Preparation method of environment-friendly long-acting antibacterial polylactic acid material

An antibacterial polylactic acid and polylactic acid technology is applied in the field of degradable polymer composite materials, which can solve the problems of accelerated degradation rate and insufficient long-term effect, and achieve the effects of producing toxic side effects, high antibacterial efficiency, and no toxic side effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

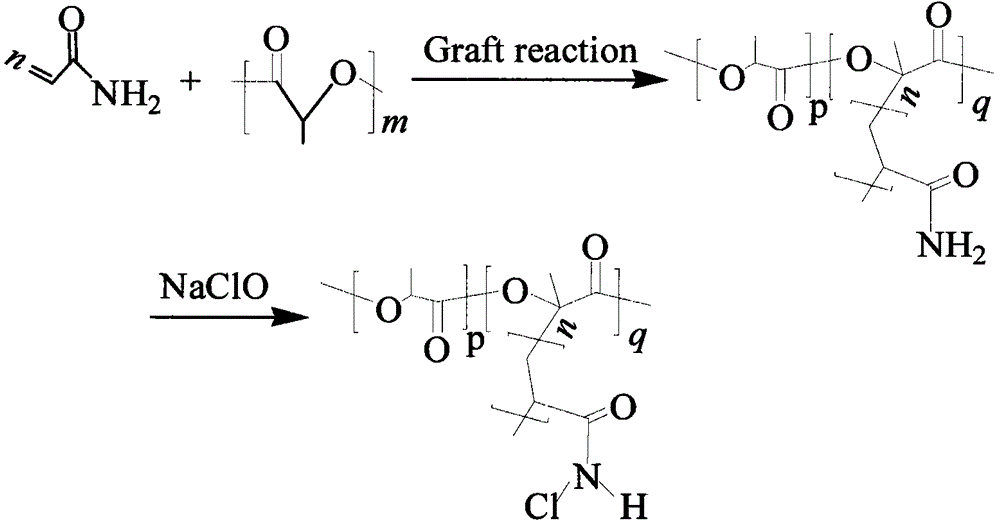

Embodiment 1

[0021] Dissolve 3.0g PLA in 40ml THF, stir to dissolve, add monomer acrylamide and initiator benzoyl peroxide (BPO) under the protection of nitrogen, continue nitrogen filling for 20min, immerse the reaction bottle in an oil bath, react for 1h, and react After completion, the polymer solution was slowly added dropwise to continuously stirring distilled water to obtain a white fibrous solid product, which was then washed with a large amount of deionized water and ether, and vacuum-dried to a constant weight to obtain a PLA-g-PAM copolymer. Y=(m 1 -m 0 ) / m 0 ×100% to calculate the grafting rate (m 0 is the dry weight of the sample before grafting; m 1 is the dry weight of the sample after grafting), and the grafting rate is 5.8%. Dissolve the copolymer in THF, drop it into a sodium hypochlorite solution with a mass fraction of 0.03%, adjust the pH to 7, and stir the reaction at room temperature for 20 minutes to obtain a halogenated amine compound. The product is washed repe...

Embodiment 2

[0023] Dissolve 3.0g PLA in 40ml THF, stir to dissolve, add monomer N-isopropylacrylamide and initiator BPO under nitrogen protection, continue nitrogen filling for 20min, then immerse the reaction bottle in oil bath, react for 1h, after the reaction is completed , the polymer solution was slowly added dropwise to continuously stirring distilled water to obtain a white fibrous solid product, which was then washed with a large amount of deionized water and ether, and vacuum-dried to a constant weight to obtain a PLA-g-PAM copolymer, by formula Y= (m 1 -m 0 ) / m 0 ×100% to calculate the grafting rate (m 0 is the dry weight of the sample before grafting; m 1 is the dry weight of the sample after grafting), and the grafting rate is 5.2%. Dissolve the copolymer in THF, drop it into a sodium hypochlorite solution with a mass fraction of 0.03%, adjust the pH to 7, and stir the reaction at room temperature for 20 minutes to obtain a halogenated amine compound. The product is washed...

Embodiment 3

[0025] Dissolve 3.0g PLA in 40ml THF, stir to dissolve, add monomer methacrylamide and initiator DCP under nitrogen protection, continue nitrogen filling for 20min, then immerse the reaction bottle in oil bath, react for 1h, after the reaction is completed, polymerize The product solution was slowly added dropwise to constantly stirring distilled water to obtain a white fibrous solid product, which was then washed with a large amount of deionized water and ether, and vacuum-dried to a constant weight to obtain a PLA-g-PAM copolymer. By formula Y=(m 1 -m 0 ) / m 0 ×100% to calculate the grafting rate (m 0 is the dry weight of the sample before grafting; m 1 is the dry weight of the sample after grafting), and the grafting rate is 4.3%. Dissolve the copolymer in THF, drop it into a sodium hypochlorite solution with a mass fraction of 0.03%, adjust the pH to 7, and stir the reaction at room temperature for 20 minutes to obtain a halogenated amine compound. The product is washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com