Heterophasic polypropylene with high impact properties

A technology of heterophasic polypropylene and propylene, applied in the field of manufacturing this polypropylene resin and manufacturing articles, can solve the problems of increased interfacial tension and increased size

Active Publication Date: 2010-11-24

ボレアリステクノロジーオイ

View PDF5 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

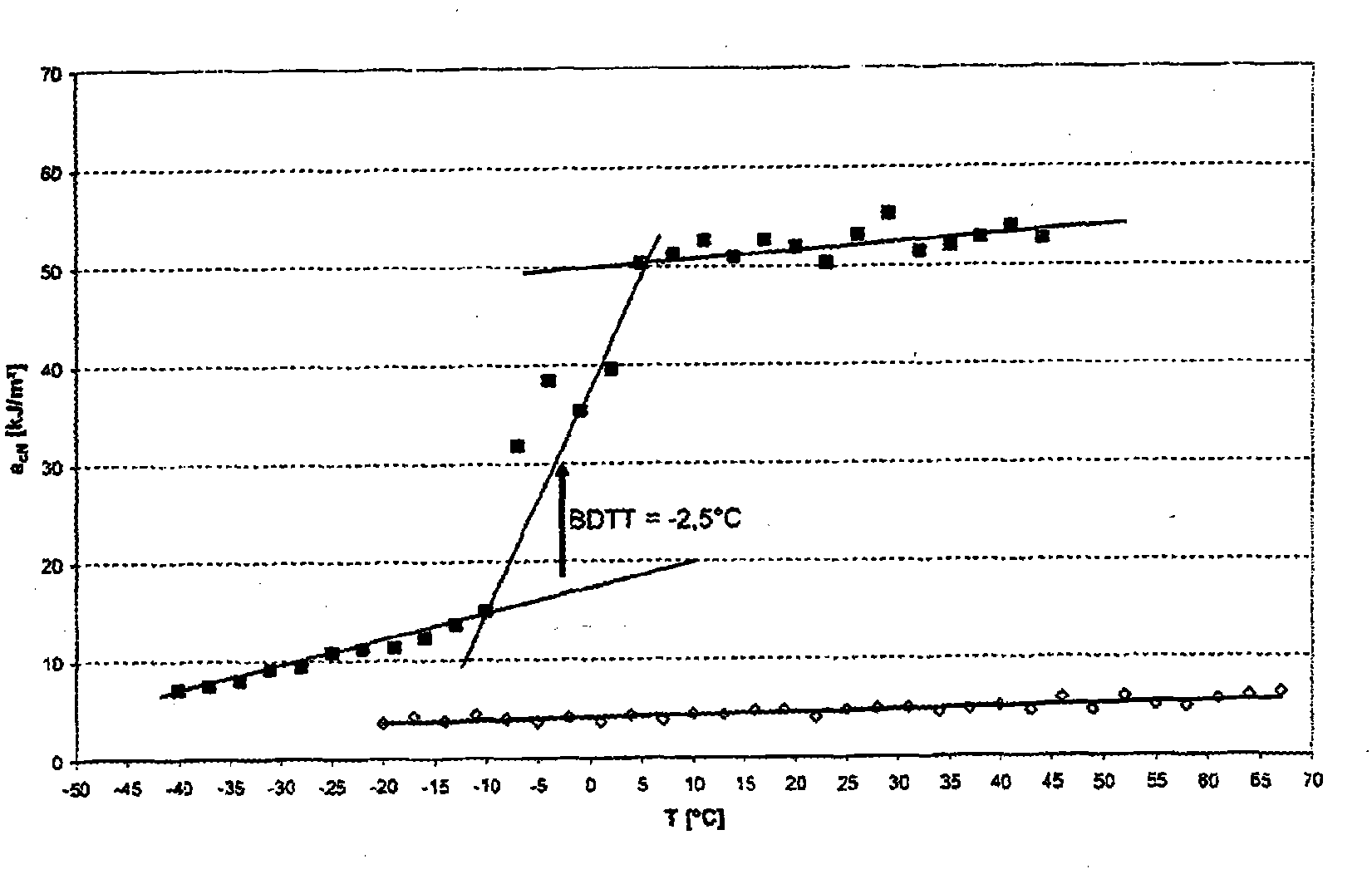

[0004] However, in Doshev, P. et al., Fracture characteristics and deformation behavior of heterophasic ethylene-propylenecopolymer as function of the dispersed phase composition (multiphase ethylene-propylene copolymer as the fracture characteristics and deformation behavior of the dispersed phase component function), Polymer( Polymer), 46(2005), 9411-9422, and Grein, C et al., Impact Modified Isotactic Polypropylene with Controlled Rubber Intrinsic Viscosities: Some New Aspects about Morphology and Fracture (impact modified isotactic polymer with controlled rubber intrinsic viscosity Stereopolypropylene: some new properties in morphology and fracture), J Appl Polymer Sci (Journal of Applied Polymer Chemistry), 87 (2003), 1702-1712, the authors of these documents have found that when using the traditional For four types of Ziegler-Natta catalysts, the increase of ethylene content in the dispersed phase of ethylene-propylene copolymer leads to an increase of interfacial tension

Consequently, the size of the ethylene-propylene copolymer particles increases, thereby negatively affecting the brittle-ductile transition and Charpy impact strength

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0167] 1. Method

[0168] a) Melt flow rate

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to a heterophasic polypropylene resin comprising a polypropylene homo- or copolymer matrix phase (A) and an ethylene-propylene copolymer phase (B) dispersed within the matrix, wherein the heterophasic polypropylene resin has a fraction insoluble in p-xylene (XCU) at 25 DEG C with an intrinsic viscosity of 2.0 dl / g or less, determined according to DIN EN ISO 1628-1 and -3, and a fraction soluble in p-xylene (XCS) at 25 DEG C having an intrinsic viscosity of 2.0 to 4.5 dl / g, determined according to DIN EN ISO 1628-1 and -3, and an amount of ethylene monomer units of 60 to 85 mol%, a heterophasic polypropylene composition comprising such a resin, a process for preparing that resin, and an article made thereof.

Description

technical field [0001] The present invention relates to a heterophasic polypropylene resin, which comprises a propylene homopolymer or copolymer matrix and an ethylene-propylene copolymer phase dispersed in the matrix, and has excellent impact resistance. In addition, the invention also relates to a method for the manufacture of such a polypropylene resin and the use of such a resin for the manufacture of articles. Background technique [0002] Known commercial polypropylenes are typically isotactic, semi-crystalline, thermoplastic polymer materials with an excellent cost performance ratio. However, their brittleness under impact loading at high speeds and especially at low temperatures limits their application as engineering thermoplastics. [0003] A known method of improving the toughness of isotactic polypropylene is to incorporate an ethylene-propylene copolymer as a dispersed phase into the polypropylene matrix. [0004] However, in Doshev, P. et al., Fracture charac...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F297/08C08F2/00C08L23/10

CPCC08L23/0815C08F297/08C08F297/083C08F210/16C08L2207/02C08L23/10C08F2/001C08L2666/06C08F210/06C08F2500/12C08F2500/15C08F2500/11C08F2500/17C08F2500/13

Inventor 斯韦恩·南塞斯佩塔尔·杜塞弗

Owner ボレアリステクノロジーオイ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com