Sewage recycling and regenerating combined equipment

A combined equipment and resource-based technology, applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. To achieve high-efficiency recycling, enhance the rate of biochemical reactions, and improve the efficiency of biochemical degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

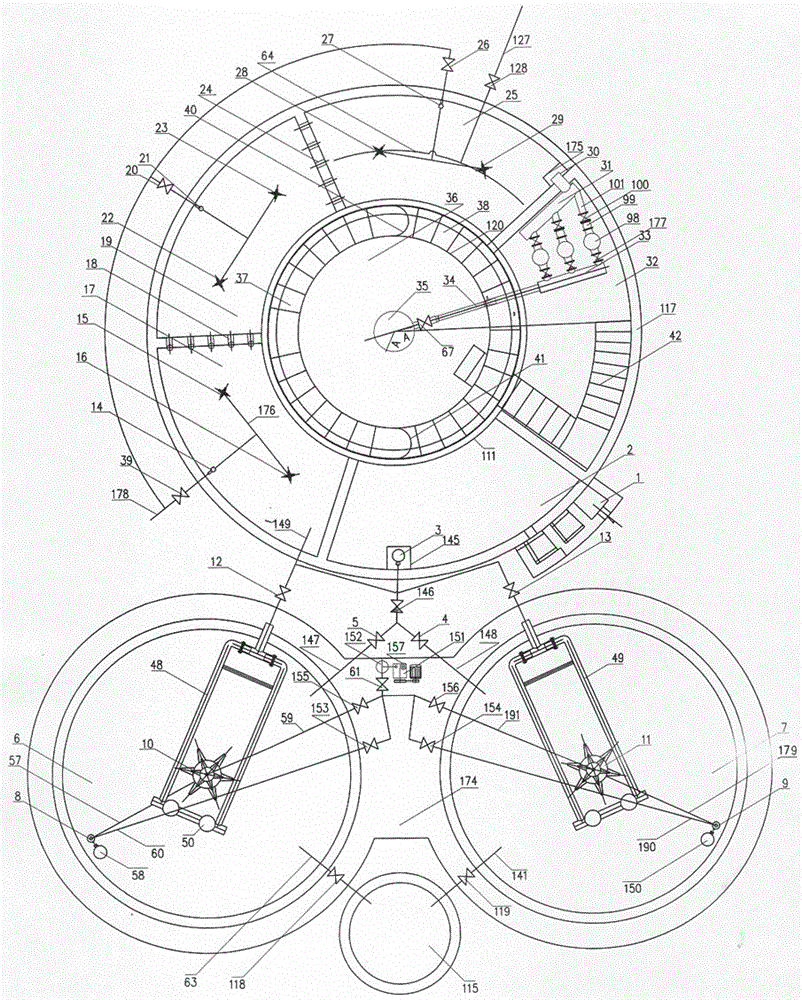

[0049] As shown in the accompanying drawings, a sewage resource regeneration treatment combination equipment includes a biochemical reactor 36, a cylindrical foundation 111, a plate foundation 112, a crypt machine room 116, an outer crypt machine room 32, an annular pool wall 117, biological sand Filter box 37, semicircular partitions 40, 41, biological activated carbon expanded bed 38, sump 2, SBR6, 7, BAF17, 19, 25 and mud thickening tank 115,

[0050] The wall of each unit of the combined sewage resource regeneration treatment device is circular, semicircular or arc-shaped, and the cylinder wall 120 of the biochemical reactor 36 serves as the biological sand filter box 37, biological activated carbon expansion The common wall of the bed 38, the BAF17, 19, 25, the sump 2, and the outer ring crypt machine room 32 are arranged between the cylindrical foundation 111 and the annular pool wall 117, and the semicircular partitions 40, 41 constitute the biological sand filter. Betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com