Mechanical base with functions of buffering and damping

A mechanical and functional technology, which is applied in the field of mechanical bases with buffering and shock absorption functions, can solve the problems of reduced machining dimensional accuracy of processing machinery and equipment, poor buffering and shock resistance of mechanical bases, and affecting product processing quality, so as to reduce the reduction of machining dimensional accuracy , reduce deformation and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

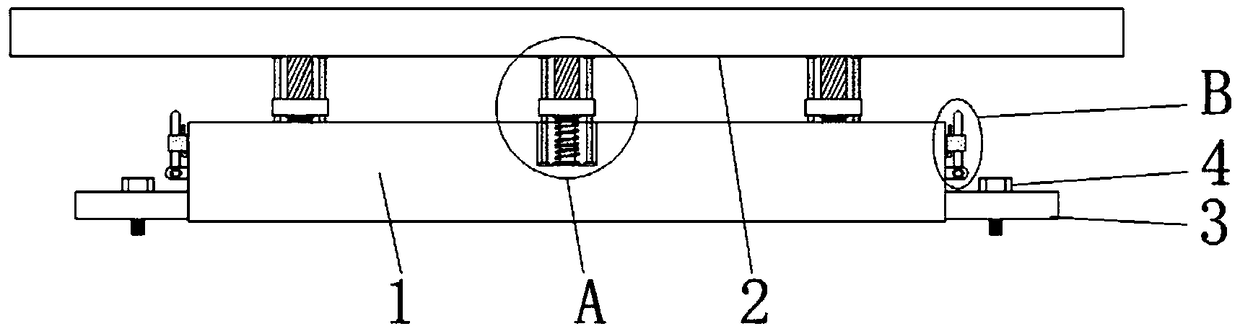

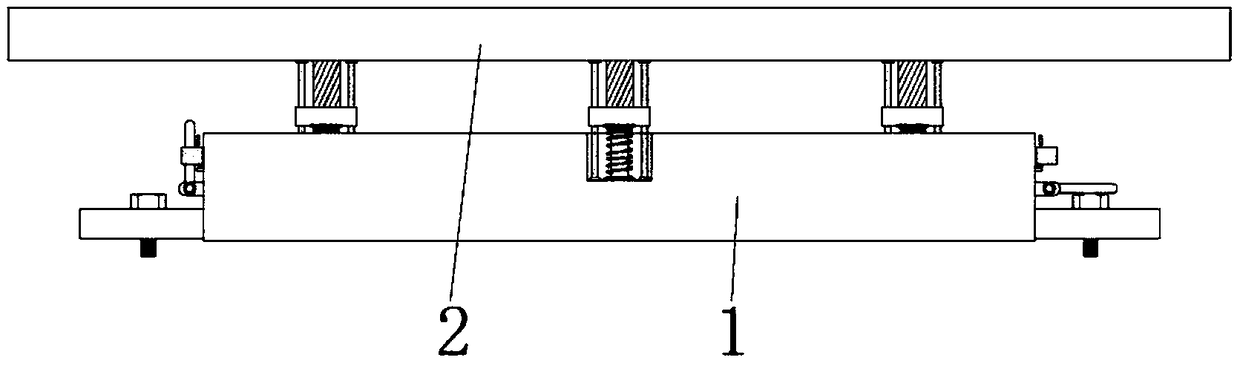

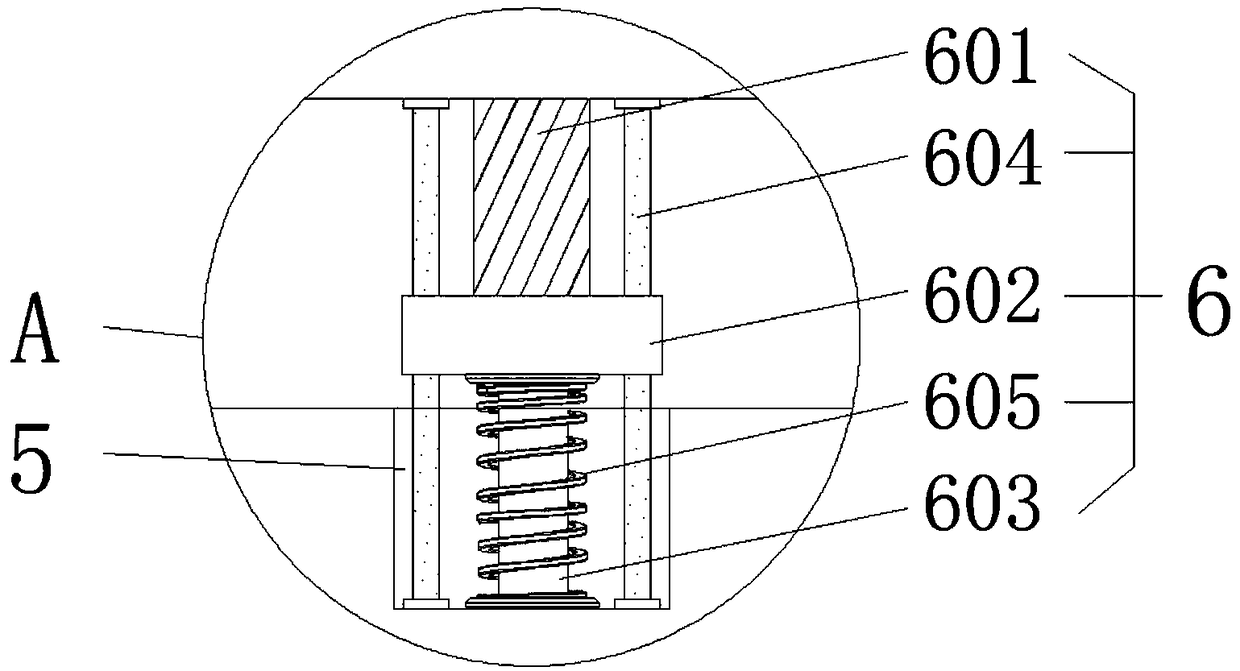

[0023] Such as Figure 1 to 4 As shown, a mechanical base with buffering and shock absorption functions includes a base 2. It is characterized in that it also includes a mounting plate 1 arranged at the lower part of the base 2, evenly and vertically arranged on the base 2 and the mounting plate 1. A number of buffer devices 6 in between, and an anti-loosening device 7 arranged on the mounting plate 1. The buffer device 6 includes a sliding cylinder 601, a sliding rod 603, a limit rod 604 and a spring 605, the sliding cylinder The upper end of the 601 is fixed on the lower end surface of the base 2, the lower part of the sliding cylinder 601 is slidably connected with the upper part of the sliding rod 603, and the lower end of the sliding rod 603 is fixedly installed on the mounting plate 1 and compressed The spring 605 installed at the lower end of the sliding cylinder 601 is sleeved on the sliding rod 603, and the upper and lower ends of the limiting rod 604 are respectively f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com