Dry-type transformer with coil pressing structure

A technology of dry-type transformer and compact structure, which is applied in the direction of transformer/inductor cooling, transformer/inductor coil/winding/connection, electrical component structure association, etc., and can solve loose coil winding, affect equipment operation, safety hazards, etc. problem, achieve the effect of preventing arc, improving service life, taking into account energy saving and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

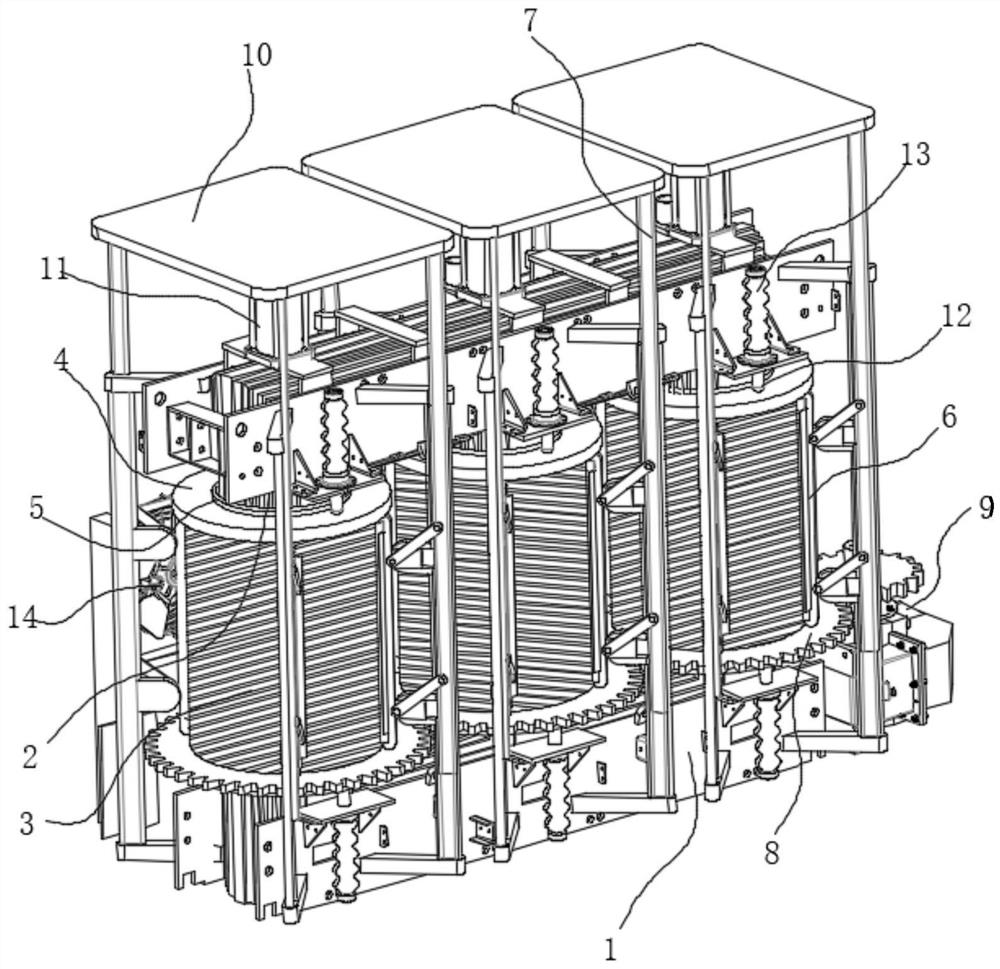

[0030] see figure 1 , In the embodiment of the present invention, a dry-type transformer with a coil compression structure includes a bracket 1, at least two iron cores 2 are distributed between the brackets 1, and each of the iron cores 2 is connected up and down and is surrounded by a peripheral sleeve. A coil 3 is provided, wherein the upper and lower ends of the coil 3 are fixed with a connecting ring 4, and the connecting ring 4 is rotatably connected to the iron core 2 through an insulating sleeve 5;

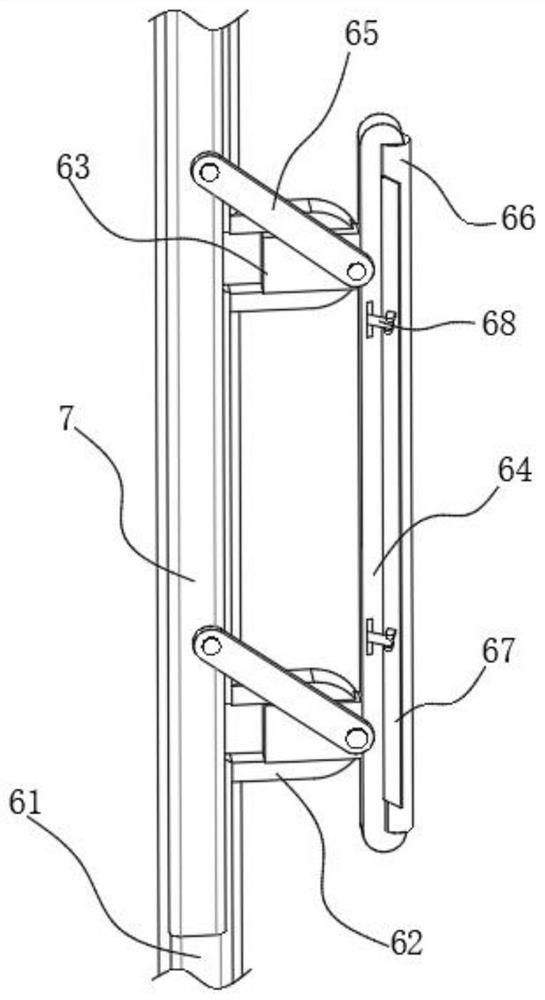

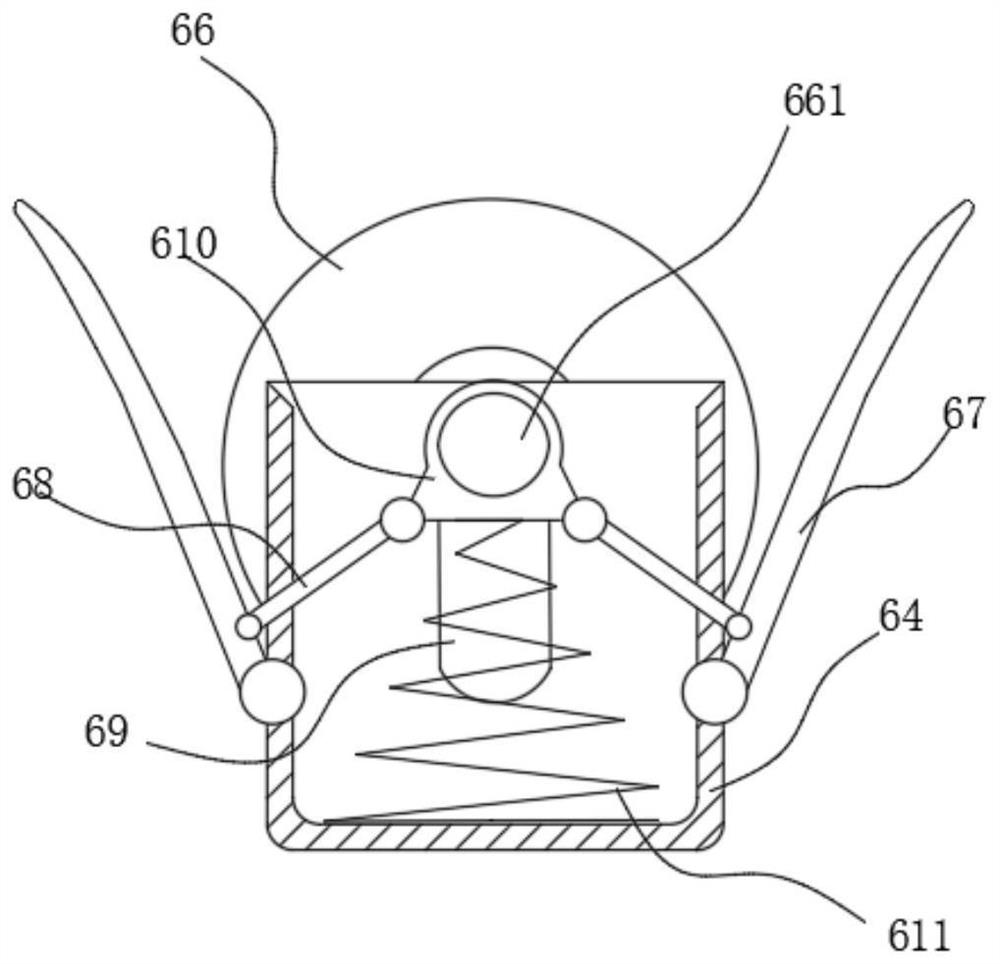

[0031] A plurality of pressing assemblies 6 are distributed around the periphery of each of the coils 3 , and the pressing assemblies 6 are connected to the bracket 1 . The pressing assemblies 6 can adjust the strength of pressing the coils 3 through the adjusting rod 7 .

[0032] In this embodiment, the upper end of the insulating sleeve 5 located at the bottom of each coil 3 is fixedly sleeved with a ring gear 8, and the ring gears 8 in the adjacent two coils 3 mesh with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com