Cylindrical sodium-sodium-air integrated heat exchanger

A heat exchanger and gas integration technology, applied in the field of reactor accident waste heat export, can solve the problems of high equipment cost, difficult installation, low heat transfer efficiency, etc. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

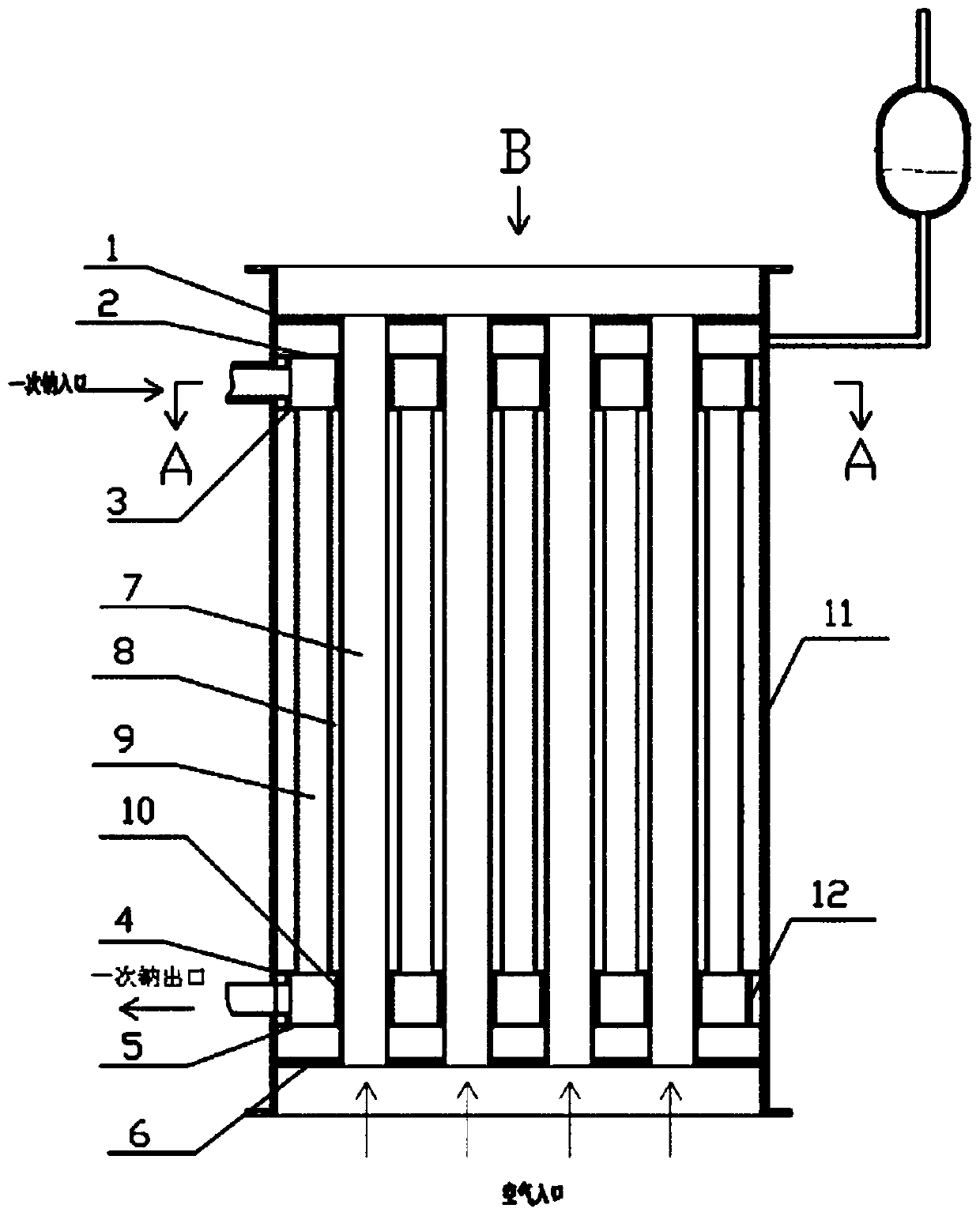

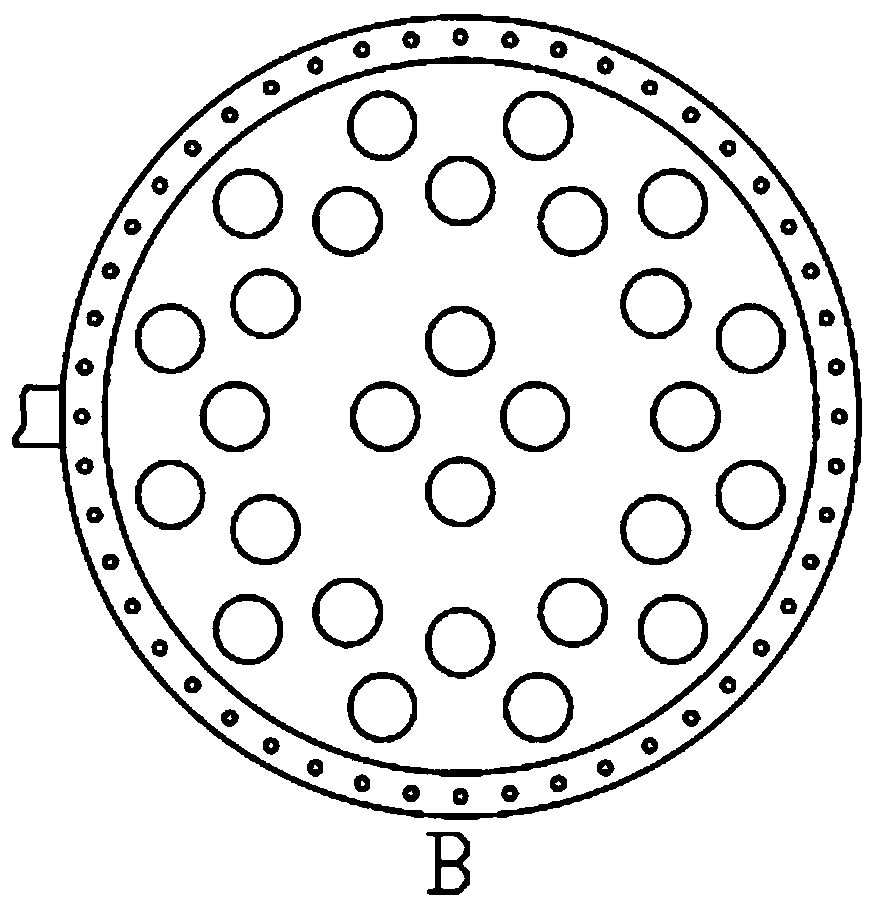

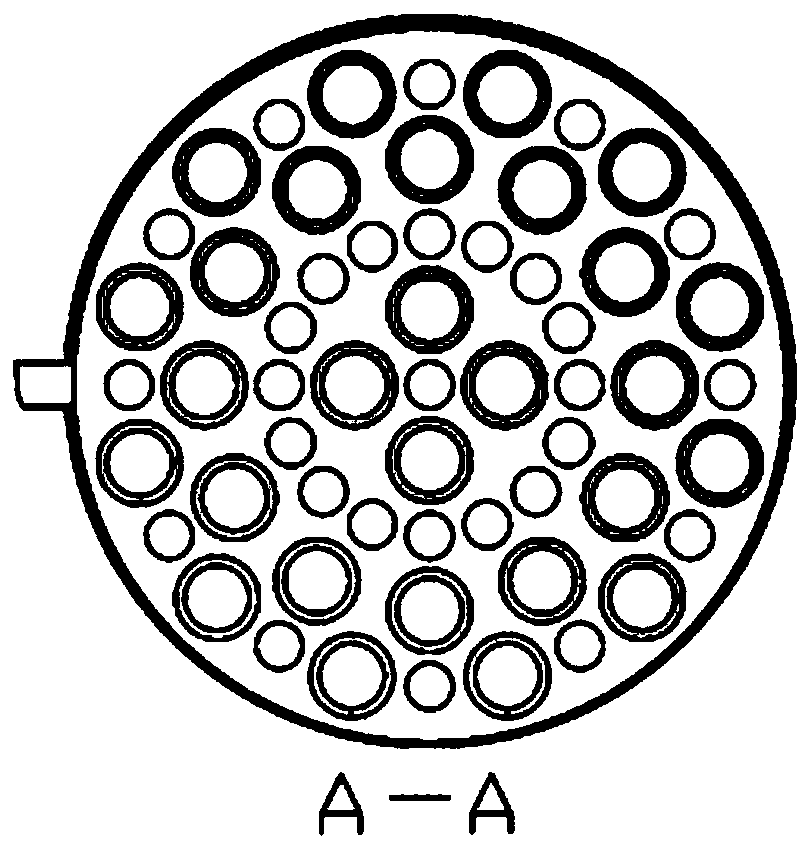

[0028] Such as Figure 1~3 As shown, a cylindrical tube sodium-sodium-gas integrated heat exchanger includes a tube body 11, a sodium-air heat transfer tube 7, and a sodium-sodium heat transfer tube 9, wherein the tube body 11 is a cylindrical tube structure. The upper and lower ends of the cylinder 11 are provided with a first layer of tube sheet 1 and a sixth layer of tube sheet 6 respectively, a total of two layers of tube sheets, and a number of vertically distributed tube sheets are arranged between the first layer of tube sheet 1 and the sixth layer of tube sheet 6 The sodium-air heat transfer tube 7 enables air to enter the sodium-air heat transfer tube 7 from the sixth tube sheet 6 and takes away the heat of the secondary side sodium filled with the outer wall of the sodium-air heat transfer tube 7; A third layer of tube sheet 3 and a fourth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com