Inner cavity groove and plane detection centering device

A hook groove and plane technology, which is applied in the field of inner cavity hook groove and plane detection and centering device, can solve the problem of affecting the gap between the compound ring air seal and the turbine rotor, affecting the installation accuracy of the compound ring on the turbine cylinder, and no products found To improve the efficiency of processing and inspection, reduce re-centering and repair, and reduce unqualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

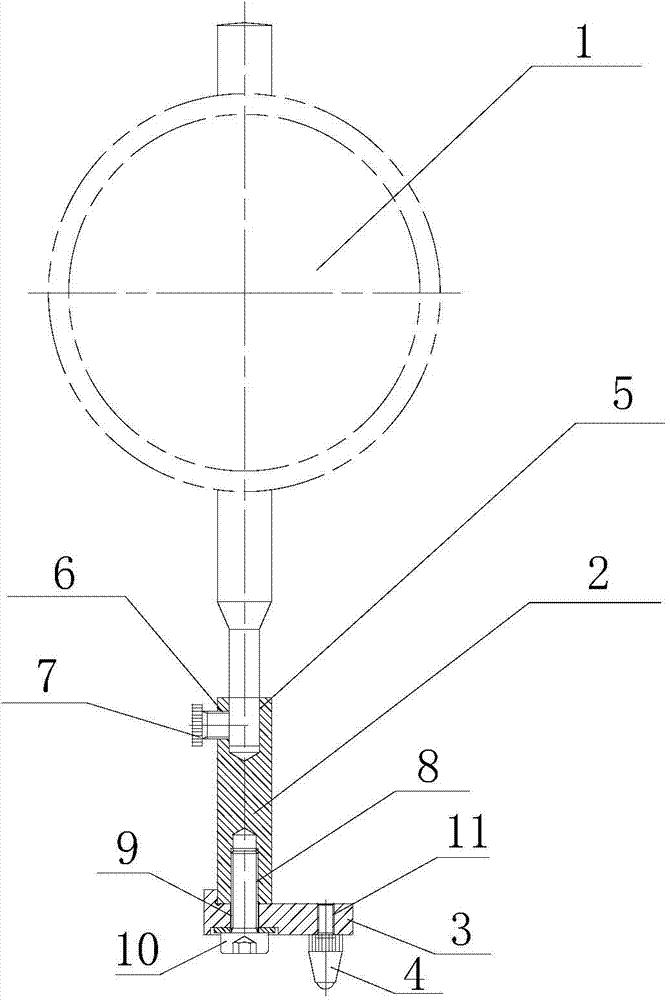

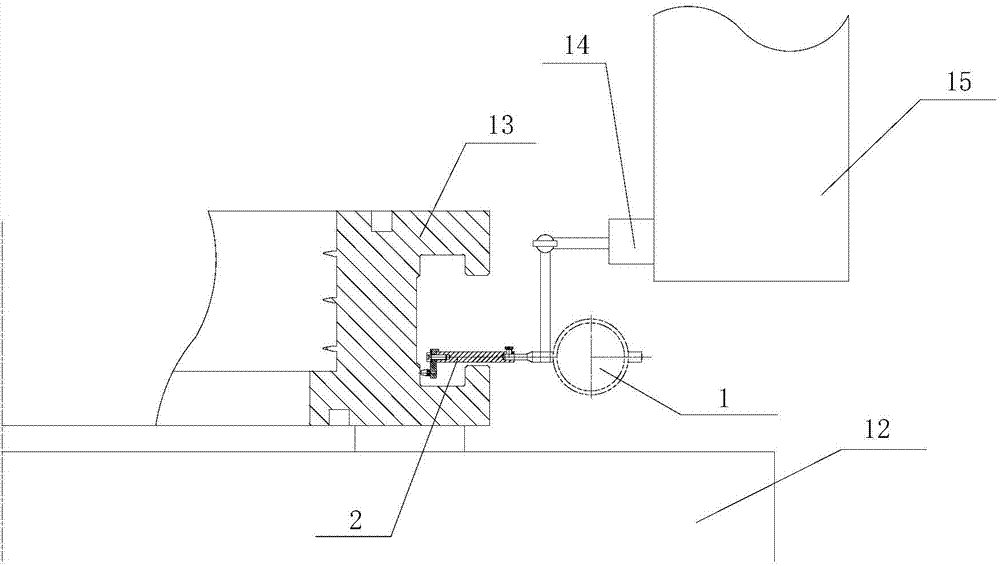

[0023] Such as figure 1 The inner cavity hook groove and plane detection and centering device shown include a dial indicator 1, a connecting support 2 and a contact connecting plate 3. One end of the connecting support 2 is connected to the detection rod of the dial indicator 1, and the other end is connected to the contactor connecting plate 3. One end of the head connection plate 3 is connected, the one end connected to the connection support 2 and the contact connection plate 3 is vertical, and the other end of the contact connection plate 3 is provided with a contact 4, and the contact connection plate 3 is "one" The contact 4 is perpendicular to the contact connecting plate 3, and the contact 4 and the connecting support 2 are arranged on both sides of the contact connecting plate 3 respectively.

[0024] The connection mode of described connecting support 2 and the measuring rod of dial indicator 1 is: the end that connecting supporting 2 is connected with the measuring ...

Embodiment 2

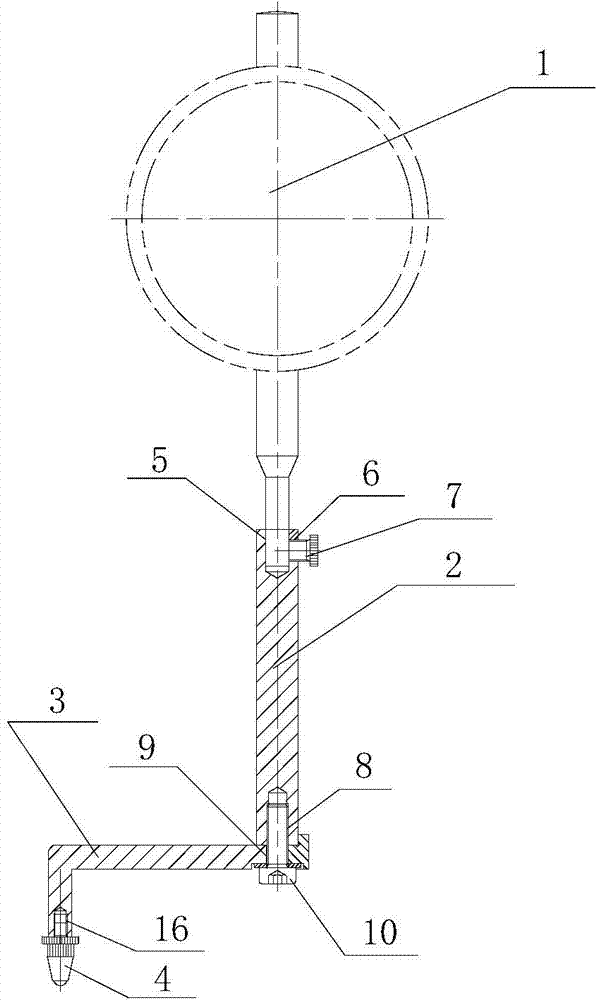

[0029] Such as image 3 The inner cavity hook groove and plane detection and centering device shown include a dial indicator 1, a connecting support 2 and a contact connecting plate 3. One end of the connecting support 2 is connected to the detection rod of the dial indicator 1, and the other end is connected to the contactor connecting plate 3. One end of the head connecting plate 3 is connected, the one end connected to the connecting support 2 and the contact connecting plate 3 is vertical, the other end of the contact connecting plate 3 is provided with a contact 4, and the contact connecting plate 3 is in the shape of "L" One end of the contact connecting plate 3 connected to the contact 4 is in line with the contact 4, and the contact 4 and the connecting support 2 are arranged on both sides of the contact connecting plate 3 respectively.

[0030] The connection mode of described connecting support 2 and the measuring rod of dial indicator 1 is: the end that connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com