Surface source black body and manufacturing method thereof

A technology of surface source blackbody and manufacturing method, which is applied in the field of blackbody, can solve the problems of lower emissivity and affect the performance of surface source blackbody radiation source, etc., and achieve the effects of simple production, saving processing technology and high emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

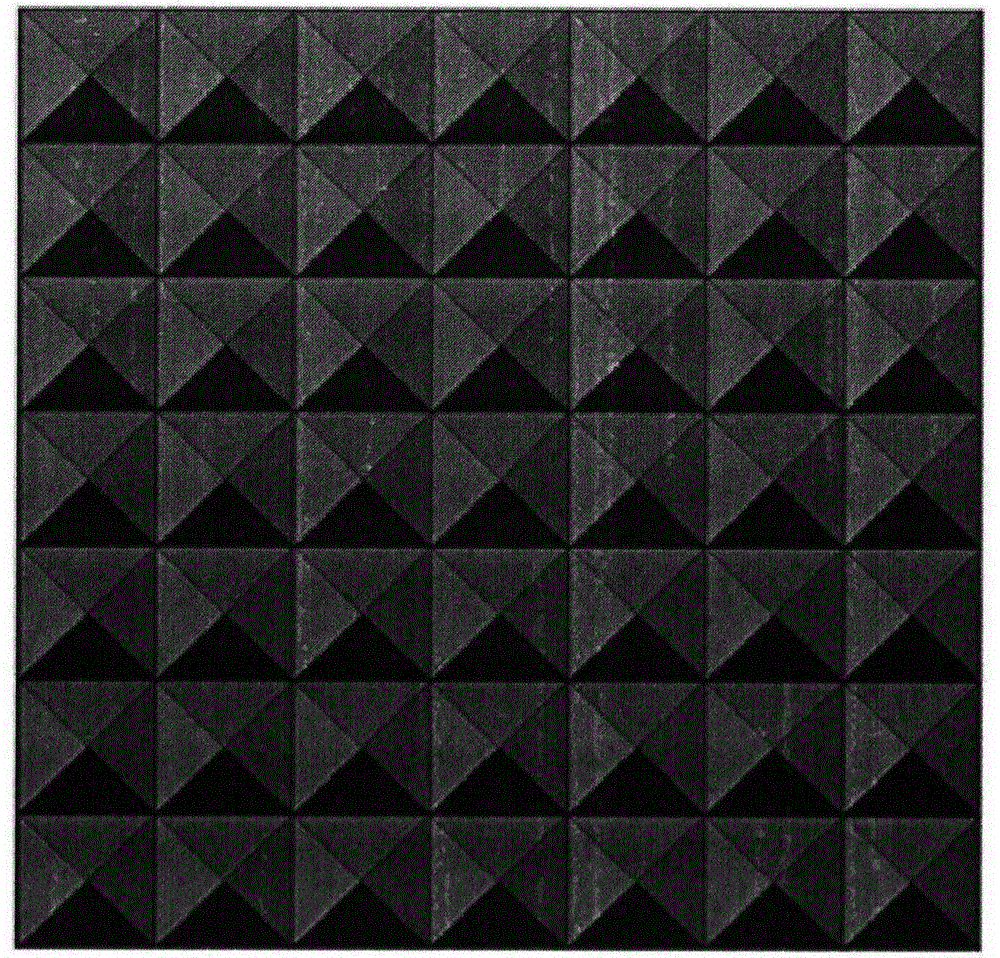

[0033] like figure 1 As shown, the top view structural schematic diagram of the surface source black body of the first embodiment of the present invention, from figure 1 It can be seen from the above that the surface source blackbody has a rectangular pyramid arranged in a matrix, and the surface source blackbody is a matrix combination of N rows and M columns, wherein N is an integer greater than 1, and M is also an integer greater than 1. When it is necessary to set a large-area surface source blackbody, set N and M to larger values, so as to obtain a large-sized surface source blackbody, and set different numbers of squares according to the size of the specific surface source blackbody. The cone can obtain surface source blackbodies of different sizes to meet the demand for surface source blackbodies of different calibers.

[0034] like figure 2 As shown, the schematic diagram of the bottom surface structure of the surface source black body of the first embodiment of the...

Embodiment 2

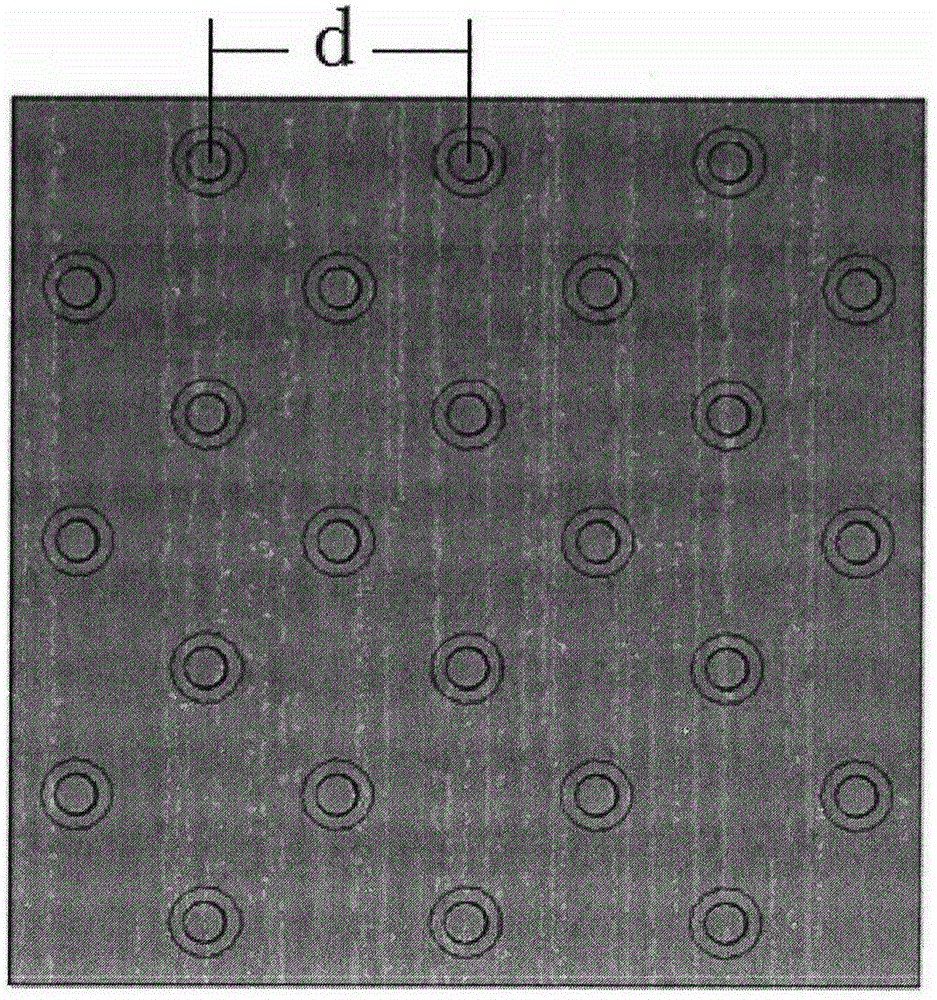

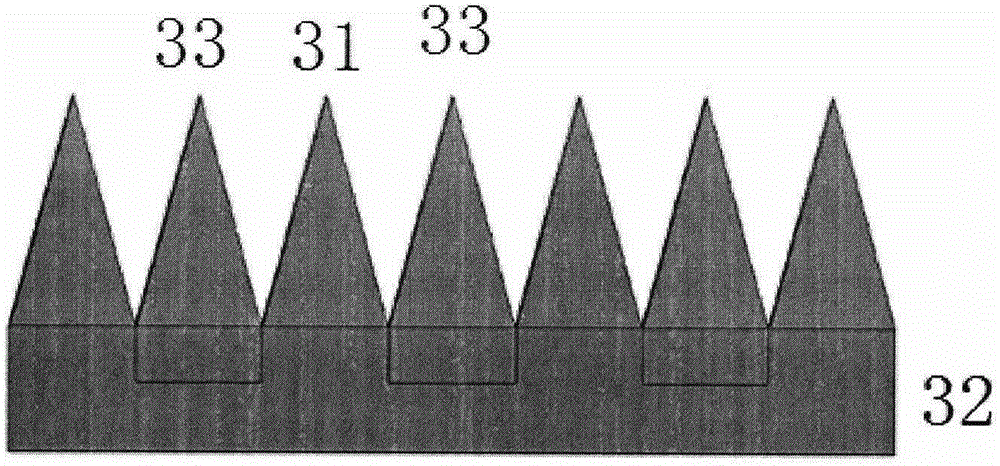

[0038] like Figure 8 Shown is a schematic top view of the surface source blackbody of the second embodiment of the present invention. The second embodiment is the same as the first embodiment, and the description will not be repeated. The surface source black body adopts a matrix structure of N rows and M columns. In a certain row, there is a distance d / 2 between any adjacent quadrangular pyramids , and in the same row, the four-sided pyramid and the holes on the bottom plate are distributed at intervals, the distance between any two adjacent holes is d, and in the previous or next row of the certain row, any adjacent The holes are arranged at a distance of d / 2. like Figure 9 As shown, from the bottom of the bottom plate, it is found that the holes on the bottom plate are arranged crosswise in the row direction and the column direction; Figure 10 It is a schematic diagram of the three-dimensional structure of the surface source blackbody of the second embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com