Schottky junction single-sided electrode crystalline silicon solar cell and preparation method thereof

A solar cell and Schottky junction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the light-receiving area of solar cells, reducing conversion efficiency, etc., achieving good light trapping effect, improving conversion efficiency, and increasing effective effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

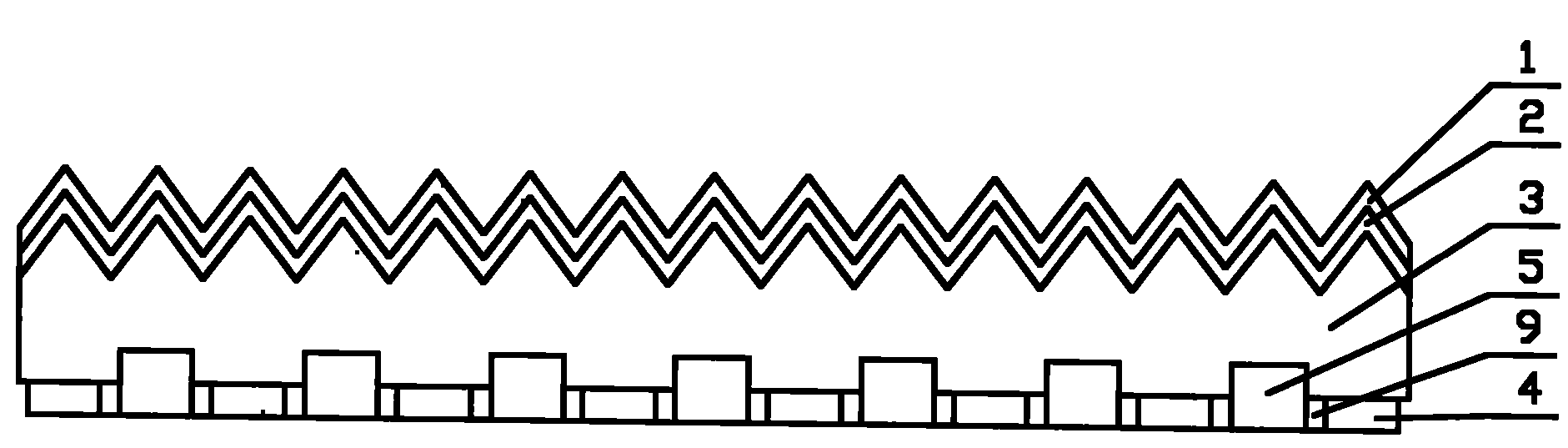

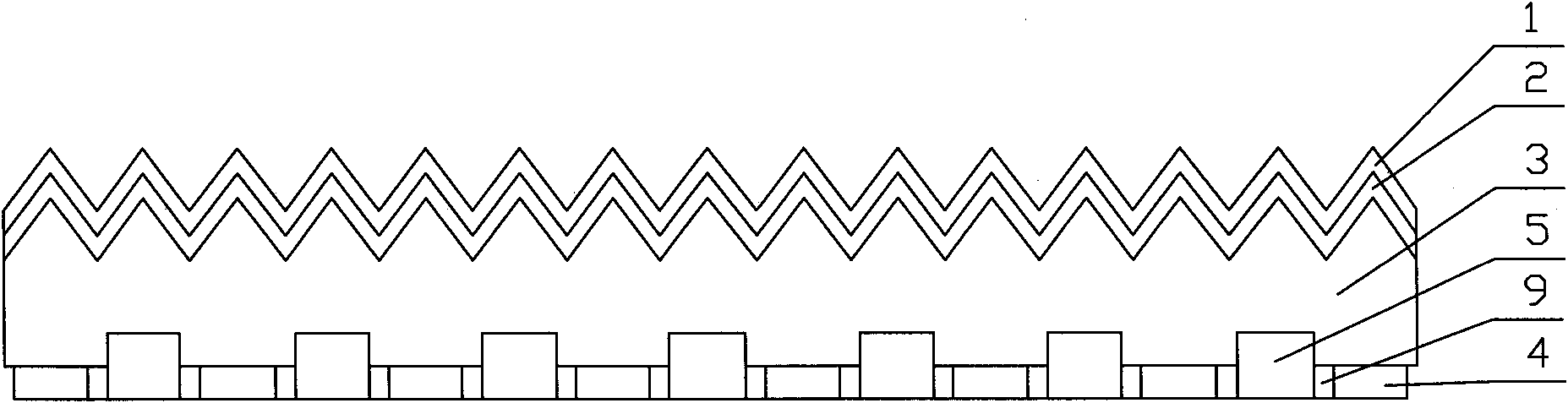

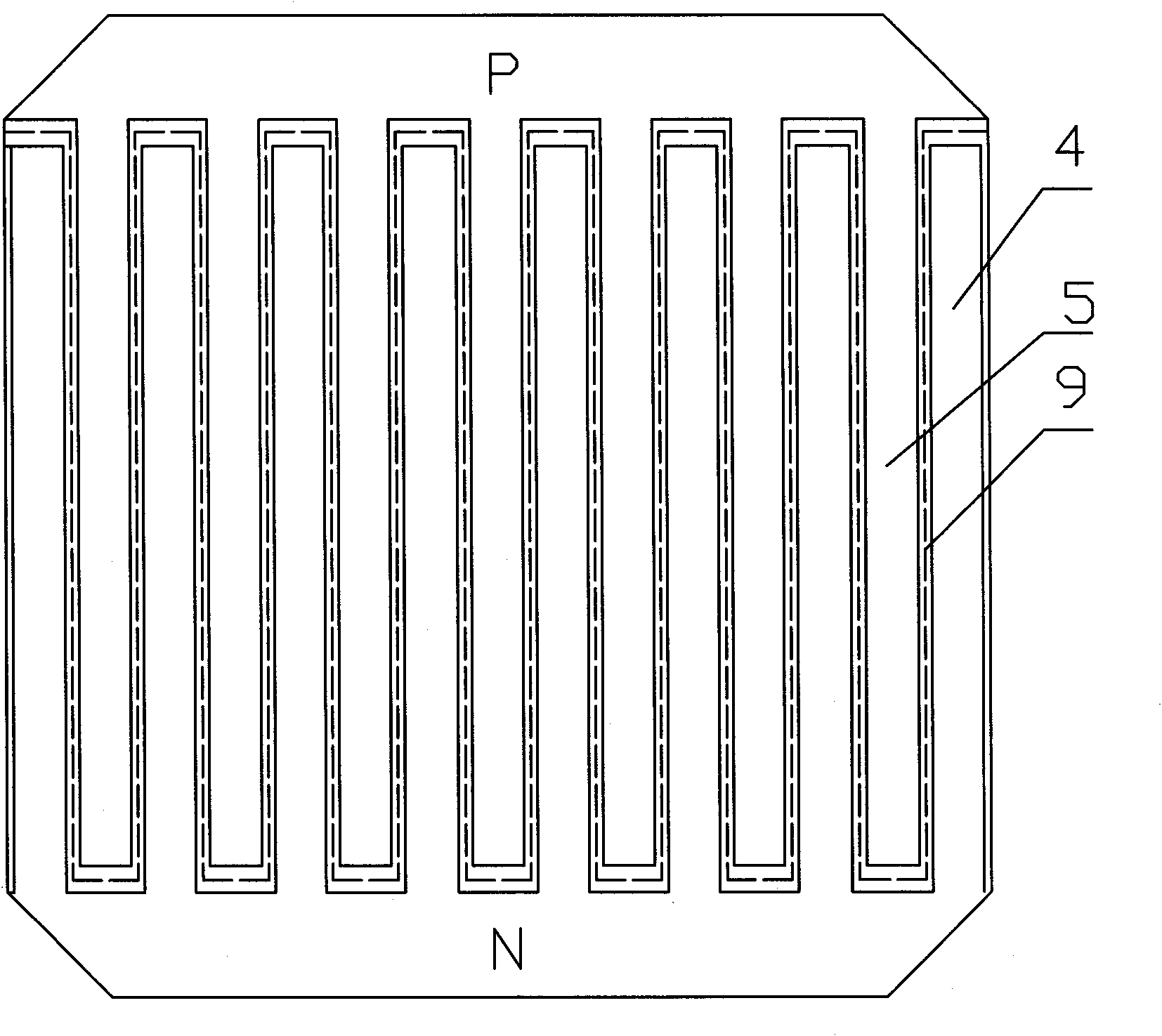

[0054] As shown in Figures 1 and 2, the selected crystal plane is 100 (the crystal plane of silicon is divided into 100, 110, and 111 according to the type, and each crystal plane has different physical and chemical properties), and the size is 156×156×180 μm The N-type substrate 3 has a textured structure on the light-receiving surface of the substrate, and a passivation layer 2 and an anti-reflection layer 1 are provided. Then set the grid-shaped aluminum negative electrode 5 on the backlight surface, the aluminum negative electrode 5 forms a Schottky grid junction with a certain depth with the crystalline silicon, and then set the grid-shaped silver-aluminum lead-out positive electrode 4 forming ohmic contact with the backlight surface at the remaining positions , There is a certain gap 9 between the positive electrode 4 and the aluminum negative electrode 5 .

Embodiment 2

[0056] As shown in Figures 3 and 4, select an N-type substrate 3 with a crystal plane of 100 and a size of 156×156×100 μm, make a textured structure on the light-receiving surface of the substrate, and set a passivation layer 2 and an anti-reflection layer 1. An N+ doped layer 8 is arranged on the backlight surface of the substrate, and then a grid-shaped aluminum layer 6 with a Schottky PN junction penetrating the N+ doped layer is arranged on the N+ doped layer, and then a grid-shaped silver-aluminum lead-out positive electrode is arranged on the remaining positions. There is a certain gap 9 between the electrode 7 , the positive electrode 7 and the grid-shaped aluminum layer 6 .

Embodiment 3

[0058] 1) Select an N-type substrate with a crystal plane of 100 and a size of 156×156×100 μm, and send it to a texturing equipment for routine cleaning and texturing to produce a textured surface with a refractive index of 2.2. 2) Plating a passivation layer and an anti-reflection layer on the suede surface of the light-receiving surface. 3) Screen-print grid-shaped aluminum paste on the backlight surface of the substrate with a grid width of 0.3 mm. 4) Selectively irradiate the position of the aluminum paste on the substrate with a continuous strong laser, so that the temperature of the substrate rises to 1400°C instantaneously, and continue to irradiate for 25 minutes. 5) Print grid-shaped silver-aluminum electrodes on other positions on the backlight surface. 6) Perform aluminum back field sintering to complete the solar cell preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com