Recycling process of polyaluminium chloride filter residue

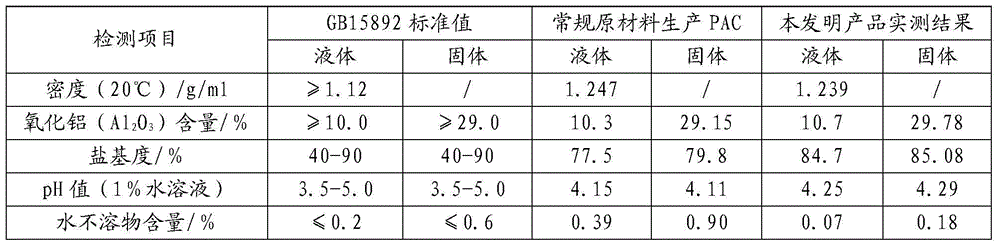

A technology of polyaluminum chloride and filter residue, applied in aluminum chloride, aluminum halide and other directions, can solve problems such as waste of resources, and achieve the effects of reduced manufacturing cost, low water-insoluble matter content, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

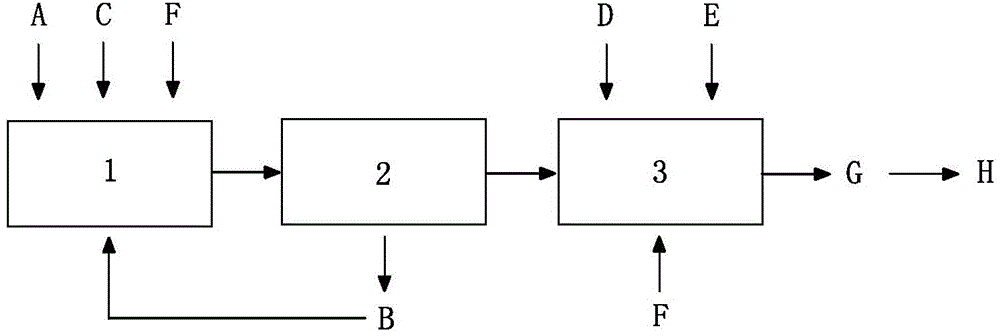

Method used

Image

Examples

Embodiment 1

[0027] 1) In the primary reactor 1 (acid-resistant reaction vessel with stirring device and utilizing steam heating), 175 parts of appropriate amount of water F and industrial hydrochloric acid A are added while stirring, and it is mixed with a hydrochloric acid solution whose volume concentration is 23%; Add 35 parts of filter residue B under normal temperature and stir until filter residue B completely dissolves into a slurry; raise the temperature to 60-80°C, start adding 110 parts of aluminum-containing waste residue C, and continue to heat up during the adding process, and wait for aluminum-containing waste residue C to be added After the addition is complete, the temperature of the feed liquid system is controlled at 95-115° C., and the reaction is carried out for 3 hours under normal pressure; the salinity of the feed liquid in the primary reaction kettle is controlled at 27% ± 10%;

[0028] 2) The feed liquid after reaction is carried out liquid slag separation by liqu...

Embodiment 2

[0031] 1) In the primary reaction kettle 1 (acid-resistant reaction vessel with stirring device and utilizing steam heating), add an appropriate amount of water F and 185 parts of industrial hydrochloric acid A while stirring to prepare a hydrochloric acid solution with a volume concentration of 25%; Add 45 parts of filter residue B under normal temperature and stir until filter residue B completely dissolves into a slurry; raise the temperature to 60-80°C, start adding 90 parts of aluminum-containing waste residue C, and continue to heat up during the adding process, and wait for aluminum-containing waste residue C to be added After the addition is completed, the temperature of the feed liquid system is controlled at 95-115° C., and the reaction is carried out for 4 hours under normal pressure; the salinity of the feed liquid in the primary reaction kettle is controlled at 27% ± 10%;

[0032] 2) The reacted feed liquid is separated from the liquid slag through the plate and f...

Embodiment 3

[0035] 1) In the primary reaction kettle 1 (acid-resistant reaction vessel with stirring device and utilizing steam heating), add an appropriate amount of water F and 200 parts of industrial hydrochloric acid A while stirring, and prepare a hydrochloric acid solution with a volume concentration of 27%; Add 60 parts of filter residue B under pressure and normal temperature, stir until filter residue B is completely dissolved into a slurry; raise the temperature to 60-80°C, start adding 80 parts of aluminum-containing waste residue C, continue to heat up during the adding process, wait for aluminum-containing waste residue C to be added After the addition is complete, the temperature of the feed liquid system is controlled at 95-115° C., and the reaction is carried out for 4 hours under normal pressure; the salinity of the feed liquid in the primary reaction kettle is controlled at 27% ± 10%;

[0036] 2) The feed liquid after the reaction is separated by pressure filtration of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com