Manufacture process of high performance ductile iron roll

A manufacturing method and high-performance technology, applied in the field of crane drum and manufacturing, can solve technical difficulties and other problems, achieve huge economic benefits, improve utilization rate, and save processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

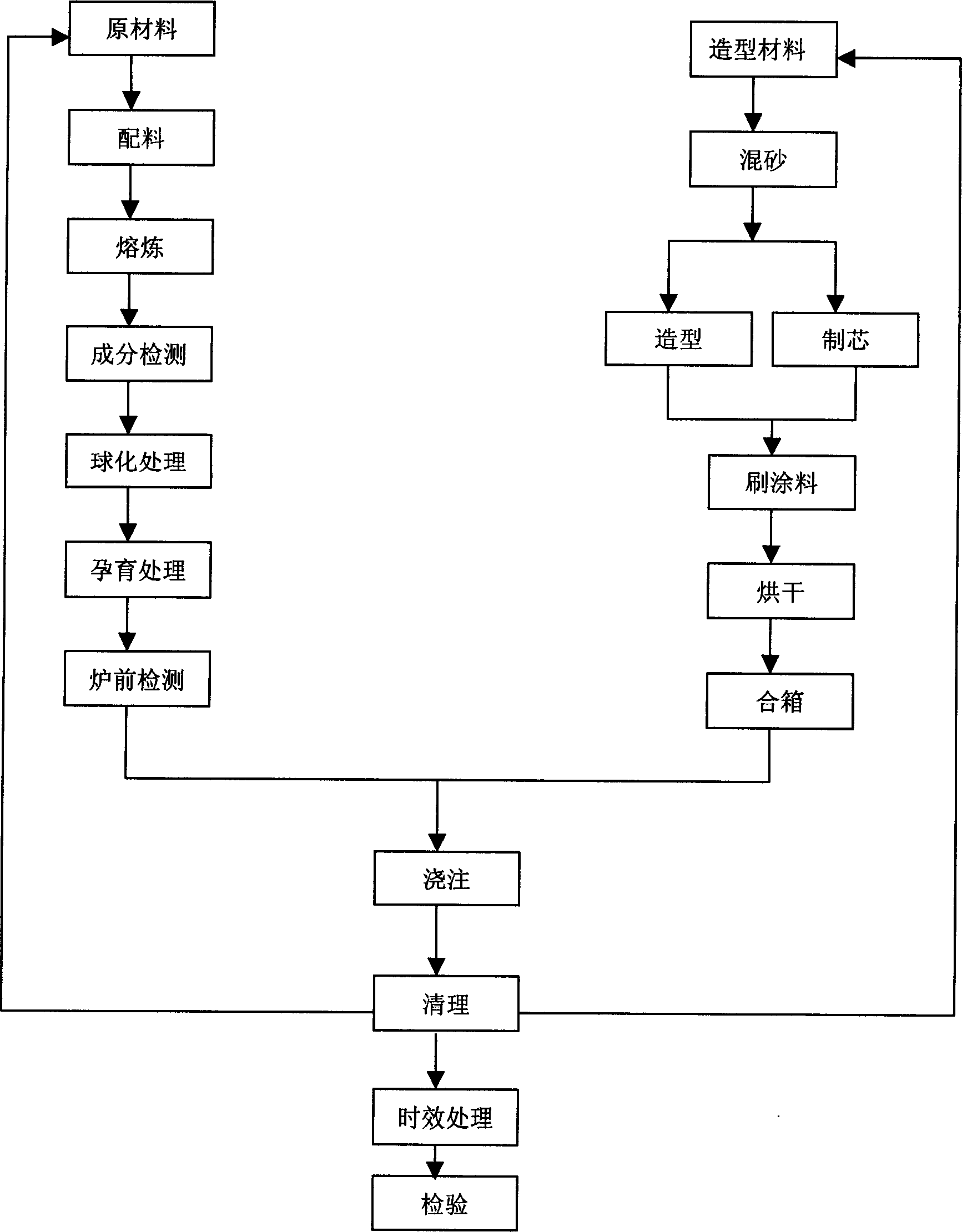

[0049] figure 1 Flow chart of the manufacturing process of ductile iron reel.

[0050] (1) Selection of mold material:

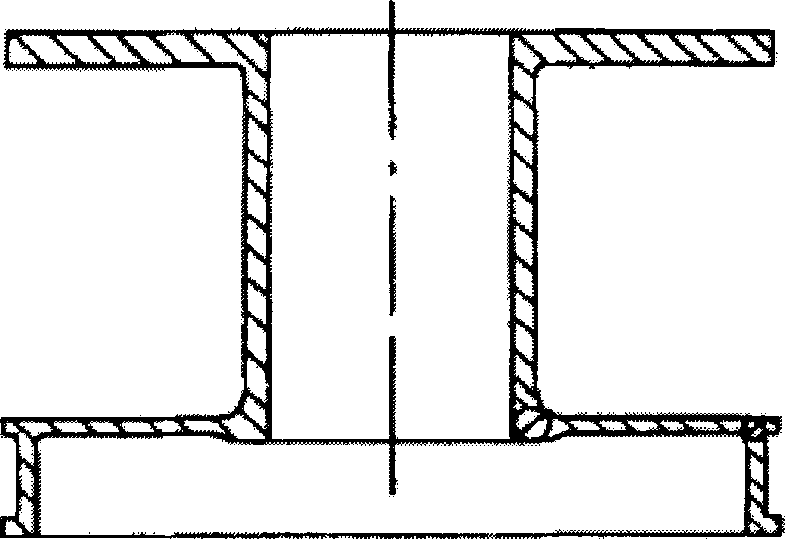

[0051] The mold material has a significant impact on the dimensional accuracy and defects of the casting. Since nodular iron is solidified in a paste state, it has a greater tendency to form shrinkage porosity, and shrinkage porosity significantly reduces the strength of the casting, so appropriate technological measures must be taken to eliminate it. The best method is to use the graphitization expansion during the solidification process for self-complementation. Shrinkage, which requires the mold to have a sufficiently high strength during solidification. Obviously, the green sand mold is difficult to meet this requirement, and due to the high moisture content, it is easy to react with the residual magnesium in the molten iron after spheroidizing treatment, resulting in subcutaneous pores, so it is not suitable for the production of nodular iron reels. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com