Quick make-up screw thread structure for expansion pipe under large expansion rate and its processing and preparation method

A technology of expansion pipe and expansion rate, which is applied in the field of quick make-up thread structure and processing and preparation for expansion pipe under large expansion rate, can solve the problem of not meeting the needs of emergency accidents and workover, restricting the development and application of expansion pipe technology, and sealing The problem of low pressure, etc., can improve the processing and inspection efficiency, improve the anti-galling performance, and prevent the failure of the thread seal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

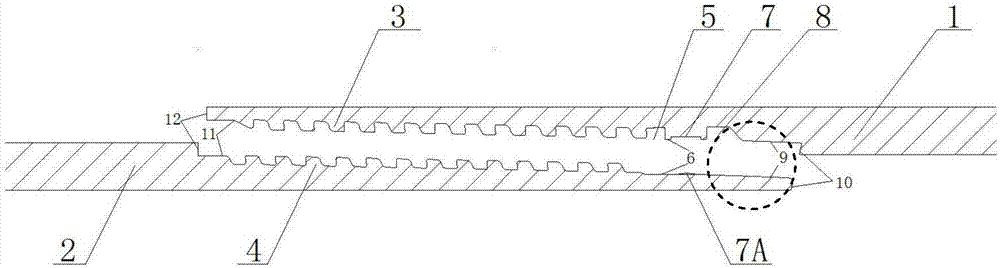

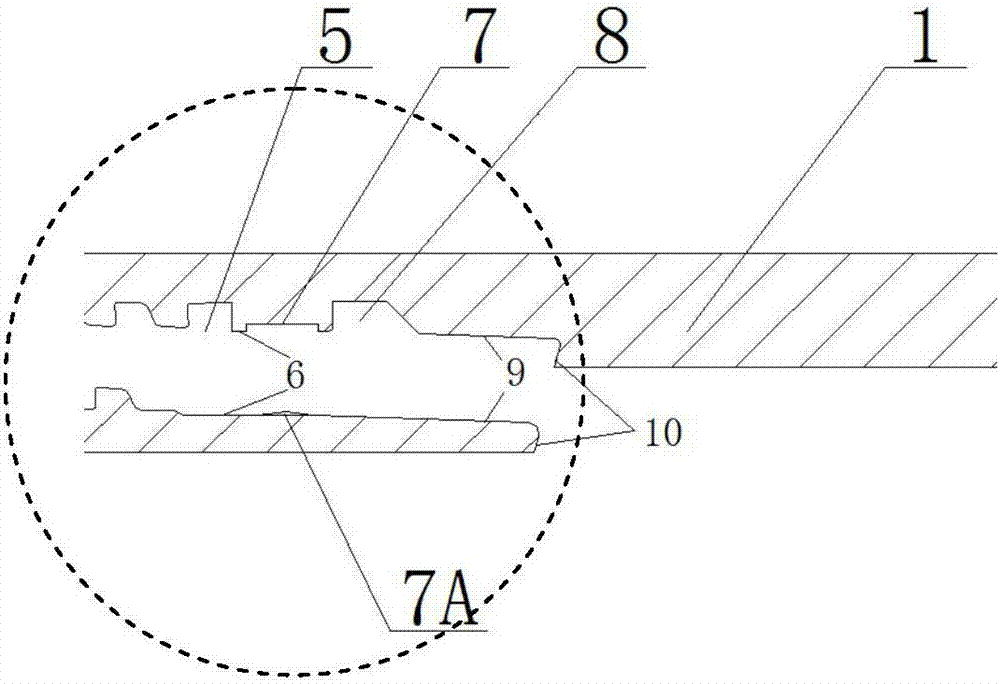

[0064] Example 1: A 140mm×8mm solid expansion pipe threaded joint that can expand by 28%

[0065] A 140mm×8mm solid expansion pipe body is used to process the threaded joint of the present invention, and the specific parameters are shown in Table 2.

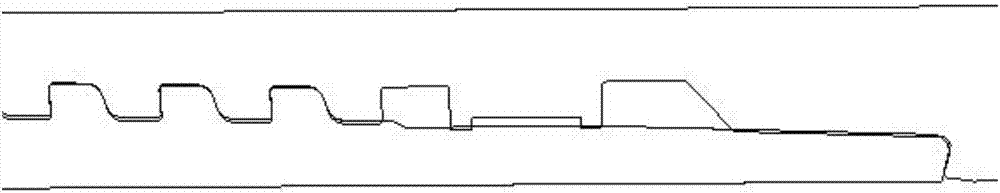

[0066] CNC machine tools are used to process the thread. When machining the box, first use the rough turning blade to process the end shoulder 12, the overall threaded cone surface, the cylinder-to-cylindrical sealing section 6, the cone-to-cone sealing section 9 and the negative angle Torque shoulder 10, the angle of the overall thread taper is the same as the thread taper, leaving 0.2mm for finishing when the rough machining cylinder faces the cylinder sealing section 6, the cone faces the cone sealing section 9 and the negative angle torque shoulder 10 Then use the fine turning blade to process the sealing section 6 of the cylinder facing the cylinder, the sealing section 9 of the cone facing the cone and the negative angle to...

Embodiment 2

[0074] Embodiment 2: 20% expandable 245mm×12mm solid expansion pipe threaded joint

[0075] A 245mm×12mm solid expansion pipe body is used to process the threaded joint of the present invention, and the specific parameters are shown in Table 3.

[0076] Use a CNC machine tool to process the thread. When machining the box, first use a rough turning blade to process the end shoulder 12, the overall thread cone surface, the cylinder-to-cylindrical sealing section 6, the cone-to-cone sealing section 9 and the negative angle Torque shoulder 10, the angle of the overall thread taper is the same as the thread taper, leaving 0.1mm for finishing machining when the rough machining cylinder faces the cylinder sealing section 6, the cone faces the cone sealing section 9 and the negative angle torque shoulder 10 Then use the fine turning blade to process the sealing section 6 of the cylinder facing the cylinder, the sealing section 9 of the cone facing the cone and the negative angle torqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com