Overlapped and compressed type sealant hot runner system

A hot runner and compaction technology, which is applied in the field of superimposed compaction sealing hot runner system, can solve the problems of dead angle in the runner, difficult color change, rubber retention, etc., to reduce pressure drop, easy color change, The effect of glue removal is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

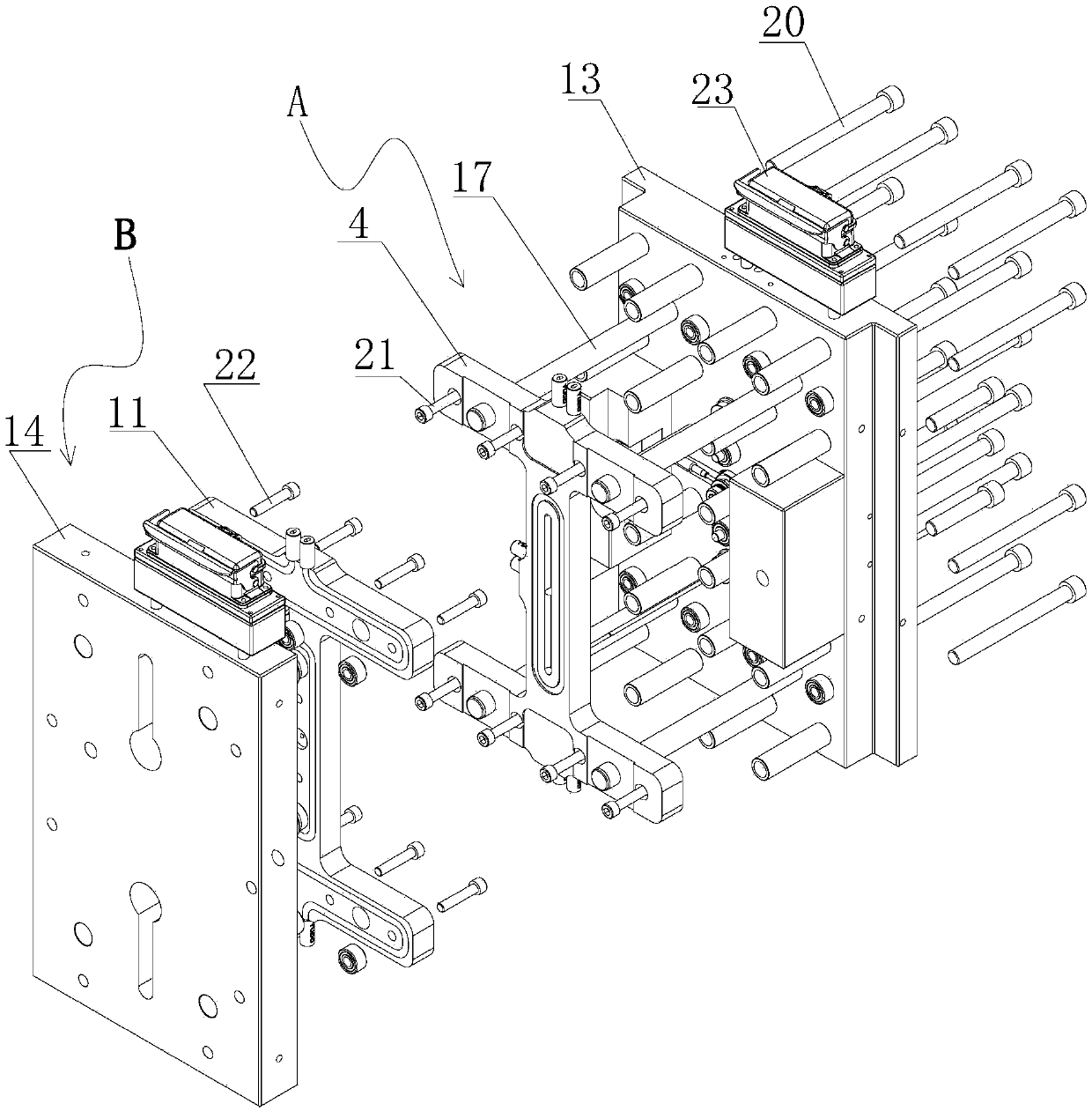

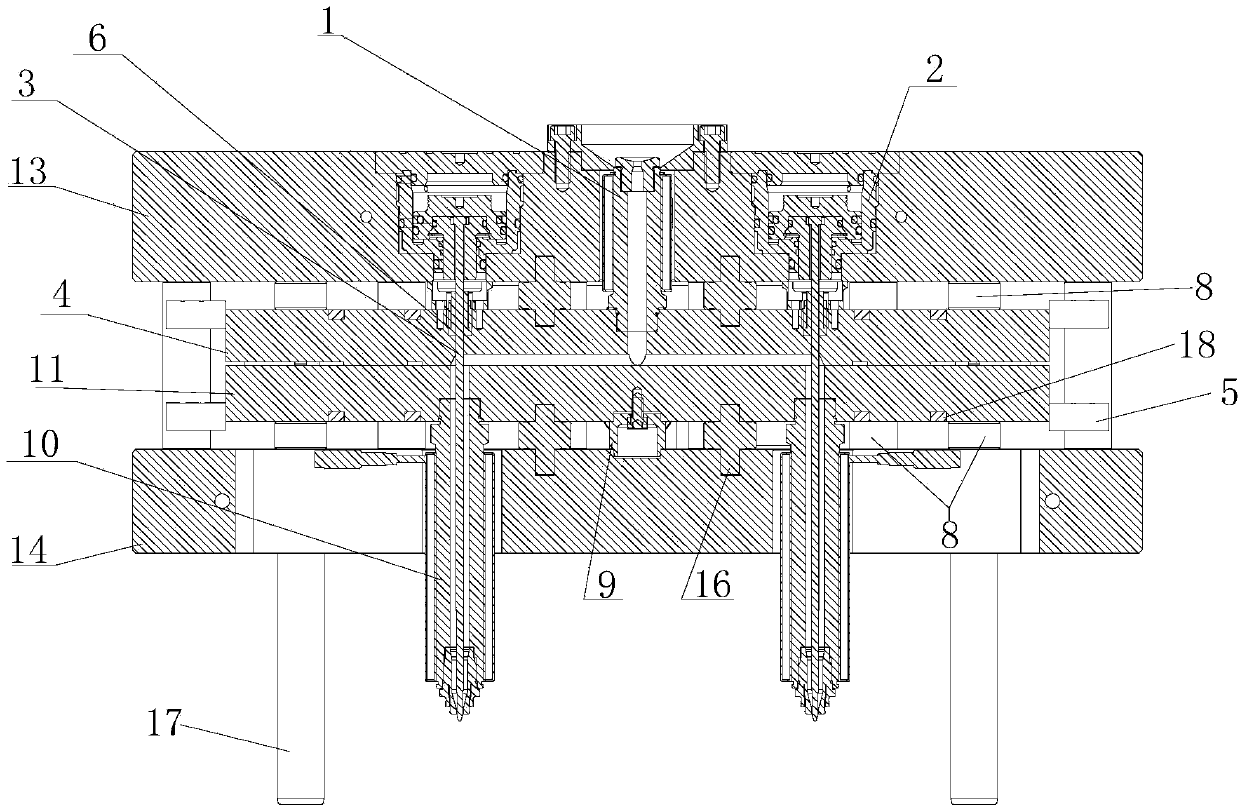

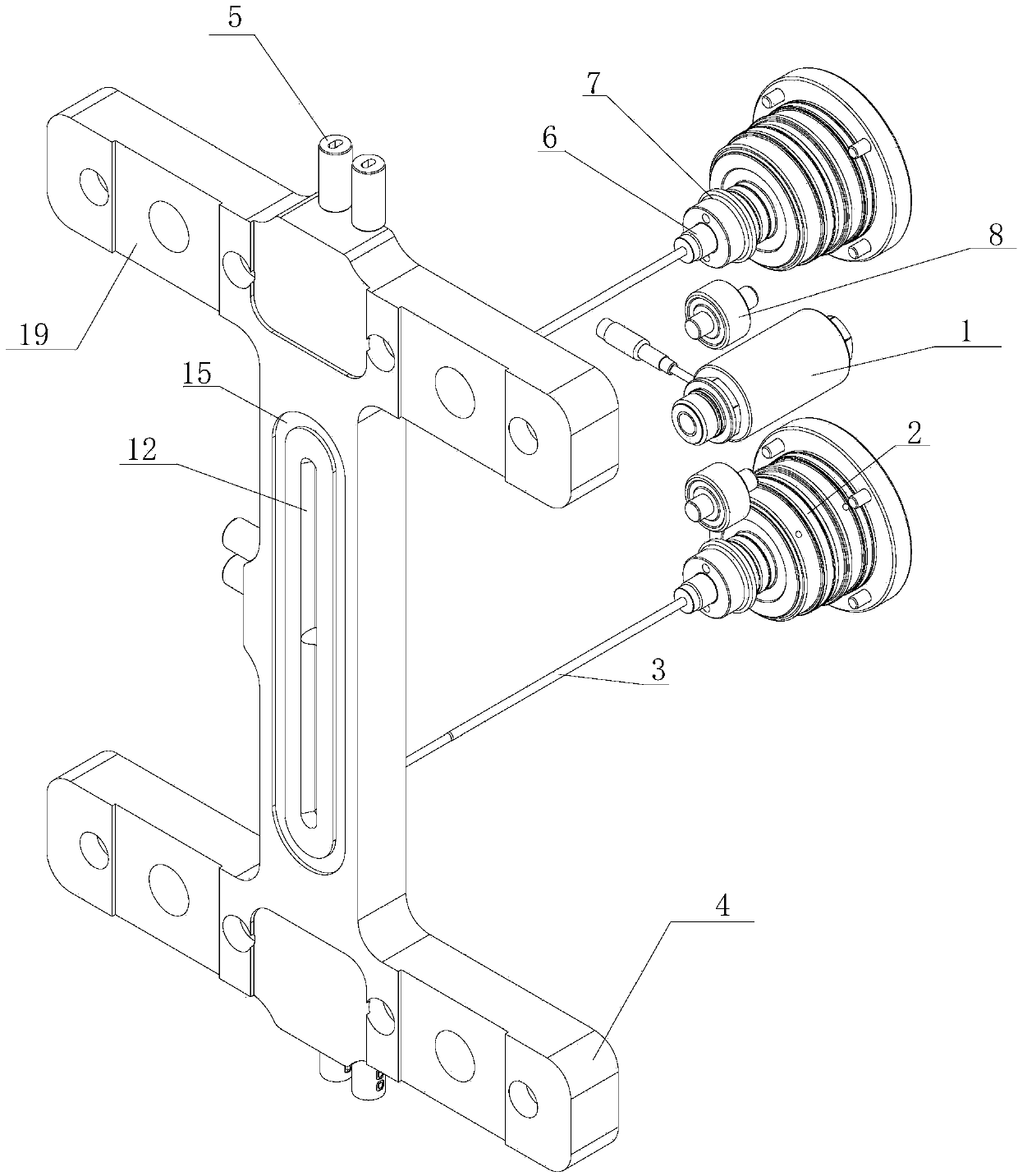

[0034] Example: superimposed compression sealing hot runner system

[0035] See attached figure 1 ~ attached Image 6 As shown, a superimposed compression type sealing hot runner system, the distribution plate of the superposition compression type sealing hot runner system is composed of two parts spliced, that is, the first plate 4 of the distribution plate and the second plate 11 of the distribution plate Superimposed splicing composition. And the flow channel 12 is formed on the surface of the first block 4 of the distribution plate. However, the flow channel in the prior art is formed inside a steel plate by gun drilling. Because the technical solution of the present invention opens the flow channel 12 on the surface of the first plate 4 of the distributor plate, the processing technology is simple, and the formed flow channel will not have dead angles, roughness and the like.

[0036] In order to overlap and splice together the first plate 4 of the manifold and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com