Array substrate, preparation method thereof and liquid crystal display panel

A technology of array substrates and substrates, which is applied in semiconductor/solid-state device manufacturing, instruments, semiconductor devices, etc., can solve the problems of high cost, complex preparation process, high thickness of display panel, etc., achieve thickness reduction, save process technology, and reduce product cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

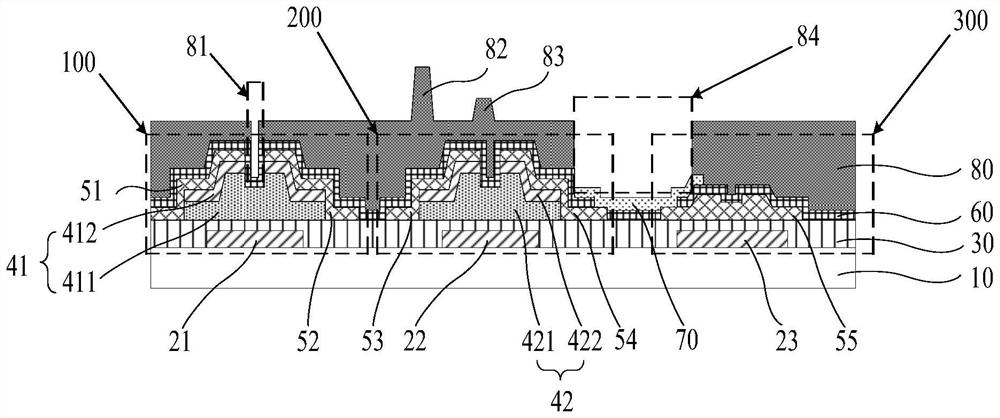

[0041] see figure 1 , a schematic structural diagram of the array substrate provided in the embodiment of the present application.

[0042] In this embodiment, the array substrate includes a substrate 10; a display thin film transistor 200, the array of display thin film transistors 200 is arranged on the substrate 10; a photosensitive thin film transistor 100, and the photosensitive thin film transistor 100 is arranged on the On the substrate 10 ; wherein, the display thin film transistor 200 and the photosensitive thin film transistor 100 are arranged in the same layer and spaced apart.

[0043] The array substrate further includes a first metal layer, a first insulating layer 30 , a semiconductor layer, a second metal layer, a second insulating layer 60 and a transparent electrode 70 stacked on the substrate 10 in sequence.

[0044] In this embodiment, the substrate 10 is a PI substrate, mainly polyimide, and the PI material can effectively improve light transmittance.

...

Embodiment 2

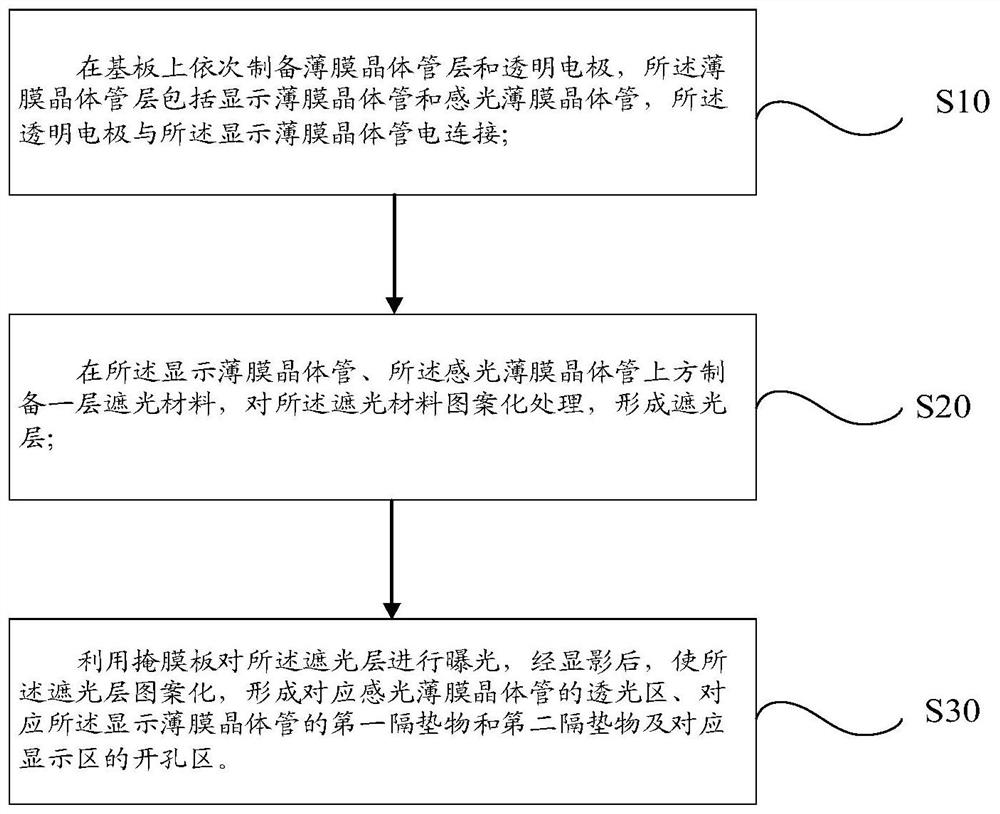

[0059] see figure 2 , a flow chart of the steps of the method for preparing the array substrate provided in the embodiment of the present application.

[0060] In this embodiment, the preparation method of the array substrate includes:

[0061] Step S10: sequentially prepare a thin film transistor layer and a transparent electrode 70 on the substrate 10, the thin film transistor layer includes a display thin film transistor 200 and a photosensitive thin film transistor 100, and the transparent electrode 70 is electrically connected to the display thin film transistor 100.

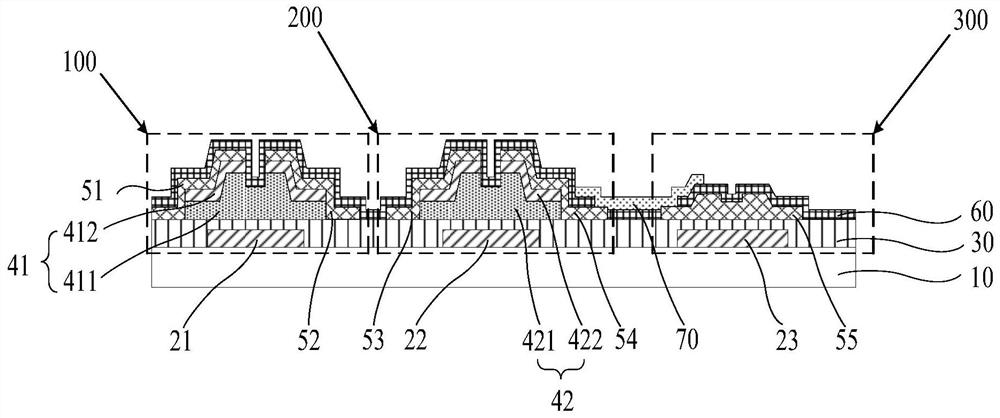

[0062] The step S10 also includes preparing a storage capacitor 300 on the substrate 10; the photosensitive thin film transistor 100, the display thin film transistor 200 and the storage capacitor 300 are arranged on the same layer and at intervals, as Figure 3A shown.

[0063] In said step S10, also include:

[0064] Step S11 : forming a first metal layer on the substrate 10 , the first metal layer in...

Embodiment 3

[0076] see Figure 4 , a schematic structural diagram of a liquid crystal display panel provided in an embodiment of the present application.

[0077] In this embodiment, the liquid crystal display panel includes the array substrate described in Embodiment 1, the color filter substrate 1000 and the liquid crystal layer 2000 located between the array substrate and the color filter substrate 1000 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com