Chinese chestnut shelling equipment and shelling technology

A technology of chestnut and shell, which is applied in the field of fruit peeling equipment and its process, can solve the problems of chestnut mechanical peeling and removing the inner skin, destroying the appearance of chestnut kernels, and large loss, etc. Quality, the effect of reducing water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

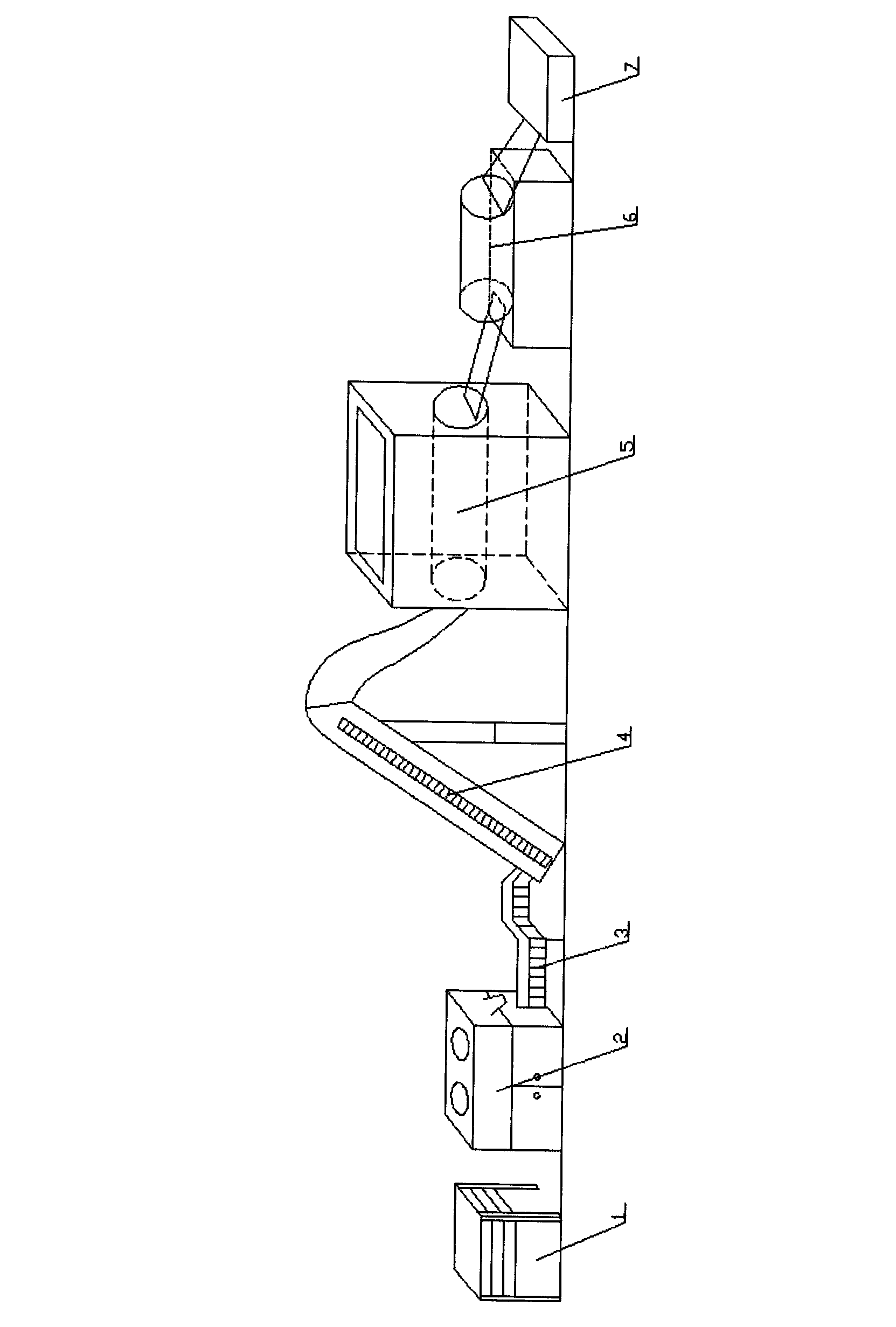

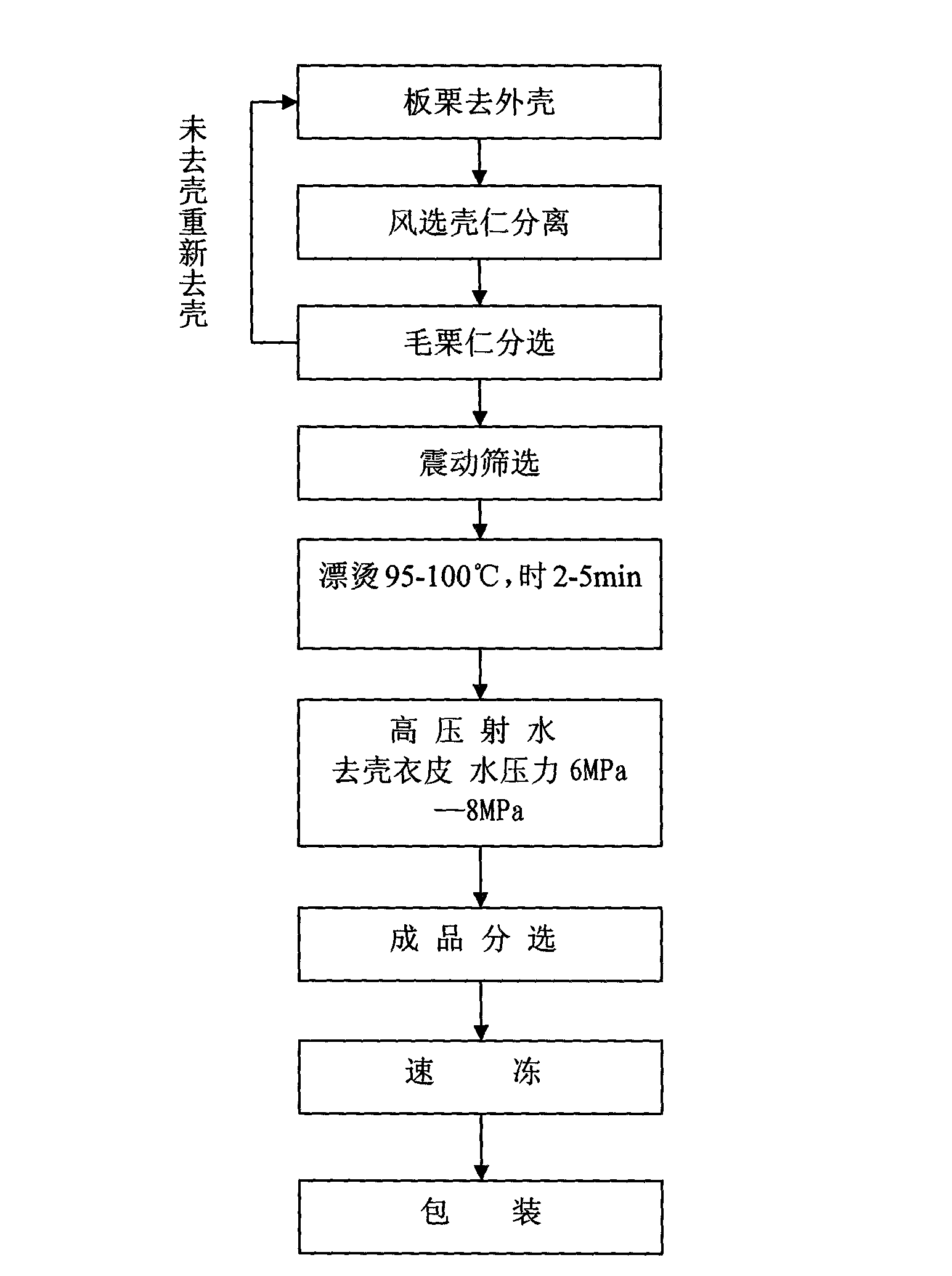

[0010] A chestnut shelling equipment is composed of a chestnut classifier, a sheller, a vibrating screening machine, a hoist, a spiral blanching machine, a high-pressure spray machine, and a washing machine connected in sequence. The shelling mechanism is composed of a motor driving a cutter head. It is characterized in that: after the chestnuts are graded and shelled, they enter the vibrating screening machine to screen and separate the residual shells, and then they are lifted into the spiral blanching machine and high-pressure spraying machine. The high-pressure spraying machine is composed of a screen drum and a high-pressure water nozzle. The angle between the water outlet of the nozzle and the tangent line of the drum circumference is adjustable, and the angle between the water outlet of the high-pressure water nozzle and the tangent line of the drum circumference is 15-20 degrees.

[0011] Chestnuts enter the cutter head from the hopper, and the cutter head rotates under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com