Antibacterial polypropylene and a preparing method thereof

An antibacterial polypropylene and polypropylene resin technology, applied in the field of polymers, can solve the problems of poor antibacterial effect of antibacterial agents, restrictions on large-scale production and application, and complicated preparation process, so as to achieve improved rigidity, high activity, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

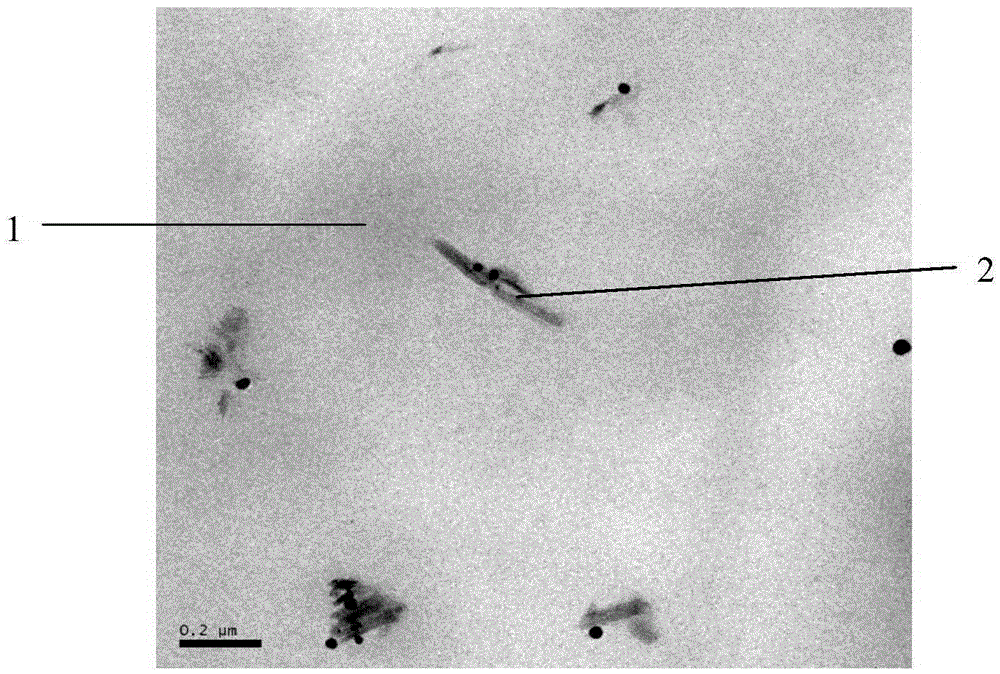

Embodiment 1

[0042] Take a certain amount of heat-activated and dispersed attapulgite (AT), prepare it into an aqueous suspension with a mass concentration of attapulgite of 5%, and then add silver nitrate solution (AgNO 3 / AT=17 / 100) was added to the attapulgite suspension, at 70°C, magnetically stirred for 2 hours, then the attapulgite suspension was spray-dried at 175°C, and the composite powder obtained by spray drying was collected. Finally, the obtained composite powder was calcined in a muffle furnace at 400° C. for 30 minutes to obtain attapulgite-nanometer silver composite inorganic powder.

Embodiment 2

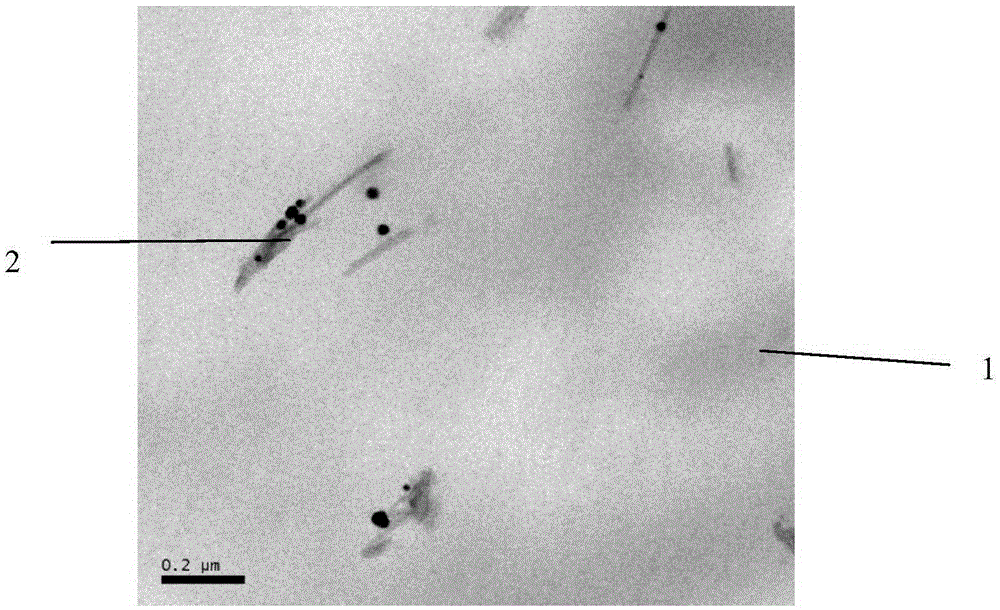

[0044] Except that the temperature of the magnetic stirring after mixing the silver nitrate solution and the attapulgite suspension was adjusted to 50° C., other process steps were the same as in Example 1.

Embodiment 3

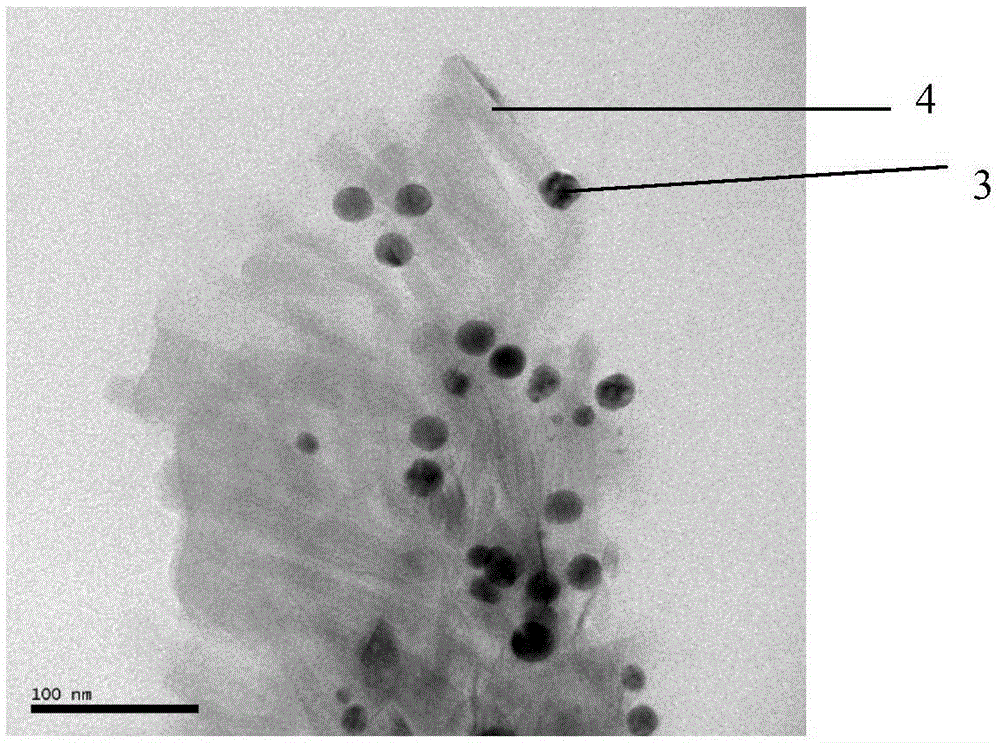

[0046] Weigh a certain amount of attapulgite (AT) that has been heat-activated and dispersed, and prepare an aqueous suspension with a mass concentration of attapulgite of 1%, and then add silver nitrate solution (AgNO 3 / AT=17 / 100) was added to the attapulgite suspension, stirred magnetically for 1 h at 50°C, and then the attapulgite suspension was spray-dried at 200°C, and the composite powder obtained by spray drying was collected. Finally, the obtained composite powder was calcined in a muffle furnace at 500° C. for 30 minutes to obtain attapulgite-nanometer silver composite inorganic powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com