Waste automobile shell shredding recovery equipment

A technology of automobile casing and recycling equipment, which is applied in the field of equipment that splits materials into pieces by tearing parts, can solve the problems of low production efficiency, and achieve the effects of small processing resistance, uniform output size, and high shredding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

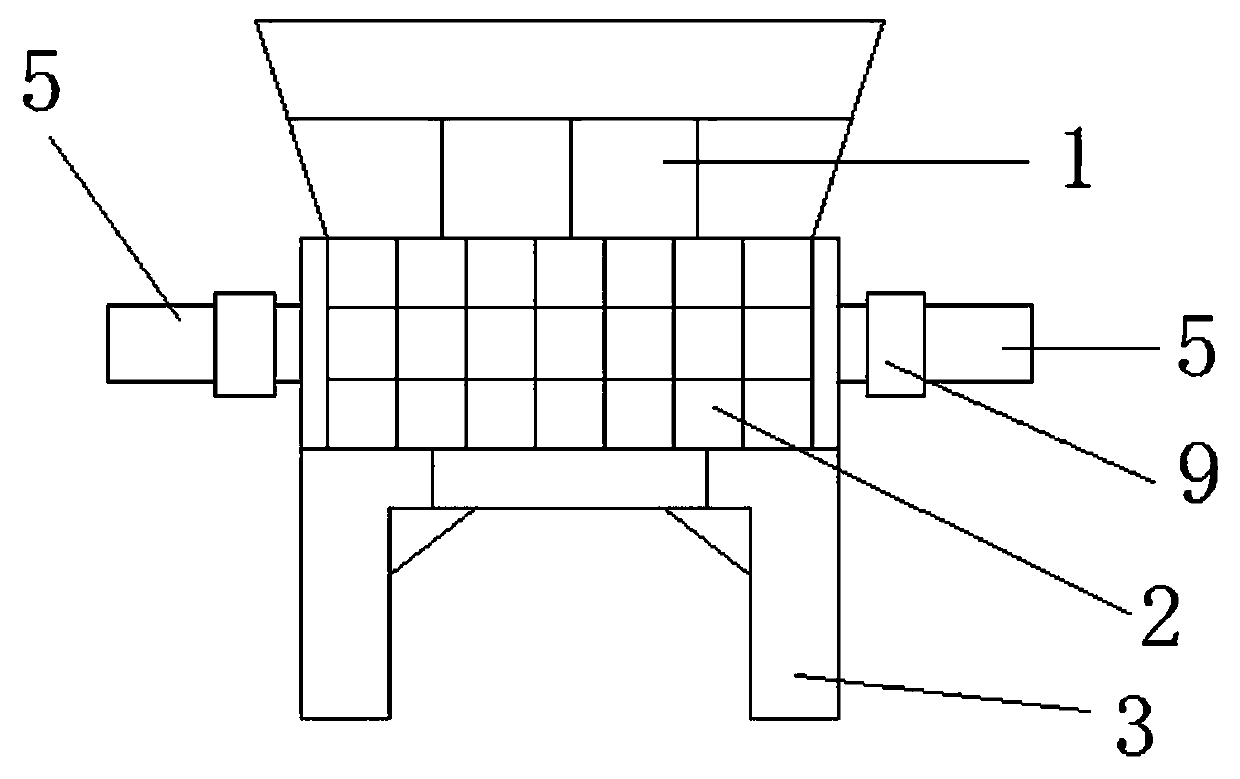

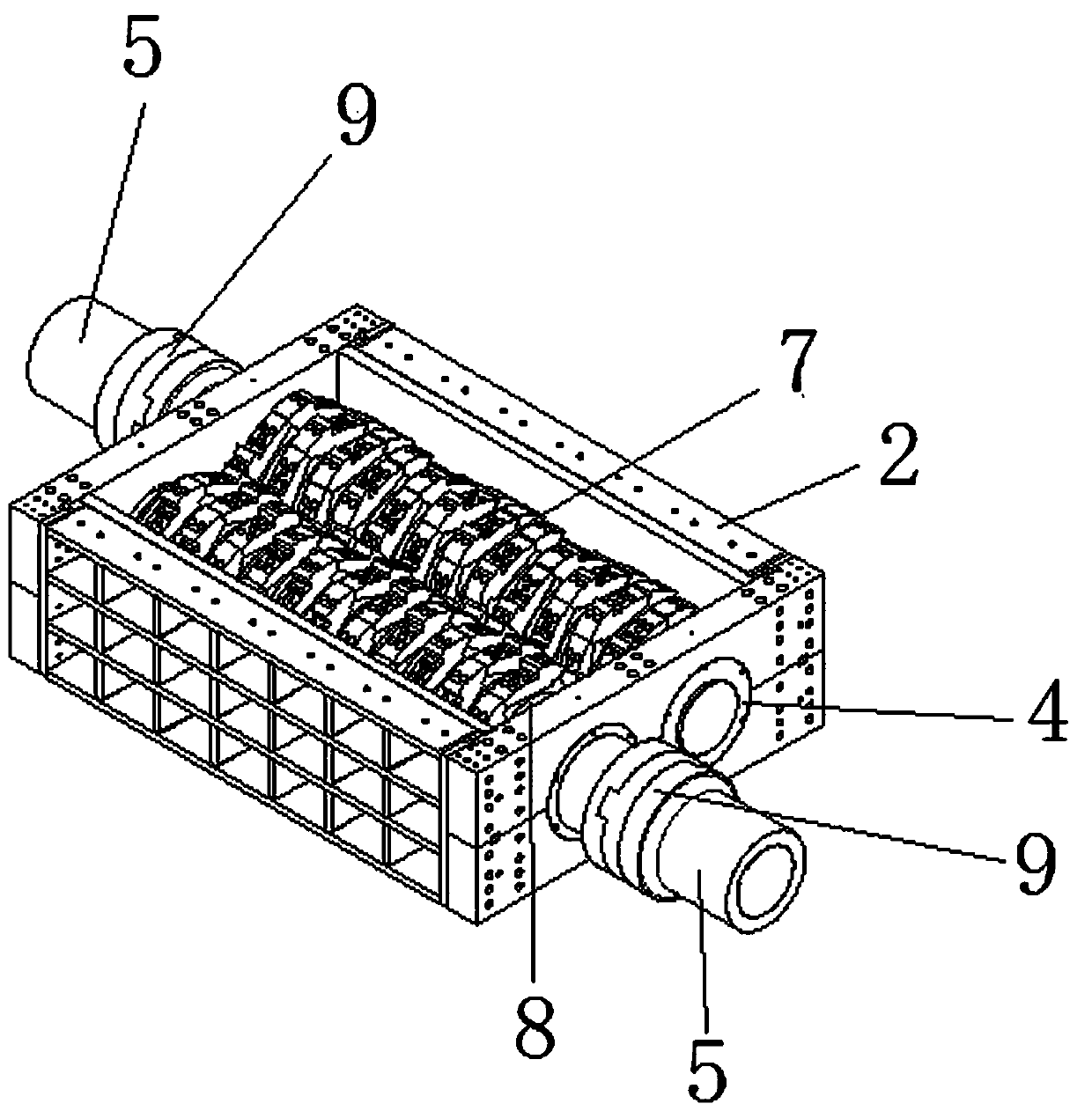

[0019] Embodiment 1: as figure 1 -shown in -6, a kind of waste automobile casing shreds recovery equipment, comprises drop hopper 1, crushing box 2, frame 3 and conveying line, described frame 3 top is provided with crushing box 2, and the top of crushing box 2 is provided with A conveying line is arranged below the falling hopper 1 and the crushing box 2, and two cutter shafts 5 arranged in parallel and rotating in opposite directions are arranged horizontally through bearings 4 in the crushing box 2.

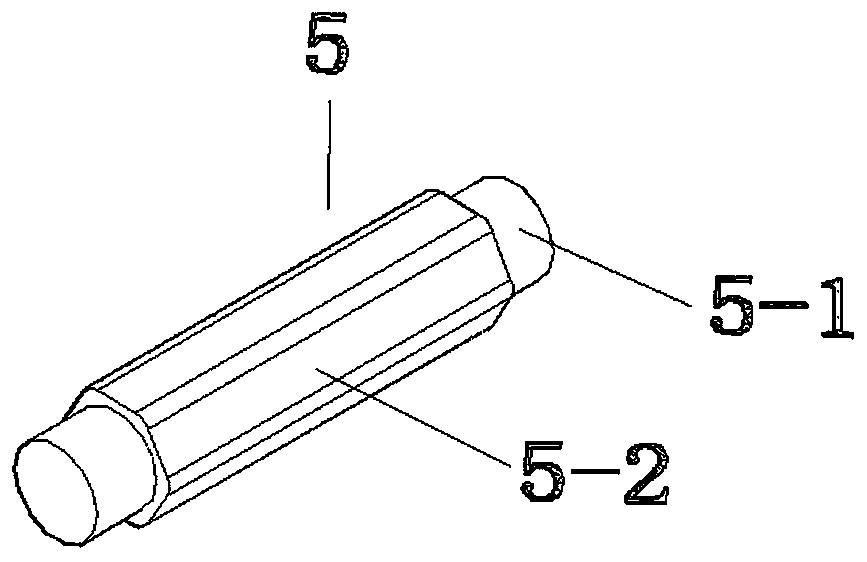

[0020] The cutter shaft 5 is provided with a bearing installation section 5-1 and a blade installation section 5-2, the section of the blade installation section 5-2 is a regular hexagon, and the axial direction of the cutter shaft 5 is arranged with first knives Body 11, the second cutter body 12, the third cutter body 13 and the fourth cutter body 14, spacer ring 7 for isolation is installed between adjacent two cutter bodies, the installation width of cutter body and spacer...

Embodiment 2

[0023] Embodiment 2: as figure 1 -shown in -6, a kind of waste automobile casing shreds recovery equipment, comprises drop hopper 1, crushing box 2, frame 3 and conveying line, described frame 3 top is provided with crushing box 2, and the top of crushing box 2 is provided with A conveying line is arranged below the falling hopper 1 and the crushing box 2, and two cutter shafts 5 arranged in parallel and rotating in opposite directions are arranged horizontally through bearings 4 in the crushing box 2.

[0024] The cutter shaft 5 is provided with a bearing installation section 5-1 and a blade installation section 5-2, the section of the blade installation section 5-2 is a regular hexagon, and the axial direction of the cutter shaft 5 is arranged with first knives Body 11, the second cutter body 12, the third cutter body 13 and the fourth cutter body 14, spacer ring 7 for isolation is installed between adjacent two cutter bodies, the installation width of cutter body and spacer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com