Ternary positive electrode material micron-sized platy monocrystal structure aggregate and preparation method thereof

A sheet-like single crystal, cathode material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of single crystal materials with good high voltage resistance, poor capacity and rate performance, and battery capacity attenuation, etc. Cyclic stability, shortening of processing time, effect of lowering melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

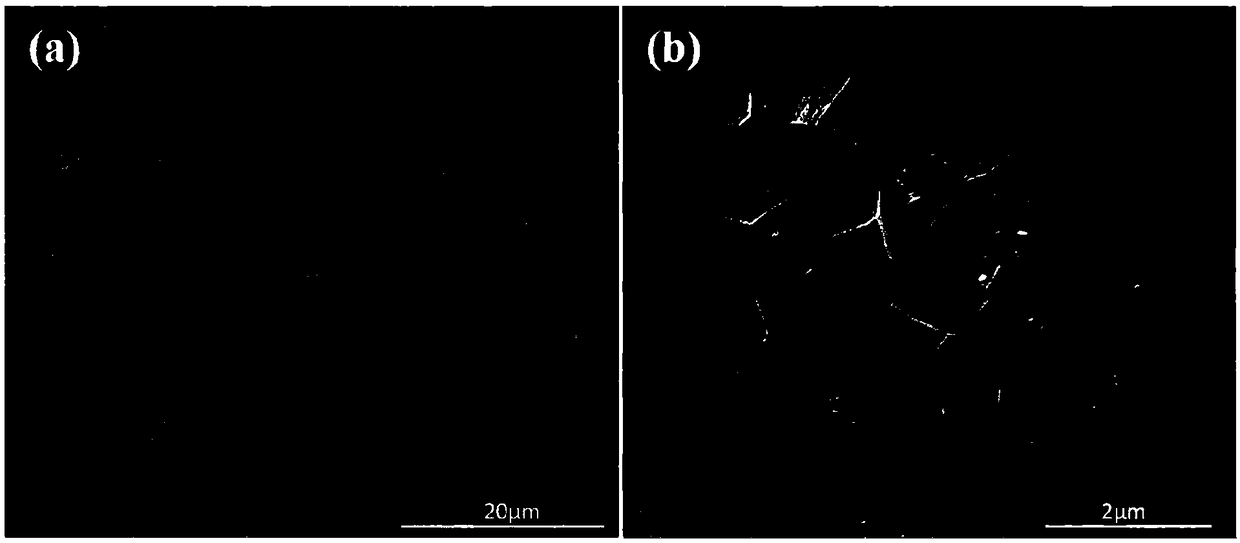

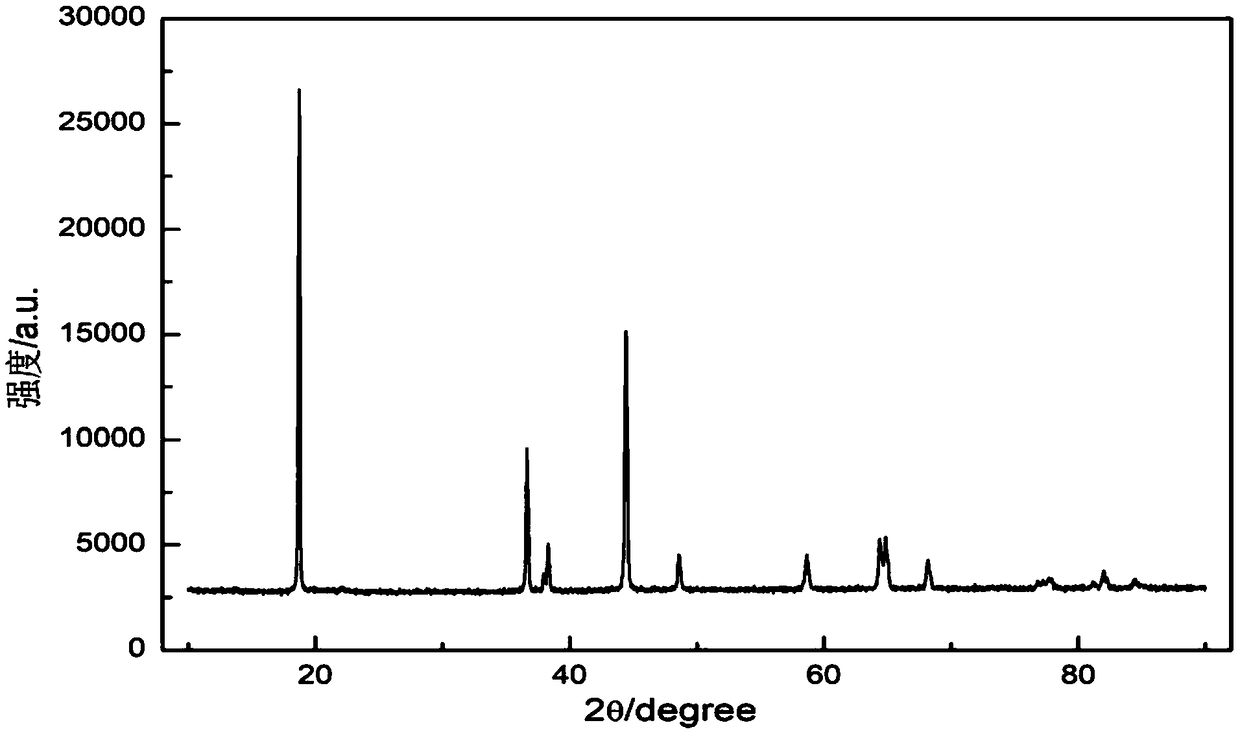

[0029] The micron-scale flake single crystal structure aggregate of the ternary positive electrode material prepared in this example has a main chemical formula of LiNi 0.6 co 0.2 mn 0.2 o 2 , also contains a small amount of doping element zirconium; the specific preparation method is as follows:

[0030] (1) Preparation of precursors: ① Weigh 2.4 mol of nickel sulfate, 0.8 mol of manganese sulfate, and 0.8 mol of cobalt sulfate, dissolve them in pure water, and prepare a 2-liter solution to obtain 2.0 mol / L of metal Salt solution A; ②Weigh 8.4mol of sodium hydroxide, dissolve it in pure water, and prepare 2 liters of aqueous solution to obtain a precipitant solution B with a concentration of 4.2mol / L; ③Use ammonia water as a complexing agent, take an appropriate amount thick ammonia water, add appropriate amount of pure water, and prepare 2 liters of 8mol / L ammonia solution C; Co-precipitation reaction; reaction parameters: stirring speed 400rpm, reaction system temperatu...

Embodiment 2

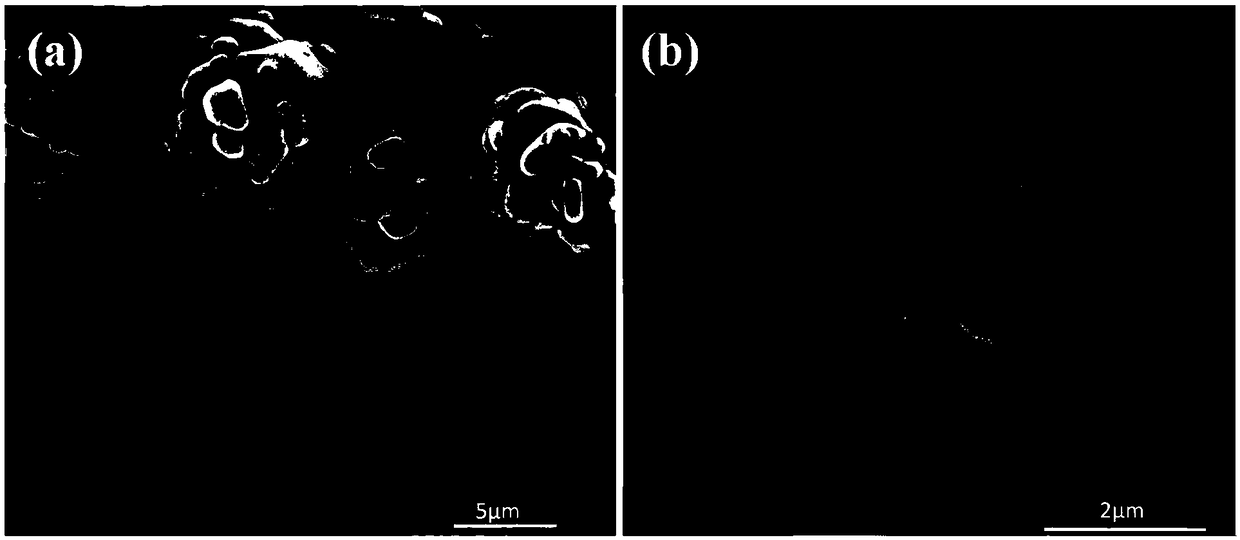

[0041] The micron-scale flake single crystal structure aggregate of the ternary positive electrode material prepared in this example has a main chemical formula of LiNi 0.5 co 0.2 mn 0.3 o 2 , also contains a small amount of doping element boron; the specific preparation method is as follows:

[0042] (1) Preparation of precursor: ① Weigh 2 mol of nickel sulfate, 0.8 mol of manganese sulfate, and 1.2 mol of cobalt sulfate, dissolve them in pure water, and prepare a 2-liter solution to obtain a 2.0 mol / L metal salt Solution A; 2. Weigh 8.4mol of sodium hydroxide, dissolve it in pure water, and prepare 2 liters of aqueous solution to obtain a concentration of 4.2mol / L precipitant solution B; 3. use ammonia as a complexing agent, take an appropriate amount of Concentrated ammonia water, add an appropriate amount of pure water, and prepare 2 liters of 8mol / L ammonia solution C; ④Pump the above metal salt solution A, precipitant solution B and ammonia solution C into the chemica...

Embodiment 3

[0048] The micron-scale flake single crystal structure aggregate of the ternary positive electrode material prepared in this example has a main chemical formula of LiNi 0.6 co 0.2 mn 0.2 o 2 , also contains a small amount of doping elements zirconium and aluminum, the specific preparation method is as follows:

[0049] (1) Preparation of precursors: Weigh 2.4mol of nickel sulfate, 0.8mol of manganese sulfate, and 0.8mol of cobalt sulfate, dissolve them in pure water, and prepare a 2-liter solution to obtain a 2mol / L metal salt solution A; 2. Weigh 8.4mol of sodium hydroxide, dissolve it in pure water, and prepare 2 liters of aqueous solution to obtain a concentration of 4.2mol / L precipitant solution B; 3. utilize ammonia water as a complexing agent, take an appropriate amount of concentrated Ammonia water, add an appropriate amount of pure water to prepare 2 liters of 6mol / L ammonia solution C; ④Pump the above metal salt solution A, precipitant solution B and ammonia soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com