Tearing, milling and fragmenting device for machining hard solids in kitchen waste

A technology of food waste and chemical equipment, which is applied in the direction of grain processing, etc., can solve the problems of broken bowls and glass pieces, food waste crushing, solid-liquid separation, etc., and achieve the effect of reducing processing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

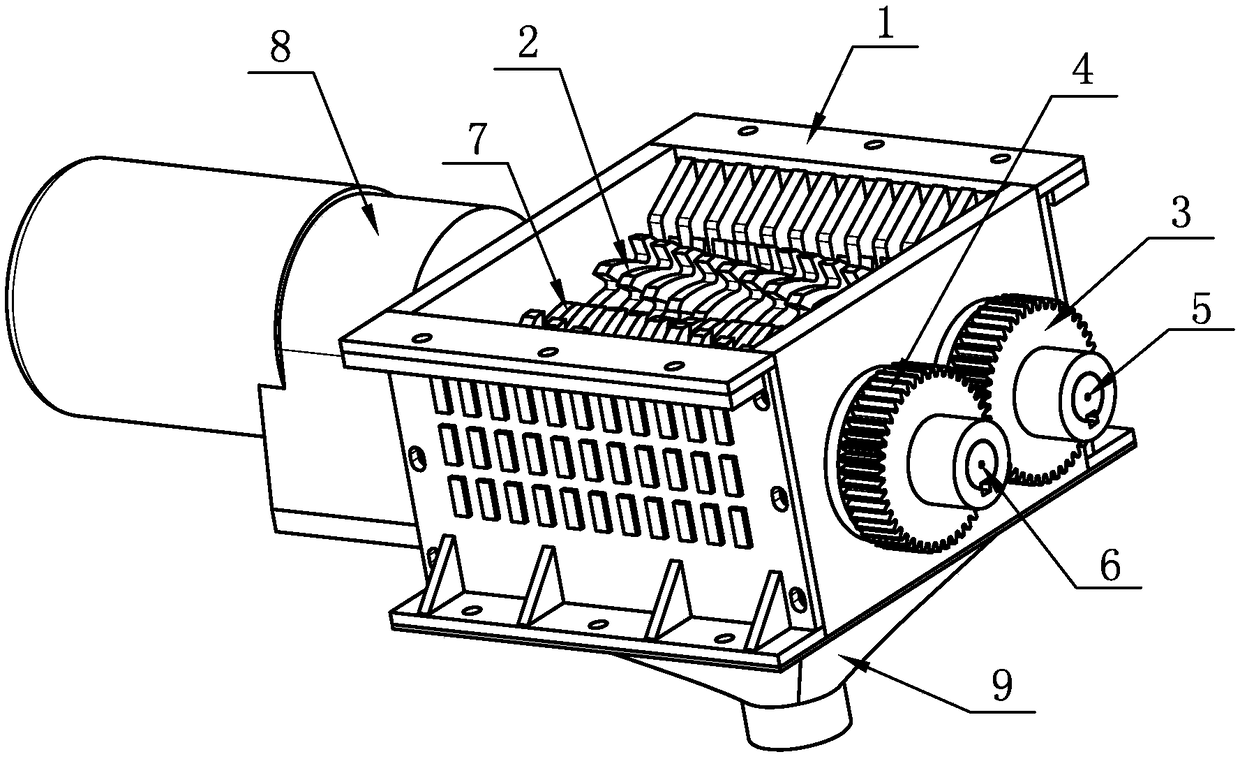

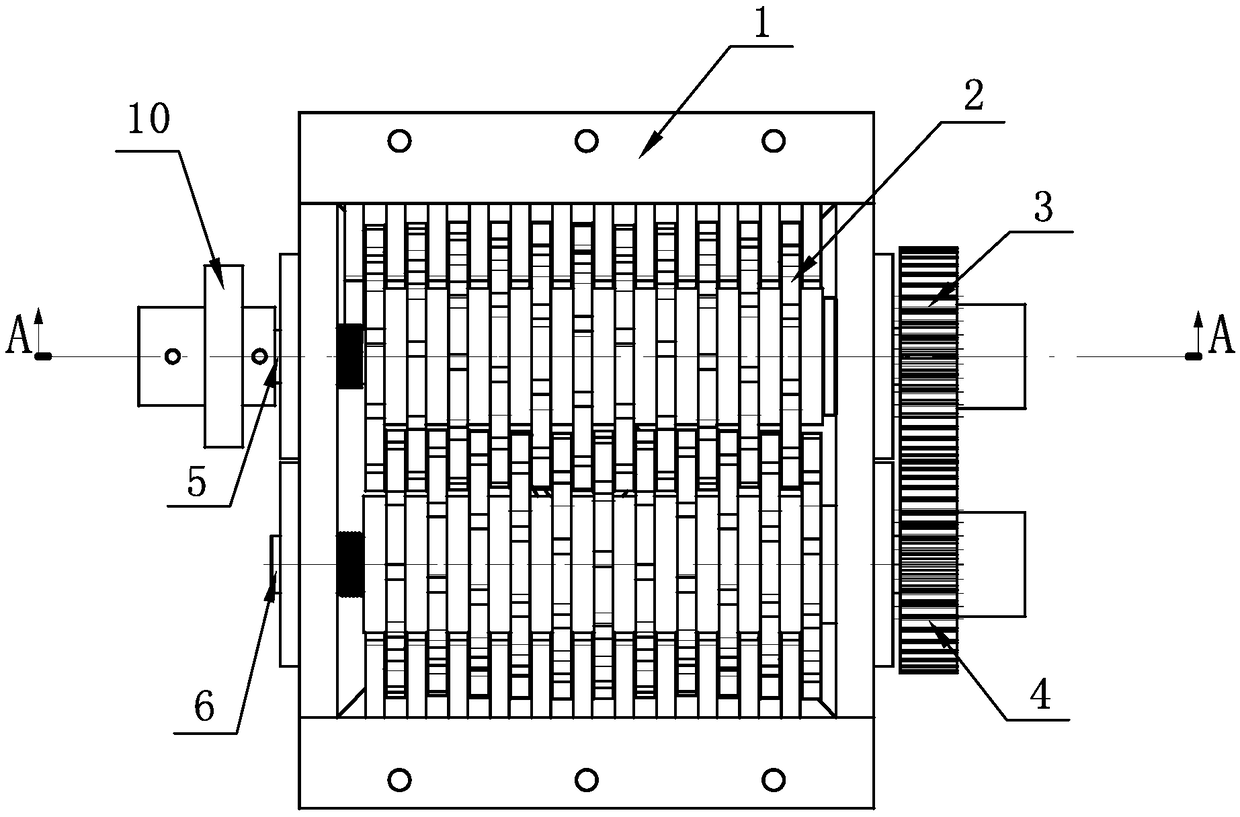

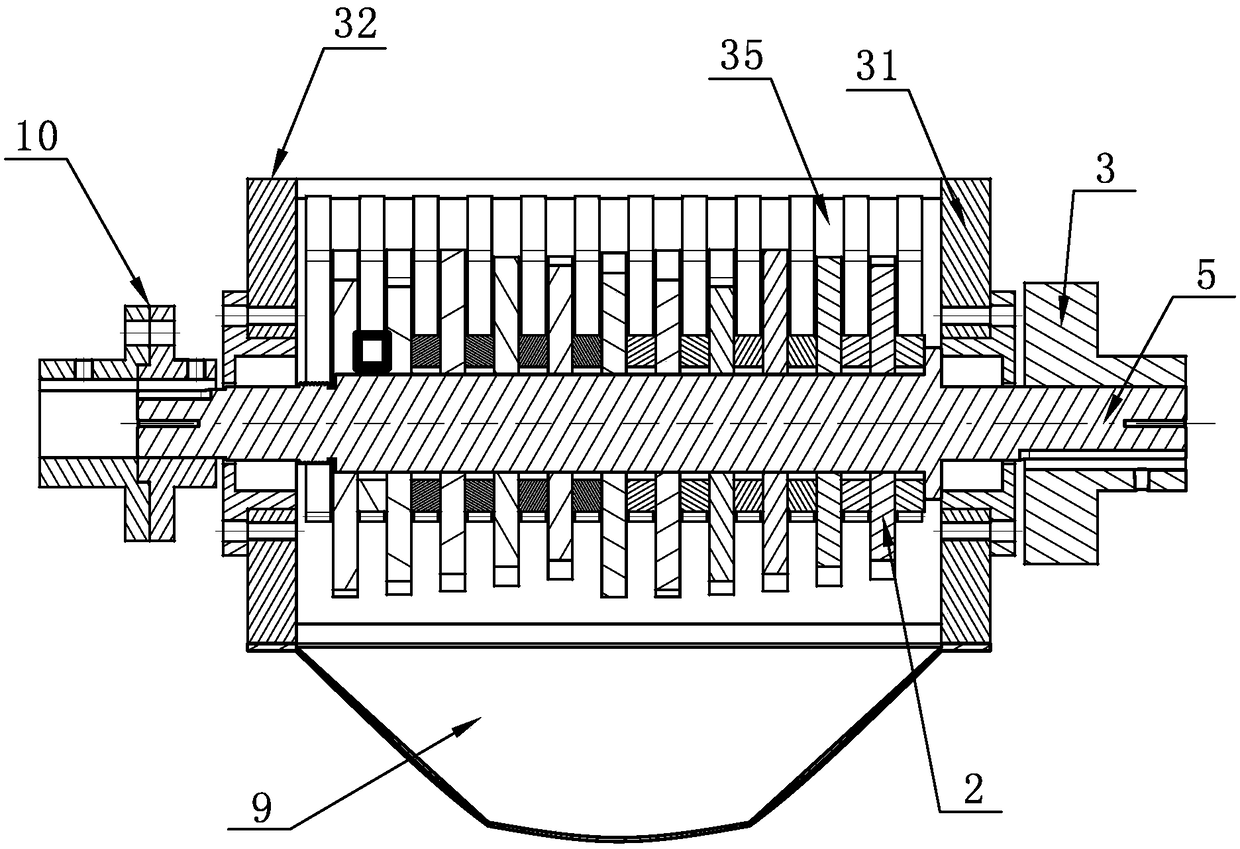

[0024] A hard solid object tearing and crushing device for processing food waste, such as Figure 1-Figure 6 As shown, it includes a shredding box body 1, a driving knife group 2, a driving wheel 3, a driven wheel 4, a driving shaft 5, a driven shaft 6, a driven knife group 7 and a shredding driving part 8, and the shredding box body 1. It includes a front side plate 31, a rear side plate 32, a left side plate 33, a right side plate 34, a left side sub knife plate 35 and a right side side knife plate 36. The front side plate 31 and the rear side plate 32 are arranged in parallel, and the left side The plate 33 and the right side plate 34 are arranged between the front side plate 31 and the rear side plate 32 respectively, and the four form a frame body with openings at both ends. The shaft installation hole system 37 and the driven shaft installation hole system 38 are provided with a left auxiliary knife plate 35 on the inner side of the left side plate 33, and a right side a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com