Antibacterial agent containing fluorinated alkyl quaternary ammonium salt, and preparation method and application of antibacterial agent

A technology of fluorine-containing alkyl group and fluorine-containing alkyl tertiary amine is applied in the field of antibacterial finishing application, preparation, and fluorine-containing alkyl quaternary ammonium salt silane. The effect of superior antibacterial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

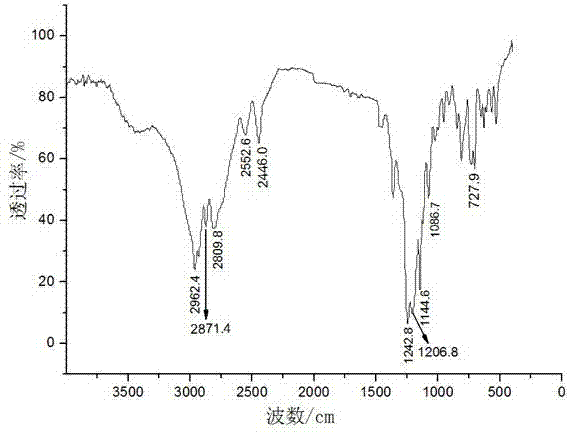

Image

Examples

Embodiment 1

[0036] 1, N -Trimethoxysilylpropyl- N, N -Synthesis of dimethyltridecafluorooctyl ammonium chloride

[0037] (1) N, N-Dimethyl-tridecafluorooctyl tertiary amine

[0038] Add 32.79g of 33% dimethylamine aqueous solution and 6.4g of sodium hydroxide into a three-necked flask equipped with magnetic stirring and a thermometer, add 34.16g of tridecafluorooctyl bromide dropwise after heating to 70°C, and continue the reaction after the dropwise addition 24h. After the reaction was completed, ethyl acetate was added to extract 50 mL x 3 times, the extracts were combined and washed with water 40 mL x 3 times. Add 3.5 g of anhydrous sodium sulfate to the oil phase and dry it for 12 hours, then filter off the desiccant sodium sulfate, and remove the extractant by rotary evaporation under reduced pressure to obtain 13.56 g of a light yellow transparent product.

[0039] (2) Quaternization

[0040] In a three-neck flask equipped with a magnetic stirrer and a thermometer N, N - 13.5...

Embodiment 2

[0058] 1, N -Trimethoxysilylpropyl- N, N -Synthesis of Diethyltridecafluorooctyl Ammonium Chloride

[0059] (1) N, N -Diethyl-tridecafluorooctyl tertiary amine

[0060] Add 17.55 g of diethylamine and 6.4 g of sodium hydroxide into a three-necked flask equipped with magnetic stirring and a thermometer. After heating to 70° C., add 34.16 g of tridecafluorooctylbromide dropwise, and continue the reaction for 24 hours after the addition is complete. After the reaction was completed, ethyl acetate was added to extract 50 mL x 3 times, the extracts were combined and washed with water 40 mL x 3 times. The oil phase was dried by adding 3.5 g of anhydrous sodium sulfate for 12 hours, the desiccant sodium sulfate was filtered off, and the filtrate was rotary evaporated under reduced pressure to remove the solvent to obtain 9.96 g of a light yellow transparent product.

[0061] (2) Quaternization

[0062] In a three-neck flask equipped with a magnetic stirrer and a thermometer N, ...

Embodiment 3

[0069] 1, N -Trimethoxysilylpropyl- N, N -Synthesis of Dibutyltridecafluorooctylammonium Bromide

[0070] (1) N, N -Dibutyl-tridecafluorooctyl tertiary amine

[0071] Add 12.38g of di-n-butylamine and 3.84g of sodium hydroxide into a three-necked flask equipped with magnetic stirring and a thermometer, heat the oil bath to 70°C, add 20.50g of tridecafluorooctyl bromide dropwise, and continue the reaction for 24 hours after the addition is complete . After the reaction, add 30 mL of ethyl acetate to extract x 3 times, combine the extracts, add deionized water to wash 20 mL x 3 times, add 2.0 g of anhydrous sodium sulfate to the oil phase and dry for 12 h, filter off the desiccant, and remove the filtrate by rotary evaporation under reduced pressure solvent to obtain 8.16 g of a light yellow transparent product.

[0072] (2) Quaternization

[0073] In a three-neck flask equipped with a magnetic stirrer and a thermometer N, N - 8.16 g of dibutyl-tridecafluorooctyl tertiary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com