Antibacterial ES composite short fiber used for surface layer of hot-air non-woven fabric and preparation method of fiber

A technology of cloth surface layer and short fiber, which is applied in the field of antibacterial ES composite short fiber for air-through non-woven fabric surface layer and its preparation, which can solve the problem of poor softness of air-through non-woven fabric surface layer, long-lasting antibacterial effect, and insufficient transverse strength and other problems, to achieve good antibacterial effect, long-lasting antibacterial effect, and large lateral strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] An antibacterial ES composite short fiber for air-through non-woven fabric surface layer, the ES composite short fiber has a skin-core structure, that is, it is composed of a core layer and a skin layer; wherein, the core layer includes the following raw materials in parts by weight: polypropylene 90 ~97 parts, 2~5 parts of ethylene propylene copolymer; the skin layer includes the following raw materials in parts by weight: polyethylene 85~95 parts, methyl methacrylate graft modified polyethylene 5~7.5 parts, ethylene propylene copolymer 3-6 parts, 6-9 parts of composite antibacterial agent; the composite antibacterial agent includes the following raw materials in parts by weight: chitin grafted sodium polyacrylate superabsorbent resin and acrylic acid-2-acrylamide-2-methylpropanesulfonic acid 70-85 parts of copolymer, 25-37 parts of silver nitrate, 5-9 parts of nano-silver; the chitin-grafted sodium polyacrylate superabsorbent resin and acrylic acid-2-acrylamide-2-methy...

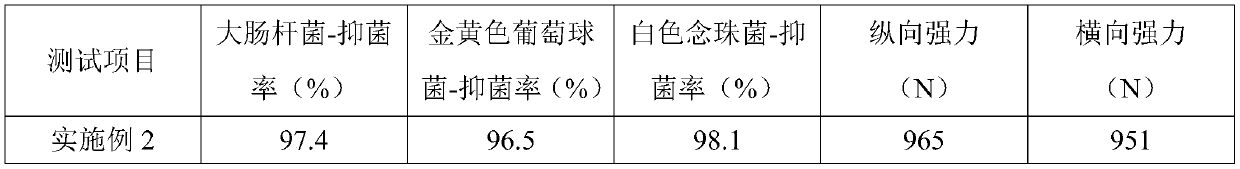

Embodiment 2

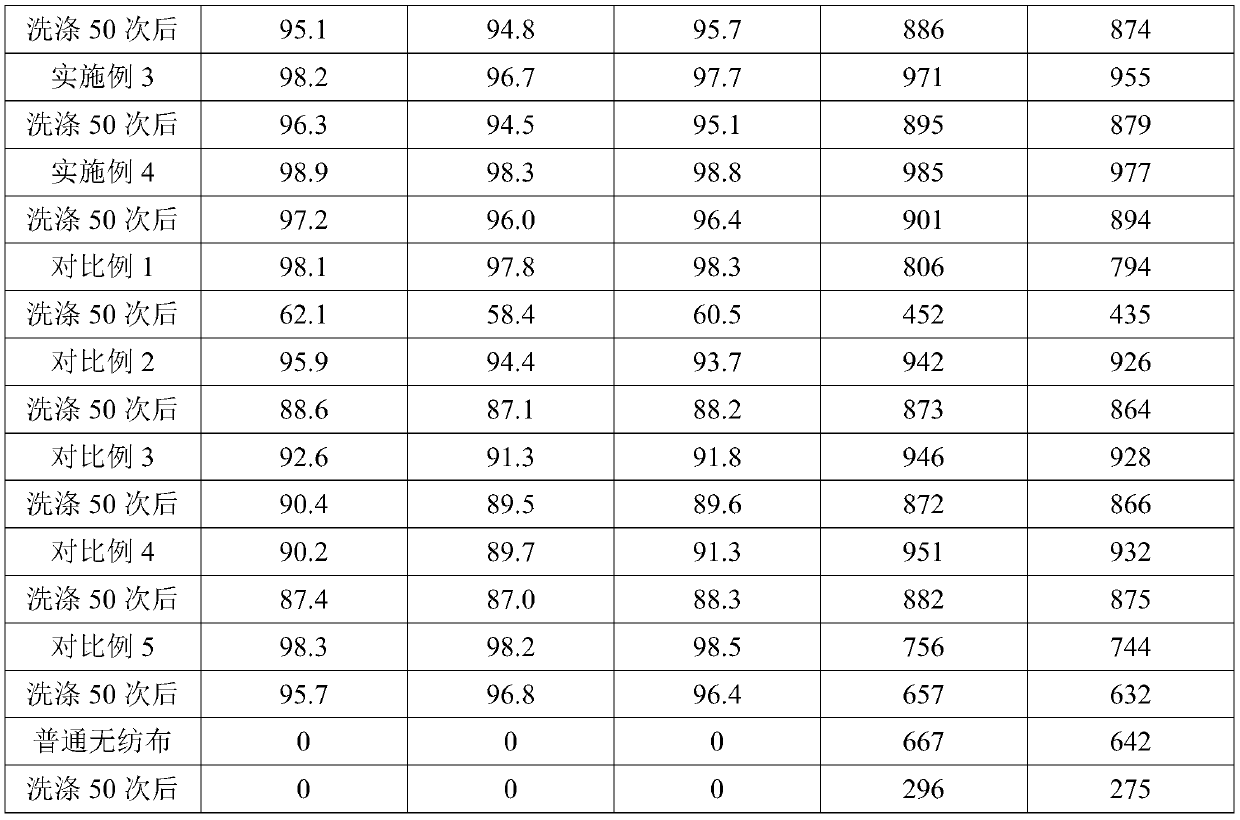

[0066] An antibacterial ES composite short fiber for air-through non-woven fabric surface layer, the ES composite short fiber has a skin-core structure, that is, it is composed of a core layer and a skin layer; wherein, the core layer includes the following raw materials in parts by weight: polypropylene 97 parts, 5 parts of ethylene-propylene copolymers; the cortex includes the following raw materials in parts by weight: 95 parts of polyethylene, 7.5 parts of methyl methacrylate graft modified polyethylene, 6 parts of ethylene-propylene copolymers, 9 parts of composite antibacterial agents ; The composite antibacterial agent includes the following raw materials by weight: chitin grafted sodium polyacrylate superabsorbent resin and 85 parts of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 37 parts of silver nitrate, nano silver 9 parts; the mass ratio of chitin-grafted sodium polyacrylate superabsorbent resin to acrylic acid-2-acrylamide-2-methylpropanesulfo...

Embodiment 3

[0081] An antibacterial ES composite short fiber for air-through non-woven fabric surface layer, the ES composite short fiber has a skin-core structure, that is, it is composed of a core layer and a skin layer; wherein, the core layer includes the following raw materials in parts by weight: polypropylene 92 parts, 3.5 parts of ethylene-propylene copolymers; the cortex includes the following raw materials in parts by weight: 87.5 parts of polyethylene, 6 parts of methyl methacrylate graft modified polyethylene, 4.4 parts of ethylene-propylene copolymers, 7.7 parts of composite antibacterial agents ; The composite antibacterial agent includes the following raw materials by weight: chitin grafted sodium polyacrylate superabsorbent resin and 75 parts of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer, 30 parts of silver nitrate, nano silver 7.4 parts; the mass ratio of the chitin-grafted sodium polyacrylate superabsorbent resin to the acrylic acid-2-acrylamide-2-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com