Movable micro turbine jet engine test bed

A jet engine and micro-turbine technology, applied in the direction of internal combustion engine testing, etc., can solve problems such as poor flexibility and immovability of small test benches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

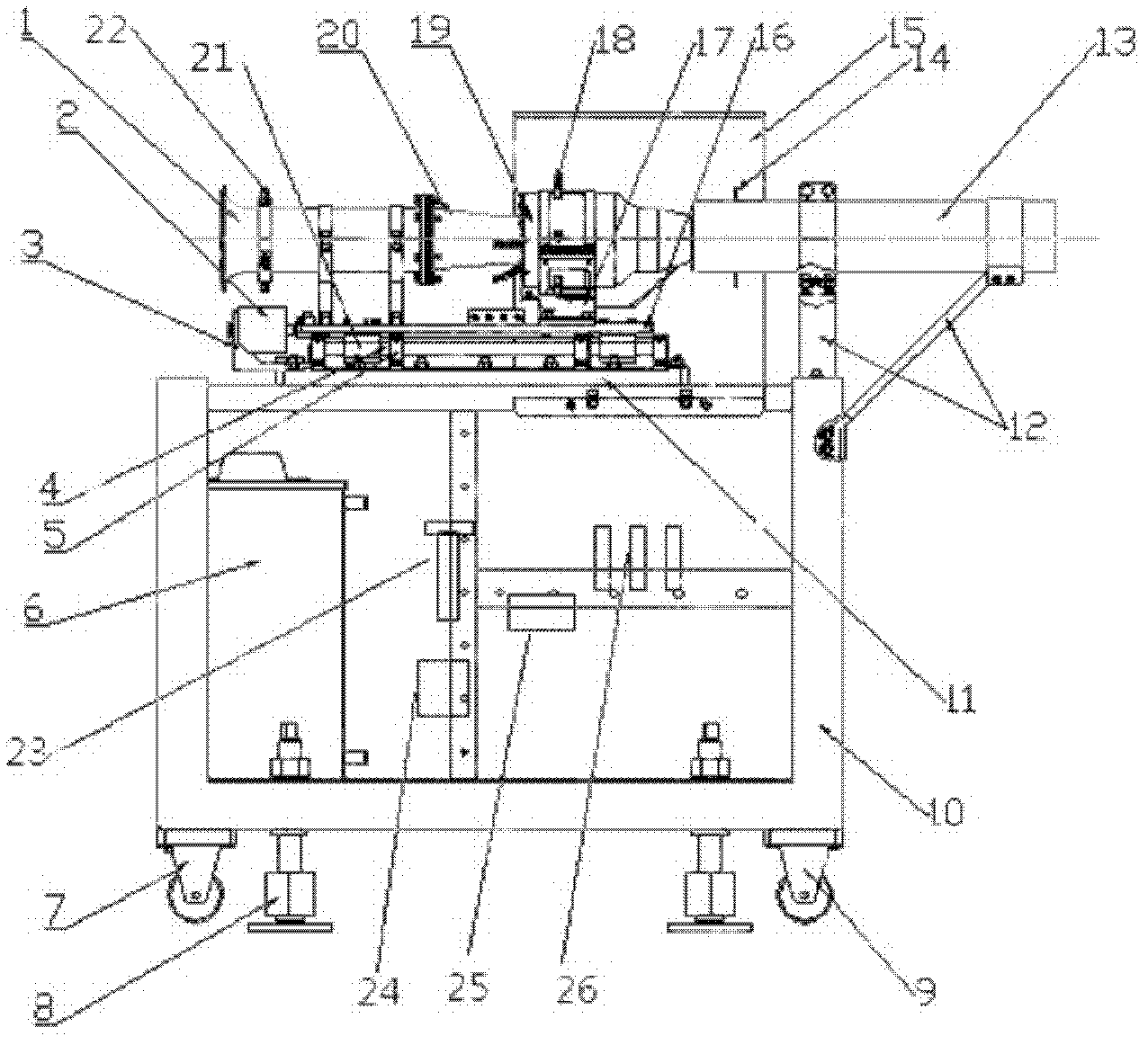

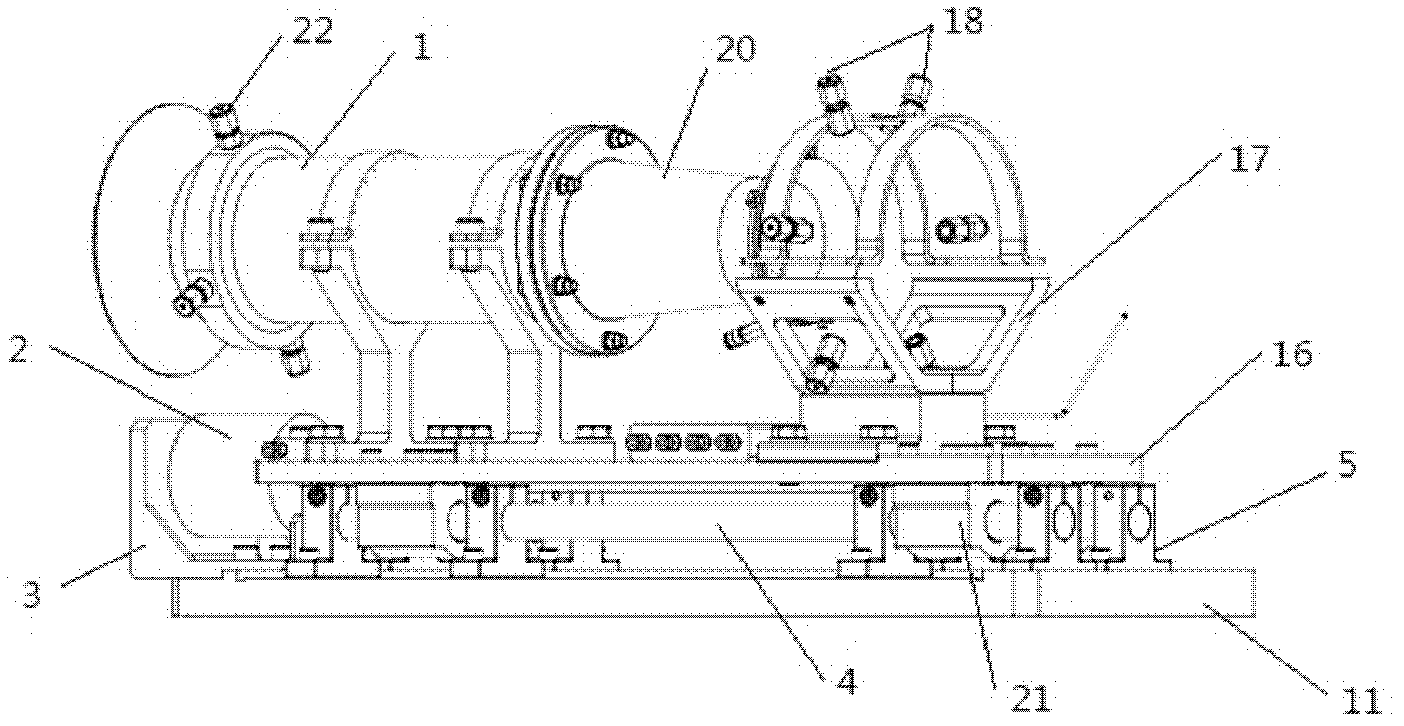

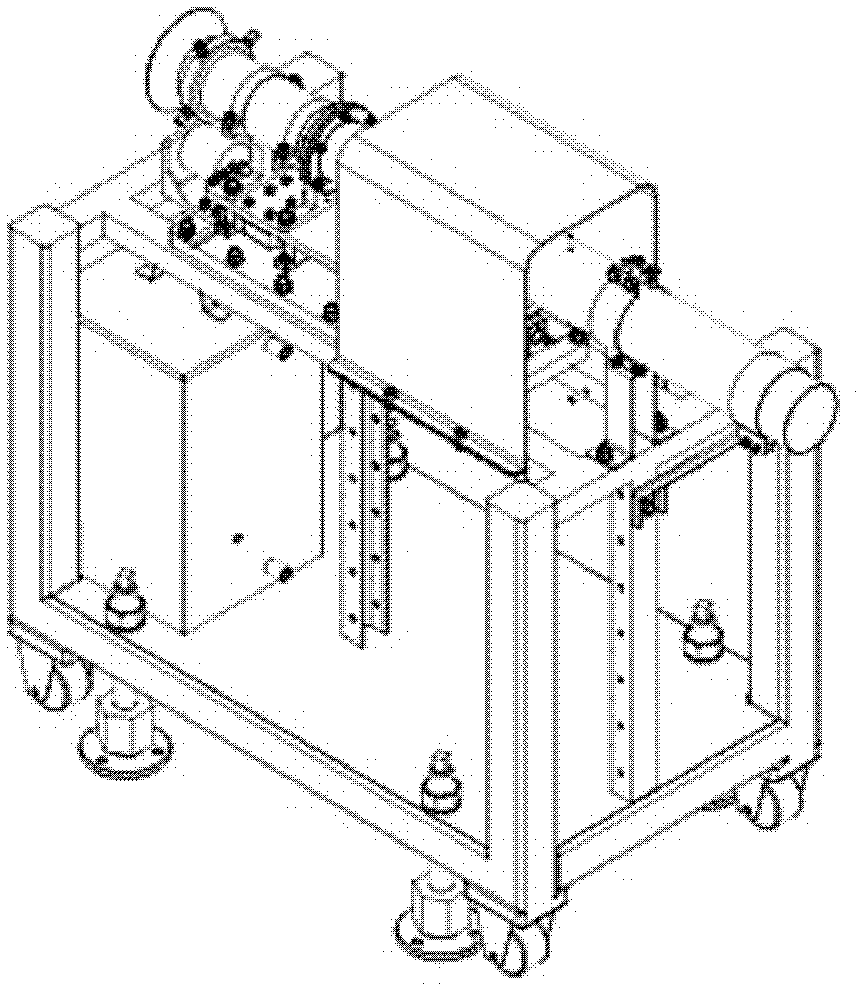

[0026] A movable miniature turbojet engine test stand of the present invention is composed of two parts, a test stand and a control cabinet. connected; the control cabinet is equipped with various instruments and computers to receive experimental data and control the running state of the micro turbojet engine.

[0027] See figure 1 , the test bench is an open structure, which is convenient for understanding and observing the connection method and theme structure of various sensors. It consists of a flow measuring tube 1, a load cell 2, a load cell bracket 3, a slide rail shaft 4, a slide rail shaft support 5, an oil tank 6, a moving wheel 7, a screw support 8, a fixed wheel 9, and a main support steel frame 10 , fixed plate 11, tail nozzle bracket 12, tail nozzle 13, temperature sensor 14, protective cover 15, slide plate 16, engine support seat 17, temperature sensor and pressure measuring joint 18, micro turbojet engine 19, front inner guide Flow cover 20, sliding plate co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com