Method for making composite material club

A technology of composite materials and manufacturing methods, applied to rackets, sports accessories, etc., can solve the problems of reduced striking power, failure to meet requirements, insufficient elasticity, etc., and achieve the effect of reducing processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

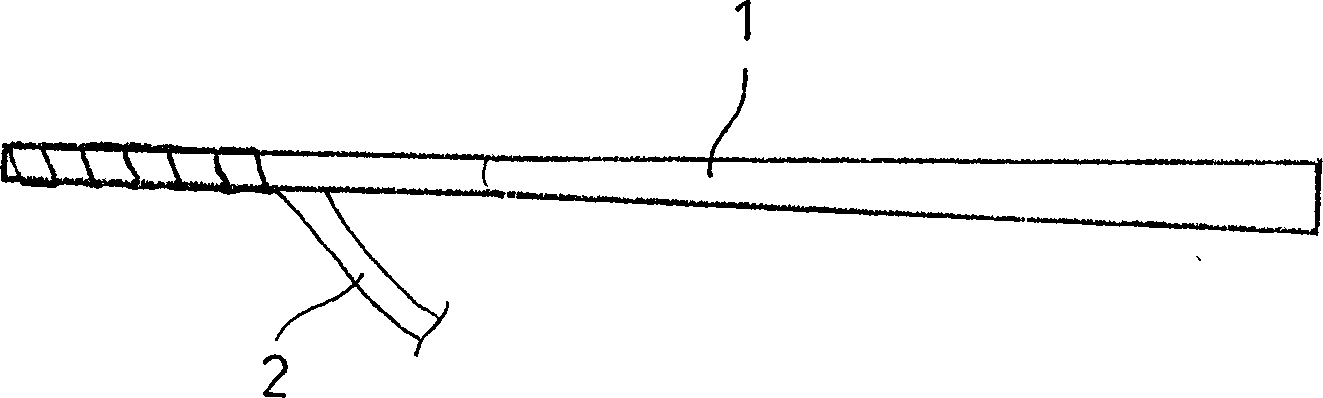

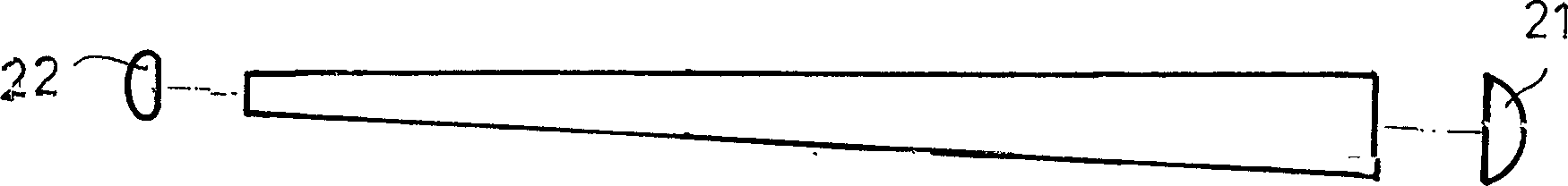

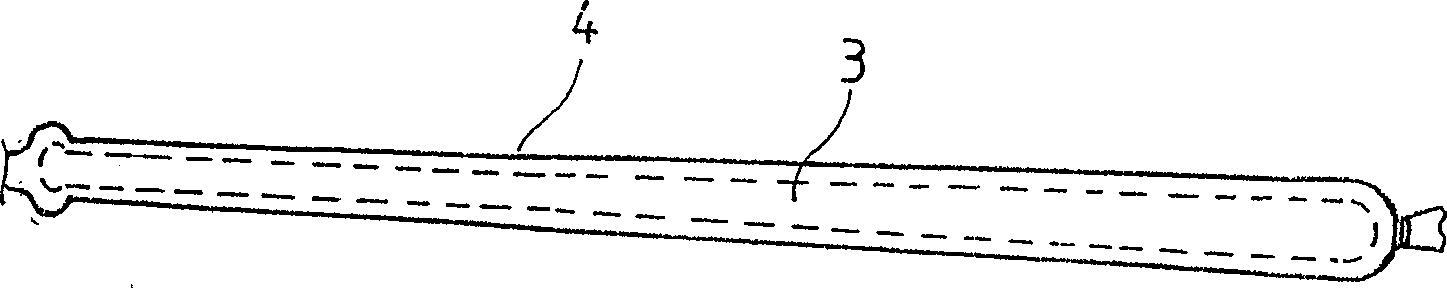

[0017] The present invention is to manufacture bat with composite material, first please refer to image 3 Firstly, a core material 3 with the same shape as the bat but smaller in volume is formed by foaming material, and a sleeve 4 is sheathed on the outer peripheral surface of the core material 3. The sleeve 4 is braided and molded from a composite material, and then as shown in FIG. Figure 4 As shown, it is put into the mold 6, a vacuum pump 61 is connected to one side of the mold 6, and the other side is connected to a resin barrel 62 with a pipeline, and a valve 63 is set in the middle of the pipeline. Firstly, the valve 63 in the pipeline is closed, and the vacuum pump 61 at the other end is started, the inside of the mold 6 is evacuated, so that the sleeve tube 4 is in a state closely attached to the core material 3, then the vacuum pump 61 is closed, and then Heat the mold 6, let the inner core material 3 expand the sleeve tube 4 to an appropriate diameter due to heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com