Silicon-heater-based MEMS (microelectromechanical system) methane sensor and preparation method and application thereof

A methane sensor and heater technology, applied in the direction of material resistance, etc., can solve the problems of difficult batch production, low sensitivity, poor consistency, etc., and achieve the effects of easy batch production, reduced raw material cost, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

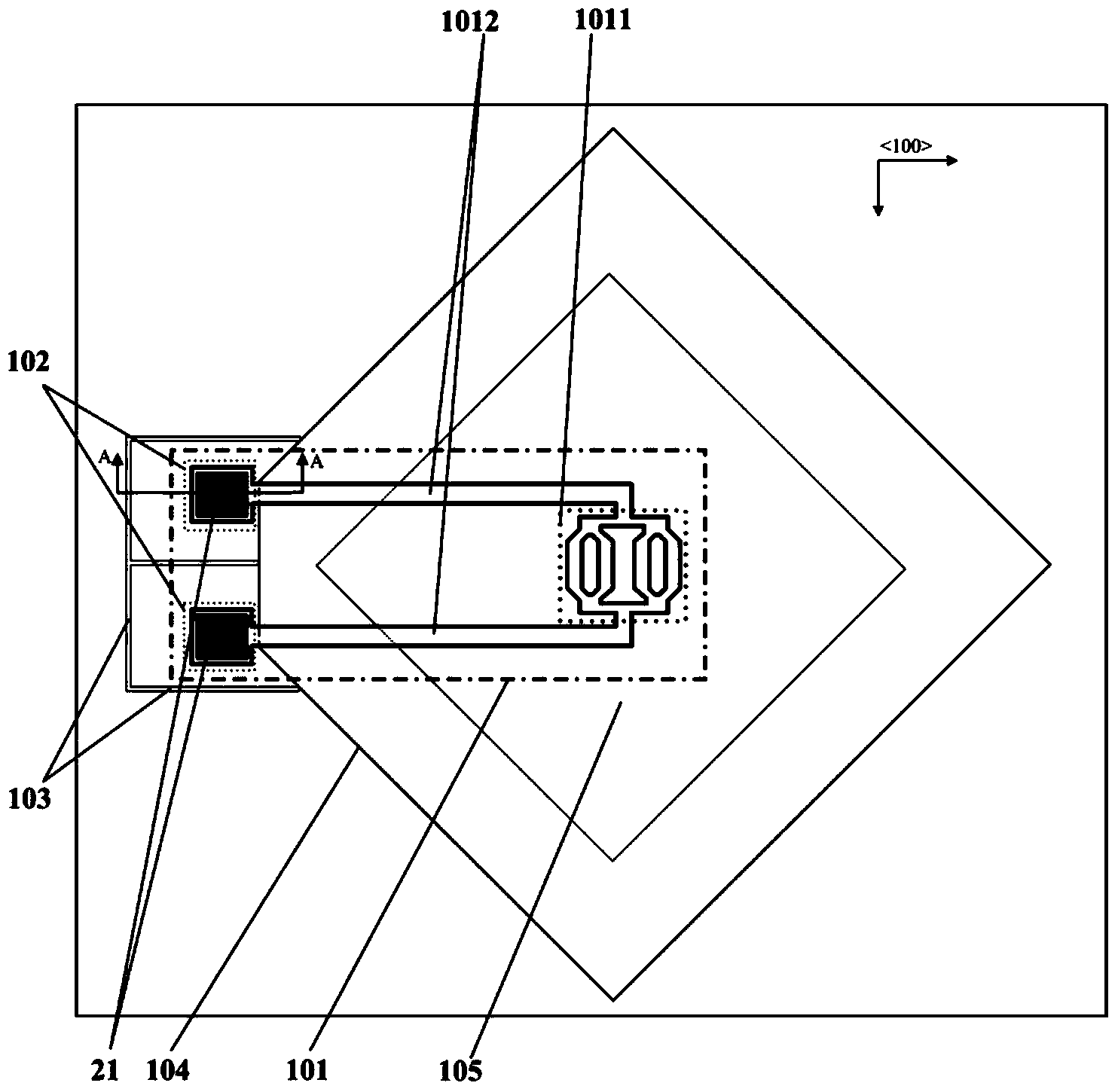

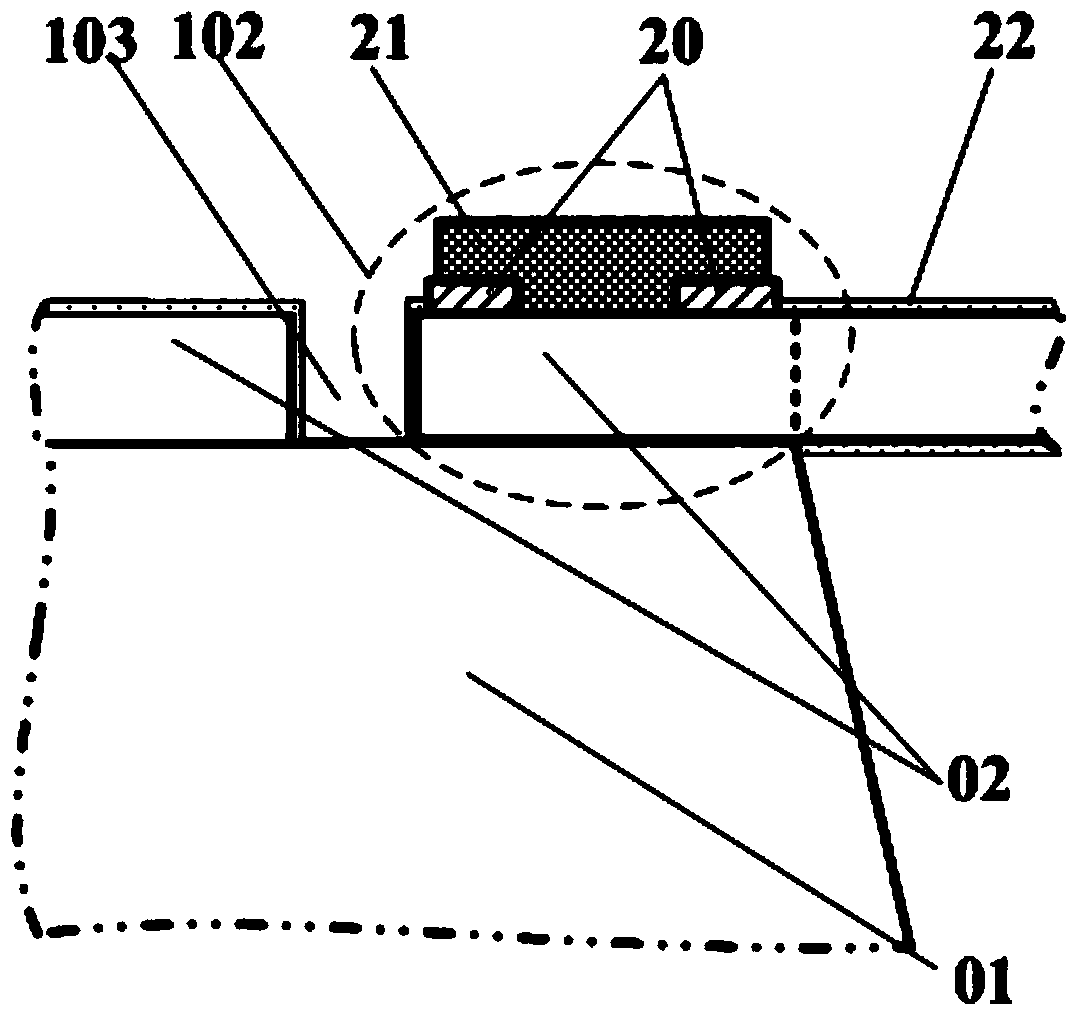

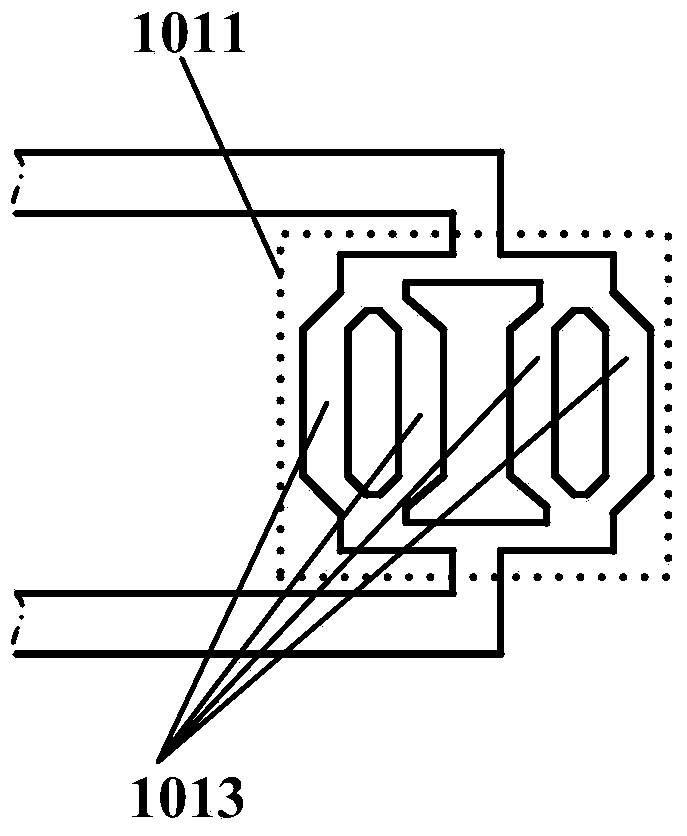

[0050] Example: in figure 1 , figure 2 , image 3 , Figure 4 Among them, the P-type silicon substrate 01 is used, and the P-type silicon substrate 01 is doped or diffused to form N-type silicon 02; the N-type silicon 02 on the P-type silicon substrate 01 is processed to prepare a silicon heating element 101; the silicon heating element 101 includes two fixed ends 102, a silicon heater 1011, and two silicon cantilevers 1012; the length of the single silicon cantilever 1012 is at least 300um; one end of the single silicon cantilever 1012 is connected to the silicon heater 1011, and the other end is connected to a fixed end 102 to provide electrical connection for the silicon heater 1011; the two silicon cantilevers 1012 are arranged in parallel and side by side, forming a U-shaped cantilever structure with the silicon heater 1011 as a whole, and the silicon heater 1011 is suspended In the air; the silicon heater 1011 of the silicon heating element 101 and the outer surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com