High-accuracy positioning device of cutter working platform of numerical control lathe under fast operation

A technology of CNC lathes and positioning devices, which is used in manufacturing tools, large fixed members, metal processing equipment, etc., can solve problems such as poor positioning, and achieve the effect of ensuring consistency, ensuring processing dimensional accuracy, and reducing impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

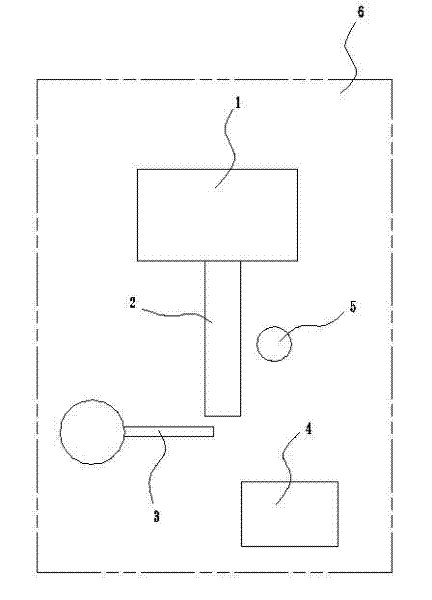

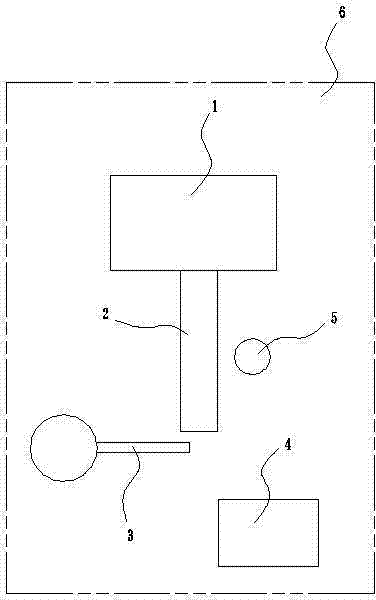

[0008] like figure 1 As shown, the present invention is a high-precision positioning device under the rapid operation of the CNC lathe tool table, including the tool table 1 arranged on the CNC lathe 6, and the front end of the tool table 1 is provided with an adjustable length contact rod 2. The left front side of the touch rod 2 is provided with a position-adjustable mechanical flow regulating valve for adjusting the hydraulic drive oil circuit of the tool table 1. 3. The right front side is provided with an adjustable limit switch 4. The lower right side is provided with Position-adjustable limit block 5; when the tool on the tool table 1 is close to the material to be processed, the contact rod 2 is in contact with the mechanical flow regulating valve 3. This position has been adjusted during adjustment, and the tool table 1 The hydraulic drive oil circuit is closed by the mechanical flow regulating valve 3, the speed of the tool table 1 is slowed down, and the forward imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com