Preparing method of small-specification pure niobium bar with well-closed formation

A technology with uniform structure and small size, which is used in the field of preparation of small size pure niobium bars, which can solve the problems of easy wire breakage and poor structure uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

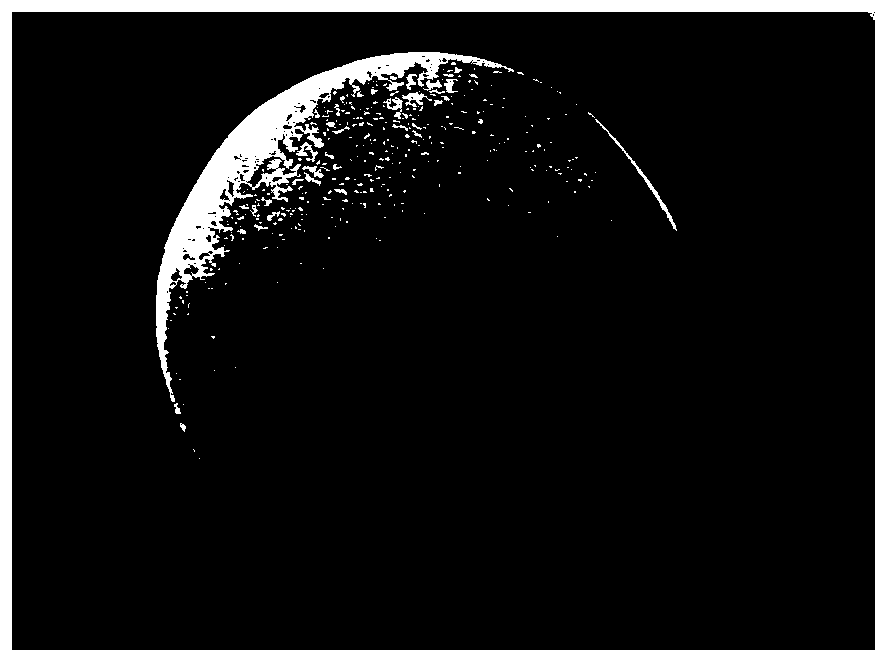

Image

Examples

Embodiment 1

[0040] The present invention adopts a kind of preparation method of uniform small-scale pure niobium bar material, specifically implements according to the following steps:

[0041] A pure niobium billet with a diameter of Φ85mm was selected, and at room temperature, that is, 25°C, it was precision forged into a Φ45mm billet with one fire and three passes at room temperature, with a total deformation of 72.0%.

[0042] Carry out recrystallization annealing heat preservation in the vacuum annealing furnace, the temperature is 900 ℃, and the vacuum degree of the heat preservation stage is 0.5*10 -2 Pa, the holding time is 120min.

[0043] Place the bar billet in a box-type resistance furnace at room temperature, that is, 25°C, and roll it on a transverse rolling mill to a finished billet with a size of Φ7.0mm, rolling for 18 passes, and the cumulative deformation of rolling is 97.6%; The pass type of the tandem rolling mill during rolling deformation is round-flat-square.

[0...

Embodiment 2

[0046] The present invention adopts a kind of preparation method of uniform small-scale pure niobium bar material, specifically implements according to the following steps:

[0047] Select a pure niobium billet with a specification of Φ100mm, place it in a box-type resistance furnace and heat it to 500°C, and use 1 fire and 5 passes for precision forging into a Φ45mm specification rolling billet, and the cumulative deformation of precision forging is 80.0%;

[0048] Use a vacuum annealing furnace for recrystallization annealing heat preservation, the annealing heat preservation temperature is 1200 ℃, and the vacuum degree in the heat preservation stage is 10 -2 Pa, the holding time is 240min;

[0049] The bar billet is placed in a box-type resistance furnace and heated to 500°C, and rolled on a transverse rolling mill to a finished billet with a size of Φ27mm. The cumulative deformation of the 4 rolling passes is 64.0%, and the rolling deformation The pass type of the horizon...

Embodiment 3

[0052] Select a Φ95mm pure niobium precision forged billet, place it in a box-type resistance furnace, heat it to 500°C, hold for 90 minutes, and use 1 heat and 3 passes to forge a Φ45mm specification rolling billet. The total amount of deformation in the precision forging process is 77.6%.

[0053] Place the Φ45mm rolling billet in a vacuum annealing furnace, raise the temperature to 1100°C and keep it for 130 minutes, and then cool the furnace to room temperature before it is released from the furnace.

[0054] Place the bar billet in a box-type resistance furnace and heat it to 500°C, keep it warm for 60 minutes, and then roll it on a transverse rolling mill, and use one heat and multiple passes to obtain a Φ27mm finished billet with a certain structure; rolling The manufacturing pass is 4 passes, the deformation amount of each pass is 10% to 25%, and the cumulative deformation amount of 1 fire is 64.0%.

[0055] Place the rolled billet in a vacuum annealing furnace, raise t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com