Whitening ultraviolet-proof cable insulating rubber and manufacturing method thereof

A cable insulation and anti-ultraviolet technology, which is applied in the manufacture of whitening and anti-ultraviolet cable insulating rubber, and in the field of whitening and anti-ultraviolet cable insulating rubber. and other problems, to achieve excellent resistance to sunlight and weathering aging, to ensure strength and process performance, and to accelerate the vulcanization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

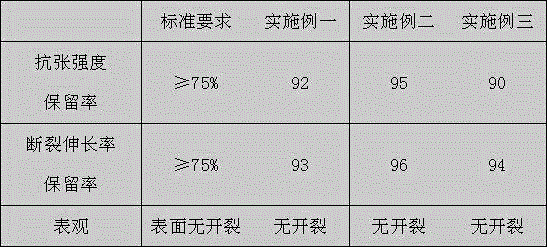

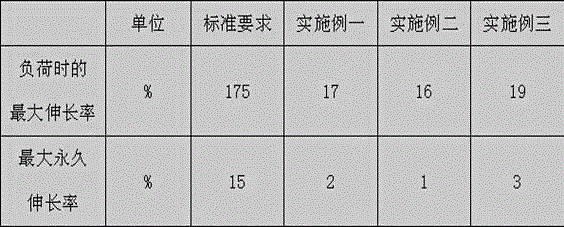

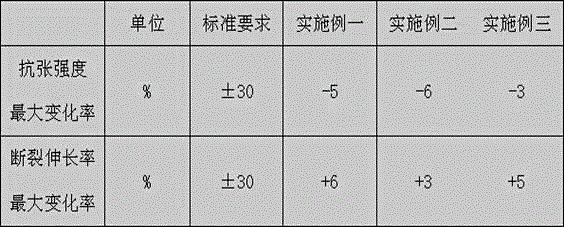

Embodiment 1

[0019] The preparation steps of whitening UV-resistant cable insulating rubber are as follows: (1) Prepare raw materials according to the following components and weight content, EPDM Keltan 5508: 12 parts; EPDM Keltan 21: 8 parts; vulcanization accelerator Triallyl isocyanurate: 0.4 parts; vulcanizing agent dicumyl peroxide: 0.5 parts; anti-aging agent 2-mercaptobenzimidazole: 0.3 parts; anti-aging agent 2,2'-methylenebis (4-methyl-6-tert-butylphenol): 0.1 part; active agent zinc oxide: 0.8 part; active agent stearic acid: 0.1 part; colorant rutile titanium dioxide: 1 part; filler active light carbonic acid Calcium: 10 parts; filler superfine talc powder: 10 parts; plasticizer 38# cylinder oil: 2 parts; reinforcing agent fumed silica: 2 parts; ultraviolet absorber 2-(2'-hydroxyl- 3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole: 0.05 parts; coupling agent γ-methacryloxypropyltrimethoxysilane: 0.1 parts; ( 2) First raise the temperature of the internal mixer to 60°C, add ...

Embodiment 2

[0022] The preparation steps of whitening UV-resistant cable insulating rubber are as follows: (1) Prepare raw materials according to the following components and weight content, EPDM Keltan 5508: 12 parts; EPDM Keltan 21: 8 parts; vulcanization accelerator Triallyl isocyanurate: 0.5 parts; Vulcanizing agent dicumyl peroxide: 0.6 parts; Antiaging agent 2-mercaptobenzimidazole: 0.5 parts; Antiaging agent 2,2'-methylenebis (4-methyl-6-tert-butylphenol): 0.15 parts; active agent zinc oxide: 1.0 parts; active agent stearic acid: 0.2 parts; colorant rutile titanium dioxide: 1.2 parts; filler active light carbonic acid Calcium: 11 parts; superfine talcum powder filler: 11 parts; plasticizer 38# cylinder oil: 2.5 parts; reinforcing agent fumed hydrated silica: 2.5 parts; ultraviolet absorber 2-(2'-hydroxy- 3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole: 0.08 parts; coupling agent γ-methacryloxypropyltrimethoxysilane: 0.2 parts; ( 2) First raise the temperature of the internal ...

Embodiment 3

[0025] The preparation steps of whitening UV-resistant cable insulating rubber are as follows: (1) Prepare raw materials according to the following components and weight content, EPDM Keltan 5508: 12 parts; EPDM Keltan 21: 8 parts; vulcanization accelerator Triallyl isocyanurate: 0.6 parts; Vulcanizing agent dicumyl peroxide: 0.8 parts; Antiaging agent 2-mercaptobenzimidazole: 0.6 parts; Antiaging agent 2,2'-methylenebis (4-methyl-6-tert-butylphenol): 0.2 parts; active agent zinc oxide: 1.2 parts; active agent stearic acid: 0.3 parts; colorant rutile titanium dioxide: 1.5 parts; filler active light carbonic acid Calcium: 12 parts; superfine talcum powder filler: 12 parts; plasticizer 38# cylinder oil: 3 parts; reinforcing agent fumed silica: 3 parts; ultraviolet absorber 2-(2'-hydroxyl- 3'-tert-butyl-5'-methylphenyl)-5-chlorobenzotriazole: 0.1 part; coupling agent γ-methacryloxypropyl trimethoxysilane: 0.3 part; ( 2) First raise the temperature of the internal mixer to 70°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com