SIP module partition electromagnetic shielding package method

A technology of electromagnetic shielding and packaging method, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of reducing cost, increasing the substrate area, disadvantage, etc., saving process technology, improving reliability, and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings and embodiments.

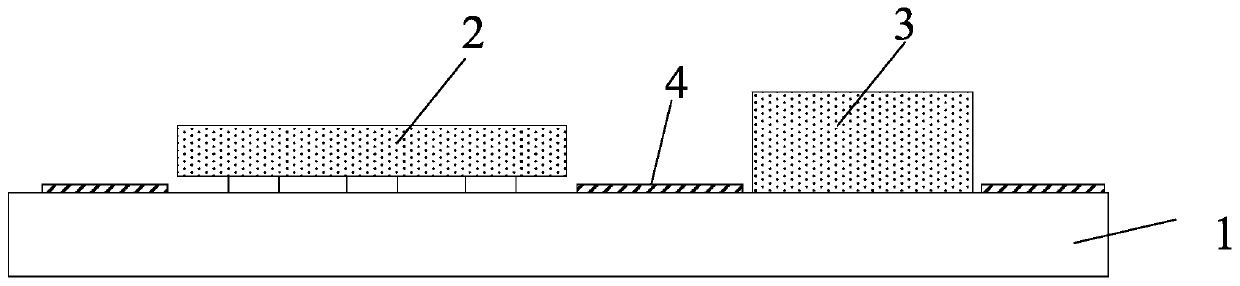

[0025] In step S1, a substrate 1 is provided, and the flip chip 2 and the passive component 3 are mounted on the first working surface of the substrate 1, and there are prefabricated grounding pads around the chip mounting position on the first working surface of the substrate 1. 4;

[0026] Among them, chip 2 is mounted by flip-chip welding;

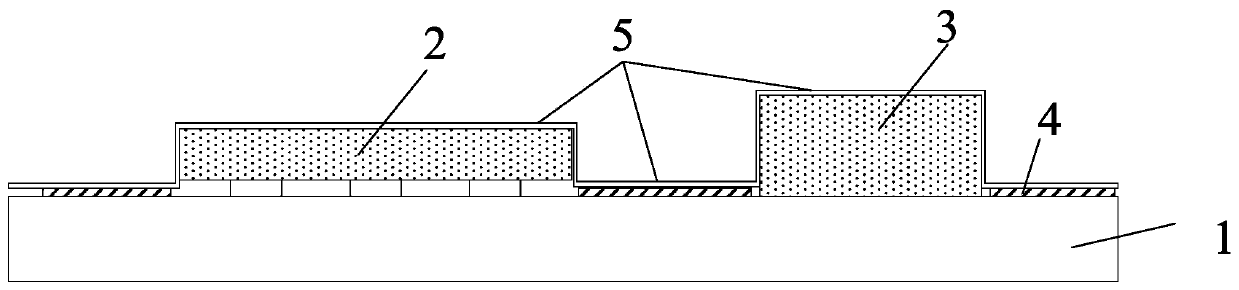

[0027] Step S2, then first perform plasma surface cleaning (Plasma surface cleaning) on the substrate 1, then use a vacuum lamination (Lamination) machine, and then perform film plastic sealing on the first working surface of the substrate 1 to form a cover on the first working surface of the substrate 1 plastic film 5;

[0028] Thus, the chip 2, the passive element 3, and the ground pad 4 are all covered by the plastic film 5;

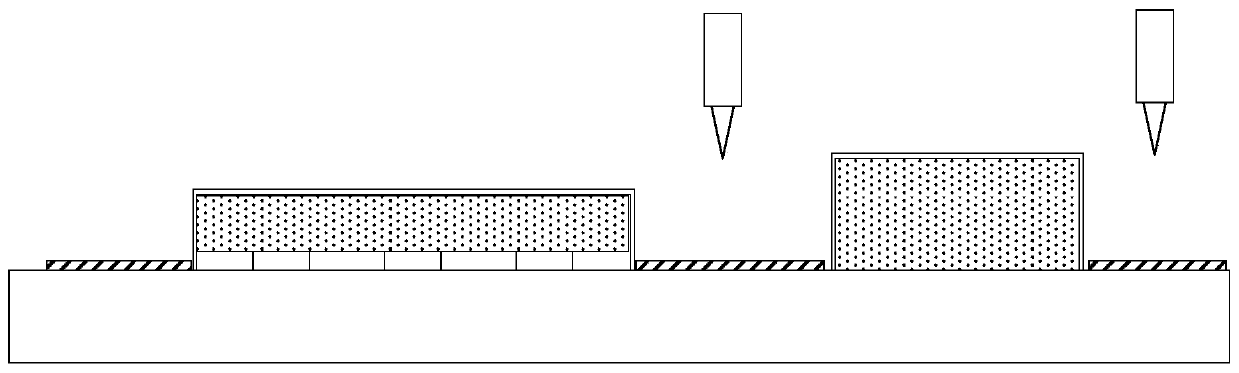

[0029] Step S3, using a laser to make grooves around the chips that need partition shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com