A method for fabricating a cloth-based microfluidic chip based on ultraviolet lithography

A microfluidic chip and ultraviolet light technology, which is applied in the field of analysis and detection, can solve problems such as high complexity, low manufacturing precision, and difficult high-throughput detection, and achieve the effects of improved resolution, stable performance, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

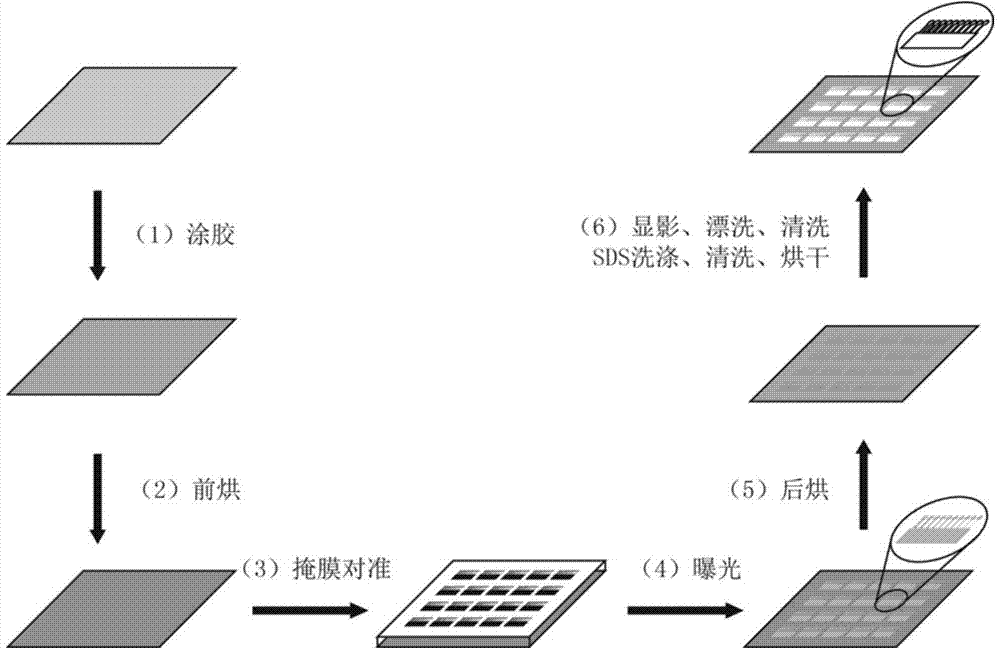

[0046] A method for preparing a cloth-based microfluidic chip based on ultraviolet lithography technology, comprising the steps of:

[0047] (1) Preparation of polyvinyl alcohol cinnamate (PVC) photoresist

[0048] Dissolve 15% PVC in 84.7% cyclohexanone, stir well, then add 0.3% 5-nitroacenaphthene, stir well to obtain polyvinyl alcohol cinnamate photoresist (PVC photoresist), transfer to brown bottle Among them, place it away from light for use; the percentage mentioned is the percentage of each raw material accounting for the total mass of the photoresist raw material;

[0049] (2) Fabrication of cloth-based microfluidic chips

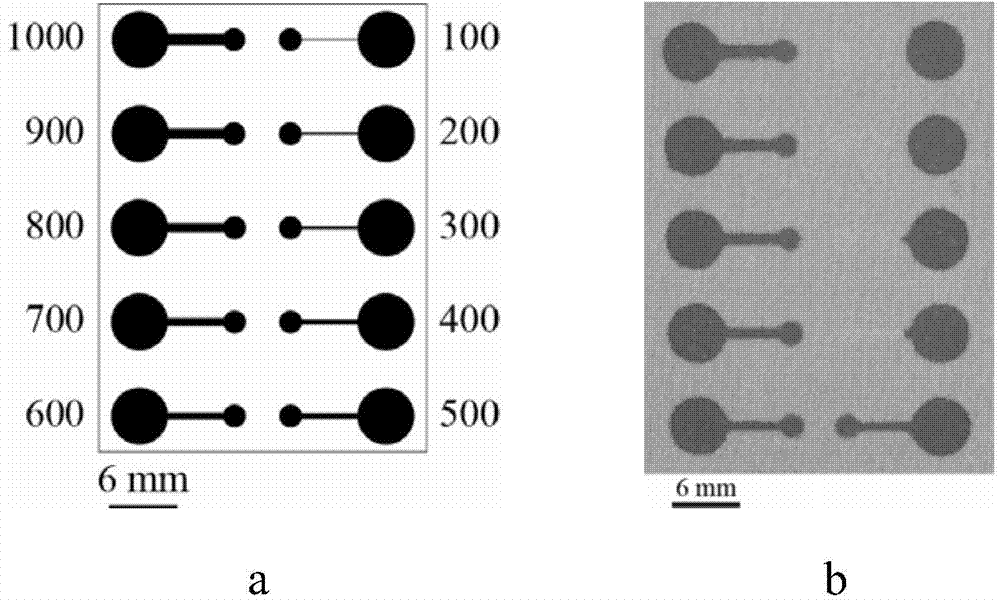

[0050] (a) Mask production: use Adobe Illustrator CS4 software to design the mask pattern of the microchannel width resolution of the cloth-based microfluidic chip (such as figure 2 As shown in a), the black part is the light-shielding part (corresponding to the hydrophilic region on the cloth-based microfluidic chip), and the white part is the l...

Embodiment 2

[0066] A method for fabricating a cloth-based microfluidic chip based on ultraviolet lithography technology, except for the following special instructions, other steps and materials are the same as in Example 1.

[0067] During the preparation process, several dike widths are set on the same cloth-based microfluidic chip to study its resolution. The design is as follows: image 3 For the mask shown in a, the black part corresponds to the hydrophilic region on the bucky microfluidic chip, and the white part corresponds to the hydrophobic region on the bucky microfluidic chip. image 3 The text below a indicates the width of the corresponding row of dams.

[0068] For the hydrophobic region, the width of all outer white square rings is 300 microns, while the width of the inner white square rings (ie, the width of the hydrophobic dam) is 100, 200, 300, 400, 500 and 600 microns from left to right.

[0069] image 3 b is the physical map of the cloth-based microfluidic chip processe...

Embodiment 3

[0071] A method for fabricating a cloth-based microfluidic chip based on ultraviolet lithography technology, except for the following special instructions, other steps and materials are the same as in Example 1.

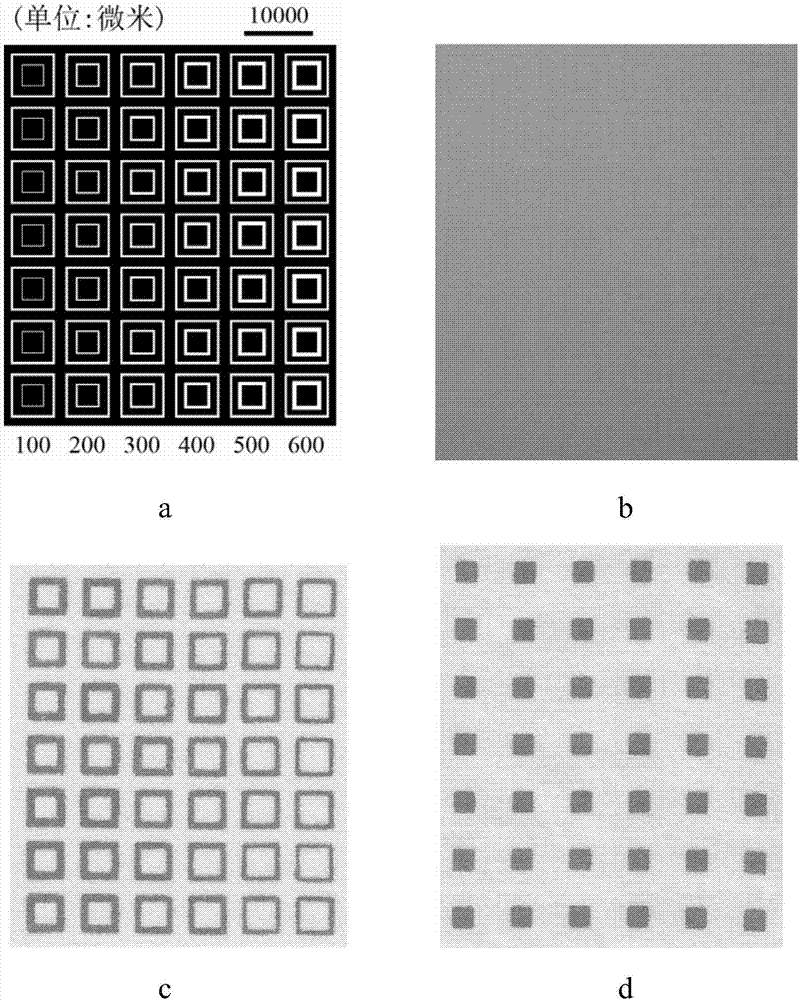

[0072] During the preparation process, an array of circular reaction cells (such as Figure 4 As shown in a, the reaction pool is the hydrophilic area, and the detection area and the sample injection area are the same reaction pool) for high-throughput glucose detection, and the diameter of each pool is 3 mm.

[0073] The glucose detection process is as follows: firstly, add 0.3 mol / L trehalose and 0.6 mol / L potassium iodide mixed solution into the array reaction cell, and dry at room temperature for 10 minutes; then add glucose oxidase solution and horseradish hydrogen peroxide with a volume ratio of 5:1 Enzyme solution (glucose oxidase activity is 120 units / ml, horseradish catalase activity is 30 units / liter), and dried at room temperature for 10 minutes to complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com