Chopping softening system for fresh fruit

A technology for dicing and fresh fruit, applied in juice extraction, food science, application and other directions, can solve the problems of small probability of small pieces of fresh fruit by the reamer, large working resistance of the reamer bin, and low work efficiency, etc. The effect of reducing machining resistance and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

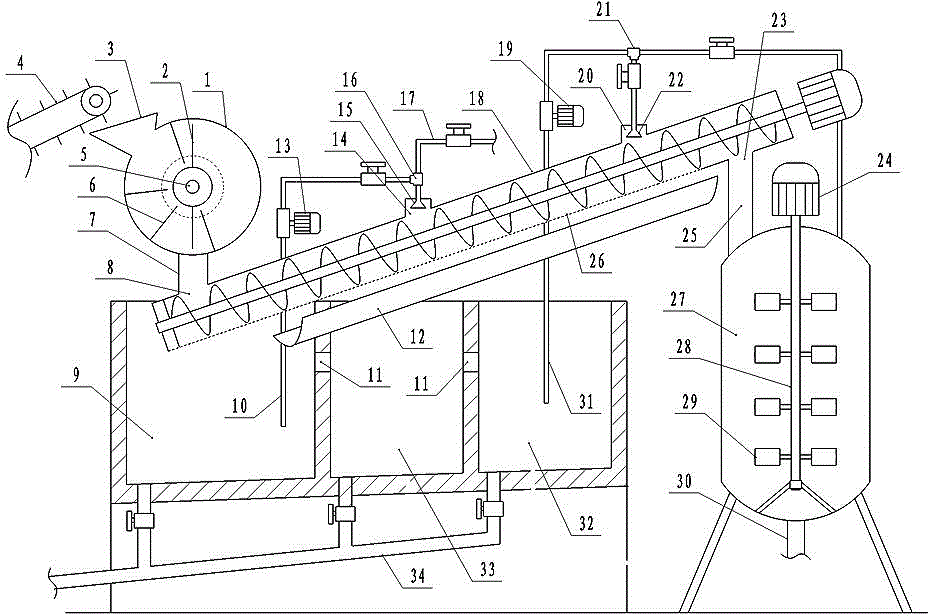

[0007] Examples such as figure 1 As shown, a fresh fruit cutting and softening system is composed of four parts: a fresh fruit cutting device, a conveying device, a cleaning device and a pulp softening device. A feeding hopper is designed above the cylindrical cutting chamber 1 of the fresh fruit cutting device 3. A discharge pipe 7 is designed at the bottom, a fresh fruit conveyor belt 4 is installed above the feed hopper 3, a fixed knife 6 is installed in the cutting bin 1, and a moving knife 2 is installed on the rotating shaft 5 at the center of the cutting bin 1. The knife 2 passes through the gap of the fixed knife 6 when it rotates; the conveying device is mainly composed of a spiral conveying pipe 18, and the lower side pipe wall of the spiral conveying pipe 18 has a filter hole 26, and the inlet 8 at the lower end and the discharge pipe 7 connections, the lower water spray port 14 and the upper water spray port 20 are opened on the top of the middle part, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com