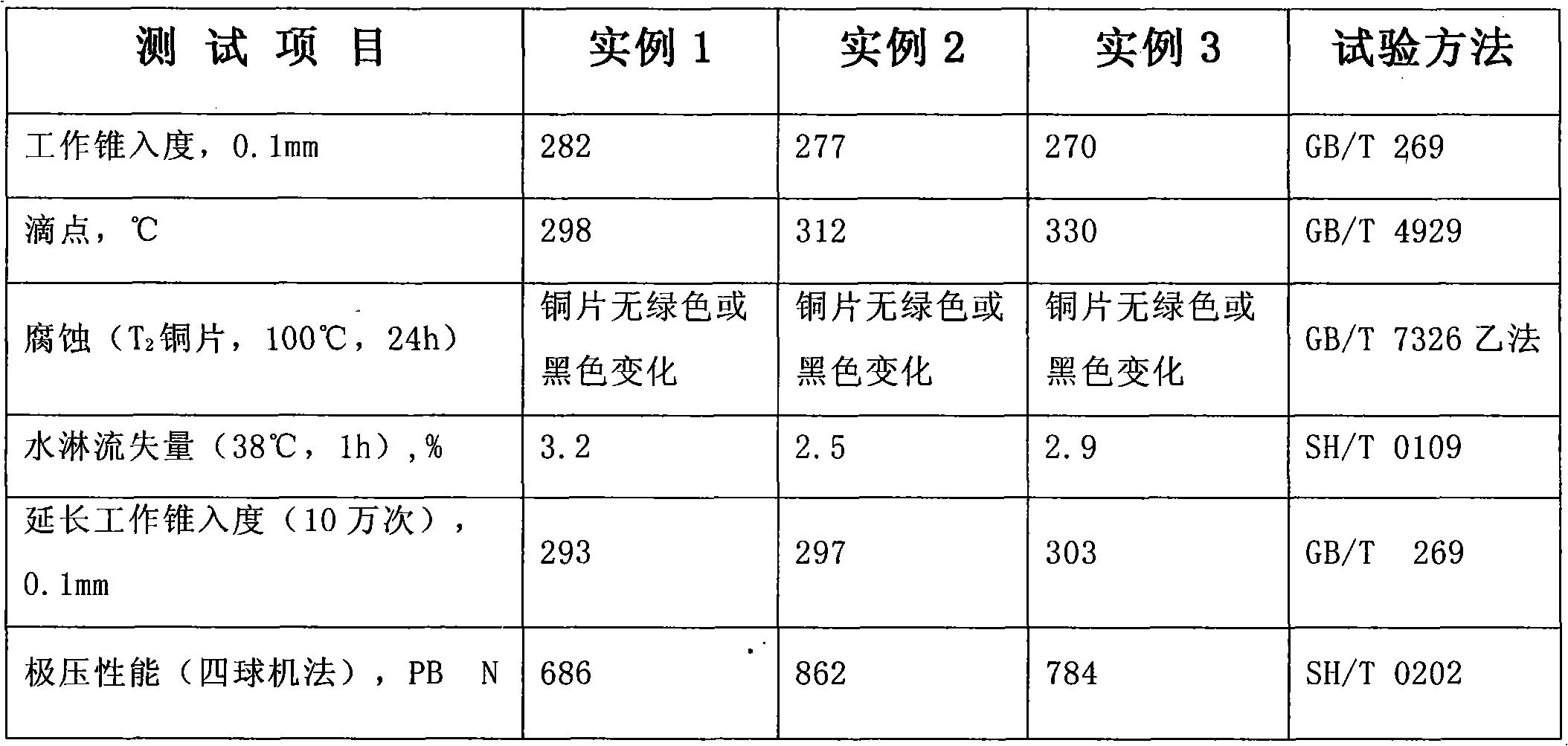

[0038] The present invention produces through three kinds of examples the automobile hub bearing lubricating grease, its physicochemical index is as follows:

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com