High-contrast-grating coupled-cavity narrow-spectral-line-width surface-emitting laser

A high-contrast grating and emitting laser technology, applied in the field of optoelectronics, can solve problems such as restricting the application of VCSELs, and achieve the effects of simplifying fabrication difficulty, improving yield and reliability, and simplifying design and fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

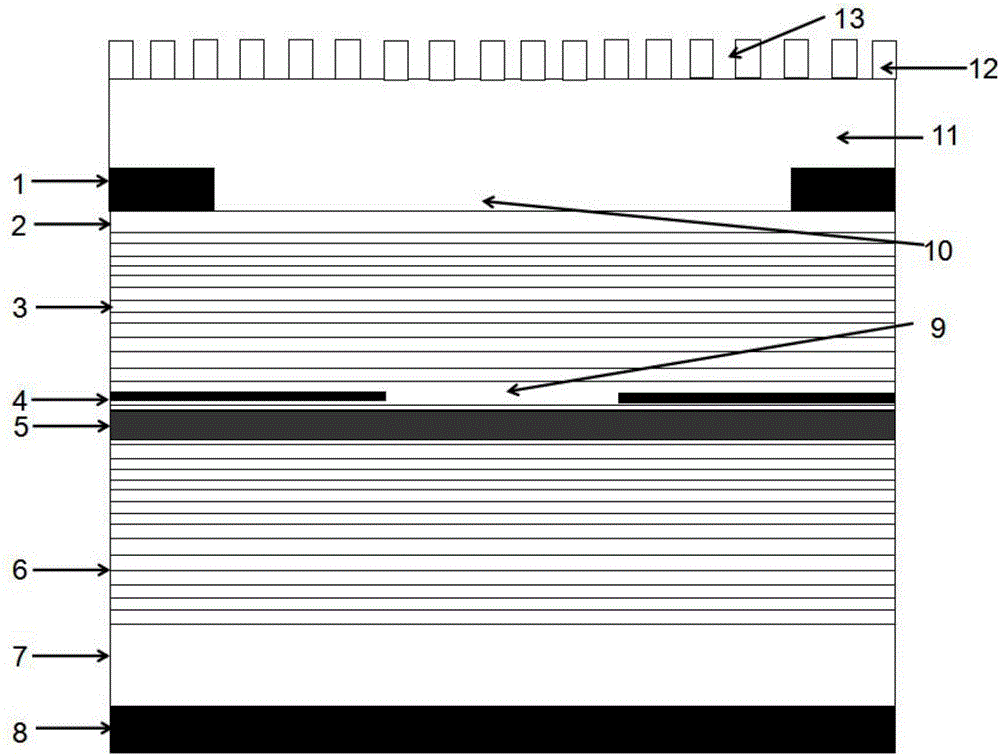

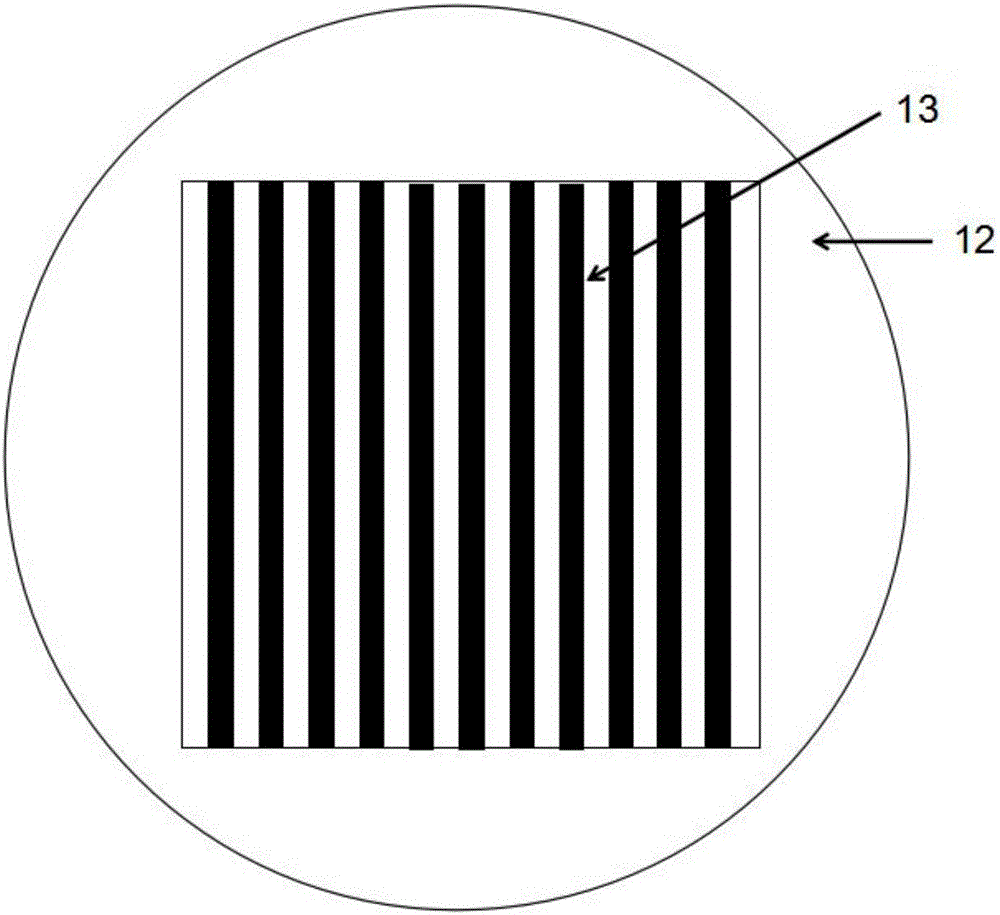

[0018] The following is attached Figure 1-2 And embodiment the present invention is described in further detail.

[0019] In order to achieve the above-mentioned purpose, the integrated high-contrast grating planar external cavity narrow-linewidth surface-emitting laser of the present invention adopts a brand-new physical idea, adopts epitaxial growth technology and semiconductor planar micro-nano processing technology, and carries out a brand-new design and production of the device . The device material is grown by MOCVD or MBE epitaxial growth technology, and the specific manufacturing process is as follows: grow lower DBR6, active region 5, Al 0.98 Ga 0.02Oxidation limiting layer of As high aluminum composition 4, upper distributed Bragg reflector (upper DBR) 3 with periodic alternate growth, P-type ohmic contact layer 2, upper metal electrode (P-type metal electrode) 1, N-type metal electrode 8 set At the bottom of the substrate 7, the oxidation hole 9 is set in the Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com