Ginkgo biloba exocarp fermentation liquid as well as preparation method and application thereof

A technology of Ginkgo biloba testa and fermented liquid, applied in the direction of botany equipment and method, biochemical equipment and method, application, etc., can solve problems such as bad smell, pollution of surrounding waters, impact on surrounding environment, etc., and achieve easy industrialization Large-scale production, obvious economic benefits, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

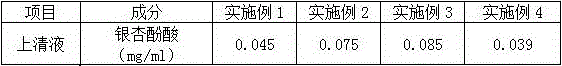

Examples

Embodiment 1

[0029] The culture medium of EM bacteria liquid is composed of the following components by mass percentage: 2% brown sugar, 1% edible urea, 0.1% vitamin K, 0.1% cysteine, 0.08% zinc, and the balance is water; the water in it is Prepared by boiling distilled water and cooling to 23-25°C.

[0030] The preparation process of the EM bacterial solution is as follows: inoculate the EM original dew into the above-mentioned medium with an inoculum amount of 5%, stir evenly, keep the temperature at 35°C-37°C for sealed culture, deflate once every 22-24 hours, when the pH value of the solution When it was 3.0, the fermentation was stopped, and the EM bacterial liquid that the number of viable bacteria was 8-12 billion / ml was prepared.

[0031] The preparation method of ginkgo testa fermented liquid adopts the following steps:

[0032] (1) Weigh 100kg of mature fresh ginkgo fruit, put it into a container, add 50L of EM bacteria liquid, stir evenly, keep the temperature at 30°C for 24 ho...

Embodiment 2

[0036] The culture medium of EM bacteria liquid is composed of the following components by mass percentage: 3% brown sugar, 0.5% edible urea, 0.12% vitamin K, 0.08% cysteine, 0.12% zinc, and the balance is water; The water is prepared by boiling distilled water and cooling to 23-25°C.

[0037] The preparation process of the EM bacterial liquid is as follows: Inoculate the EM original dew into the above-mentioned medium with an inoculum amount of 1%, stir evenly, keep the temperature at 35°C-37°C for sealed culture, deflate once every 22-24 hours, and when the solution When the pH value is 5.0, the fermentation is stopped, and the EM bacterial liquid with the number of viable bacteria of 8-12 billion / ml is prepared.

[0038] (1) Weigh 100kg of mature fresh ginkgo fruit, put it into a container, add 150L EM bacteria liquid, stir evenly, and keep the temperature at 40°C for 2 hours of fermentation;

[0039] (2) After the fermentation in step (1), remove the ginkgo fruit and coll...

Embodiment 3

[0042] The culture medium of EM bacteria liquid is composed of the following components by mass percentage: brown sugar 2.5%, edible urea 0.8%, vitamin K 0.12%, cysteine 0.08%, zinc 0.12%, and the balance is water; The water is prepared by boiling distilled water and cooling to 23-25°C.

[0043] The preparation process of the EM bacterial liquid is as follows: Inoculate the EM original dew into the above-mentioned medium with an inoculation amount of 3%, stir evenly, keep the temperature at 35°C-37°C for sealed culture, deflate once every 22-24 hours, and when the solution When the pH value is 4.0, the fermentation is stopped, and an EM bacterial liquid with a viable count of 100-120 / ml is prepared.

[0044] (1) Weigh 100kg of mature fresh ginkgo fruit, put it into a container, add 100L EM bacteria liquid, stir evenly, and keep the temperature at 35°C for 12 hours of fermentation;

[0045] (2) After the fermentation in step (1), remove the ginkgo fruit and collect the ferme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com