Patents

Literature

39results about How to "Avoid damage to parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method And Apparatus For Surface Finishing And Support Material Removal (Deci Duo)

ActiveUS20190176403A1Smooth surface finishAvoid damage to partsAdditive manufacturing apparatusIncreasing energy efficiencySpray nozzleSolid particle

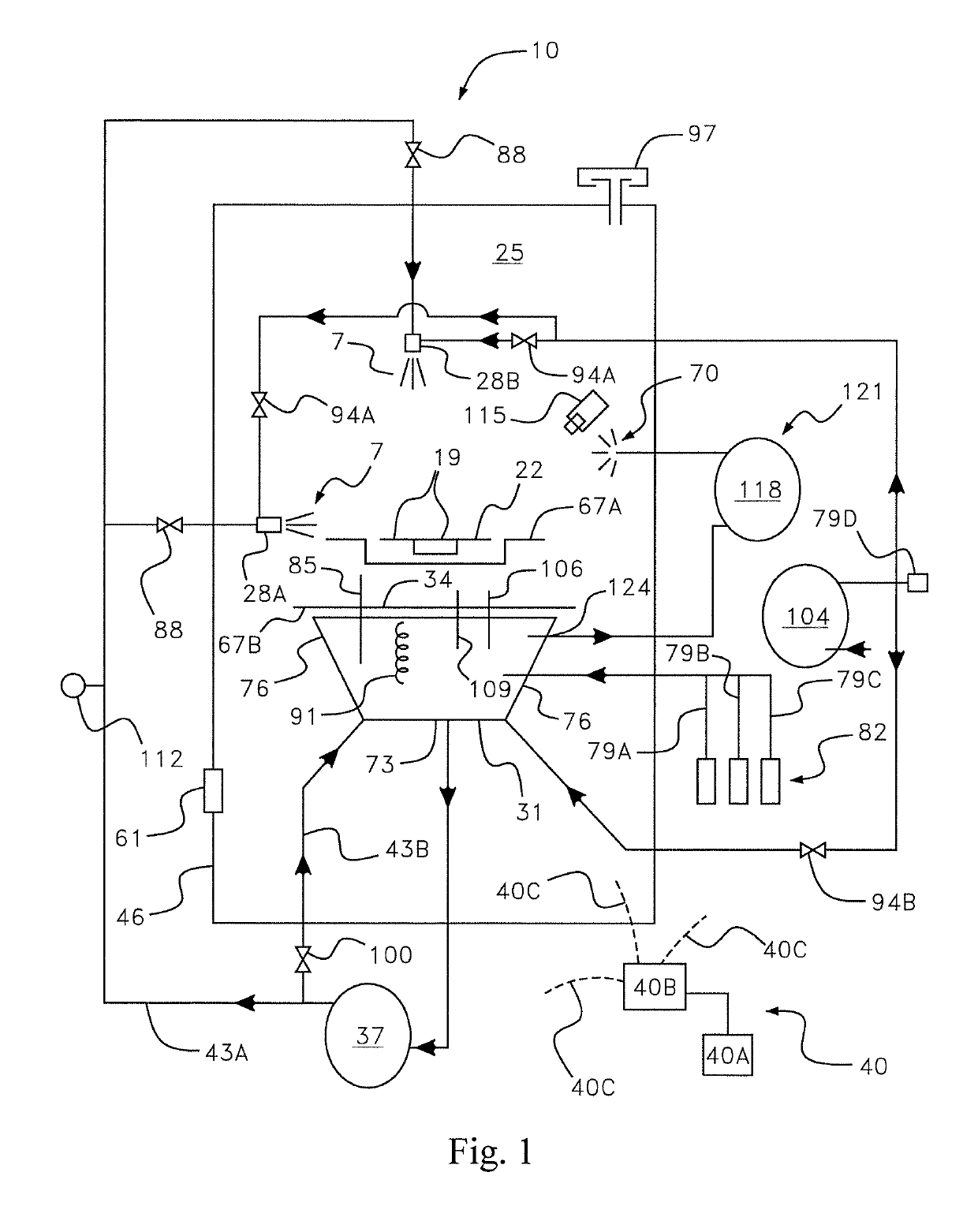

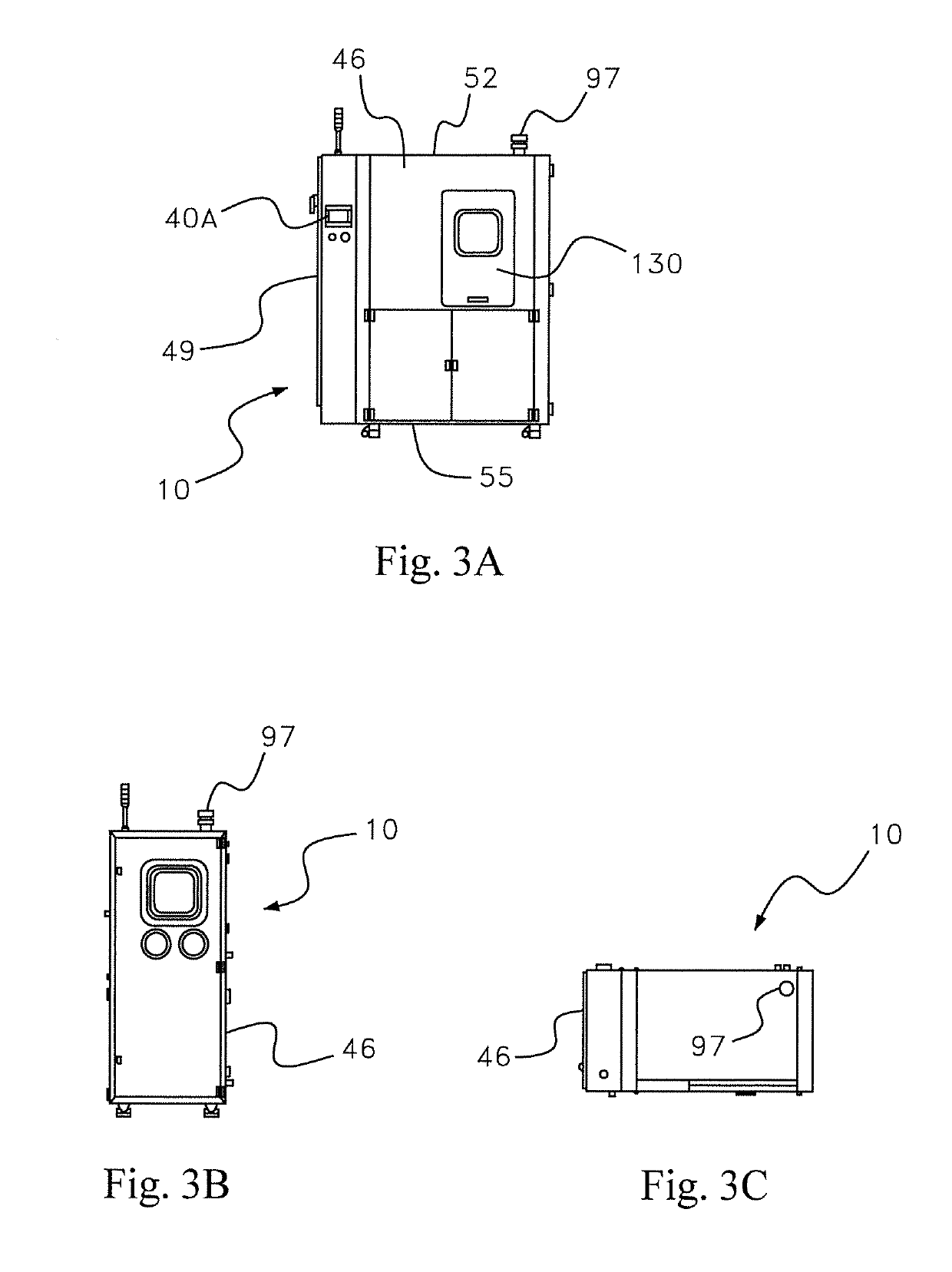

Apparatuses and methods for removing support material from and / or smoothing surfaces of an additive-manufactured part are disclosed. Apparatuses may include a spraying chamber, a support surface within the spraying chamber, and one or more nozzles having the ability to spray a fluid at the additive-manufactured parts. The fluid may include a liquid and solid particles carried by the liquid. The support surface may have the ability to support the additive manufactured part. The apparatus may include a tank having the ability to hold at least some of the fluid. A heater may be included for heating the fluid to a desired temperature.

Owner:POSTPROCESS TECH INC

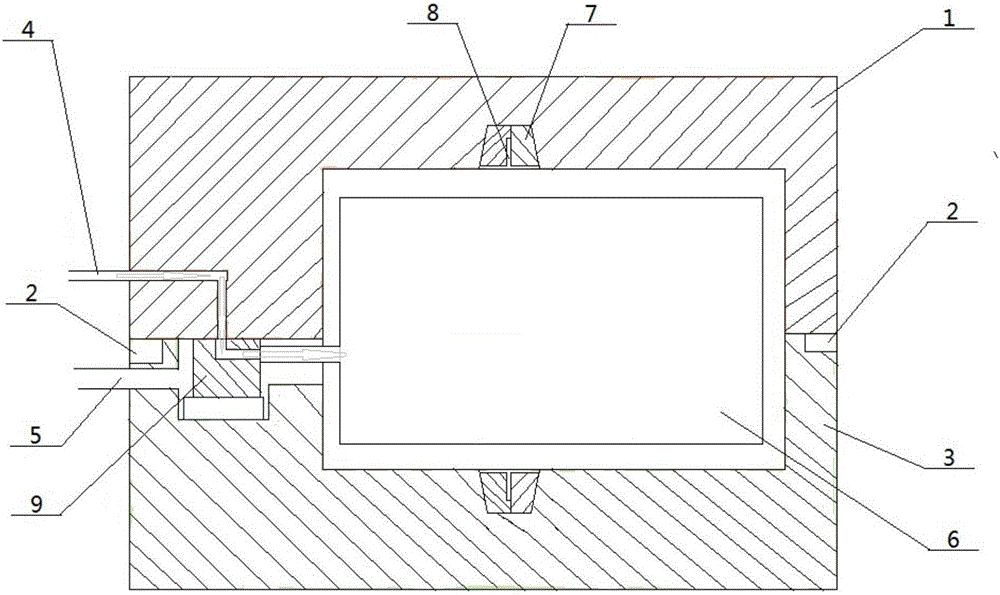

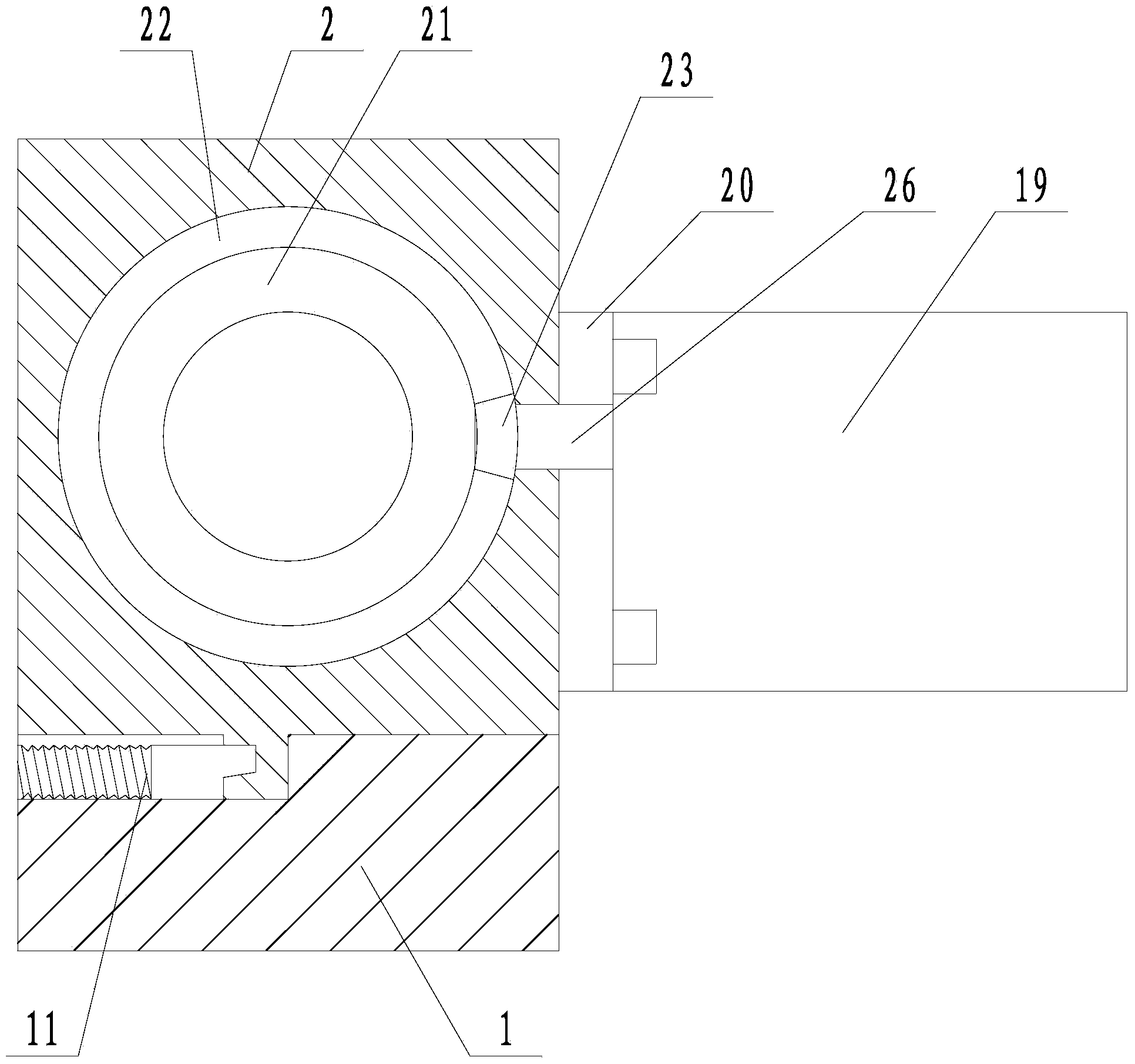

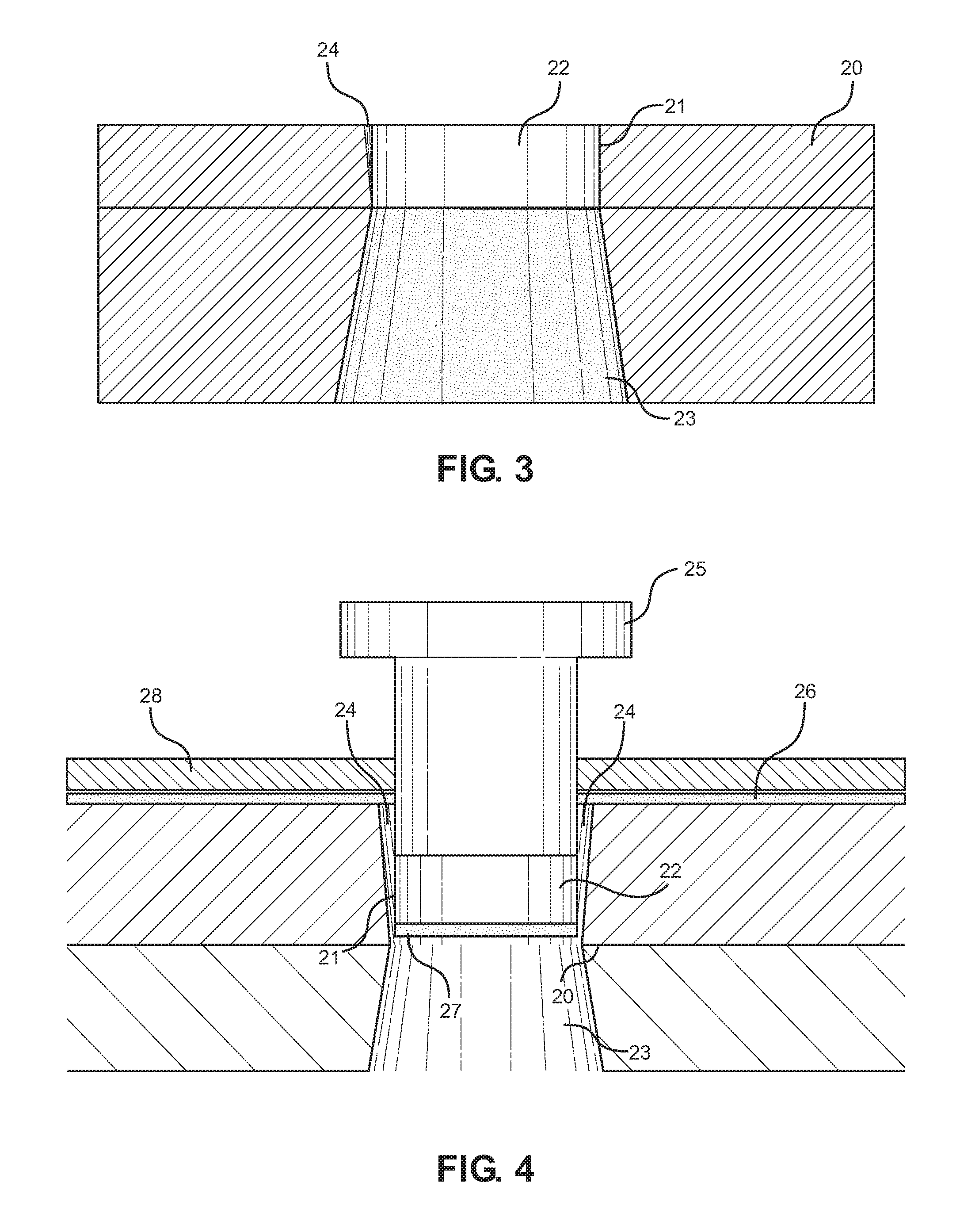

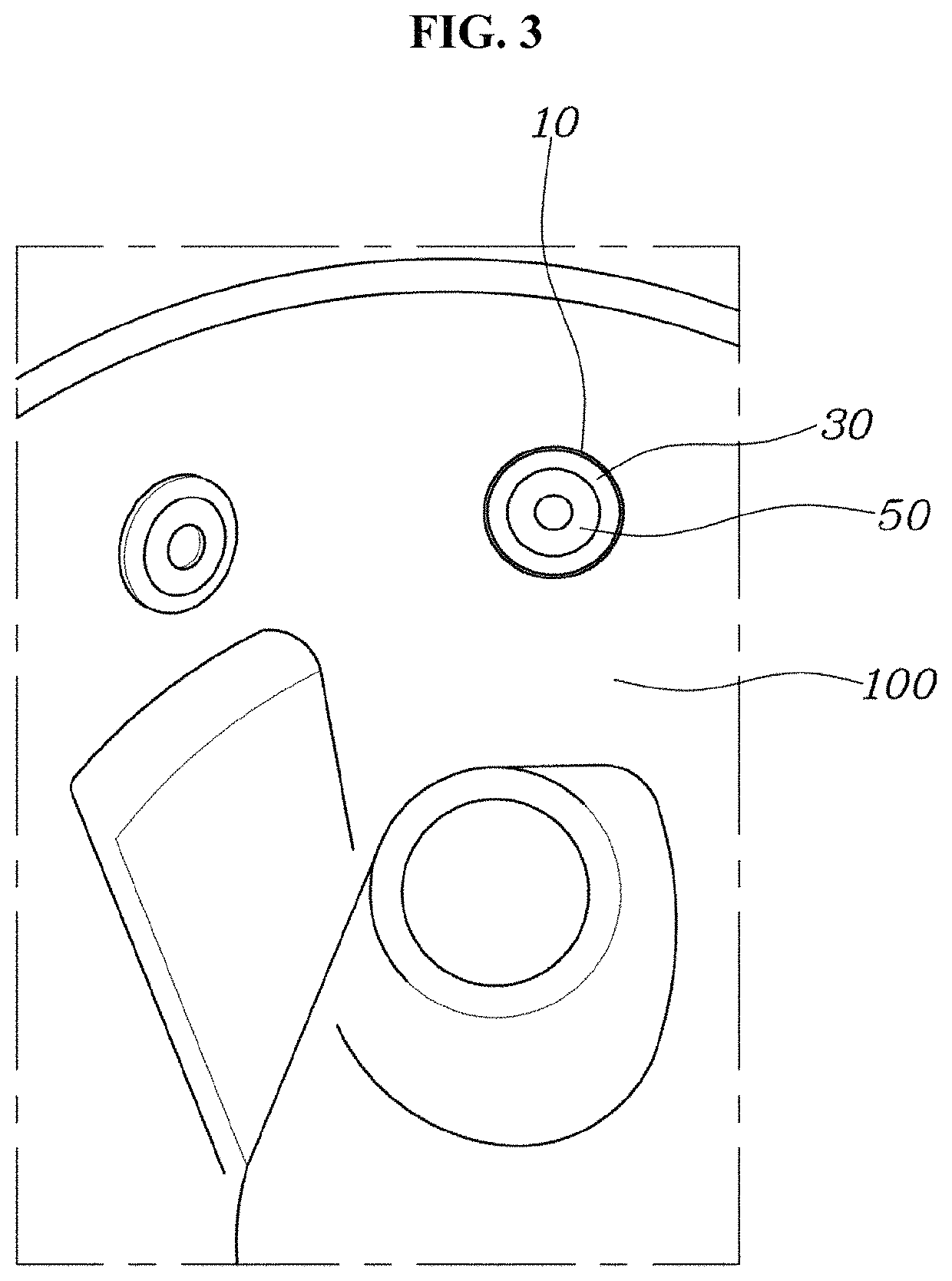

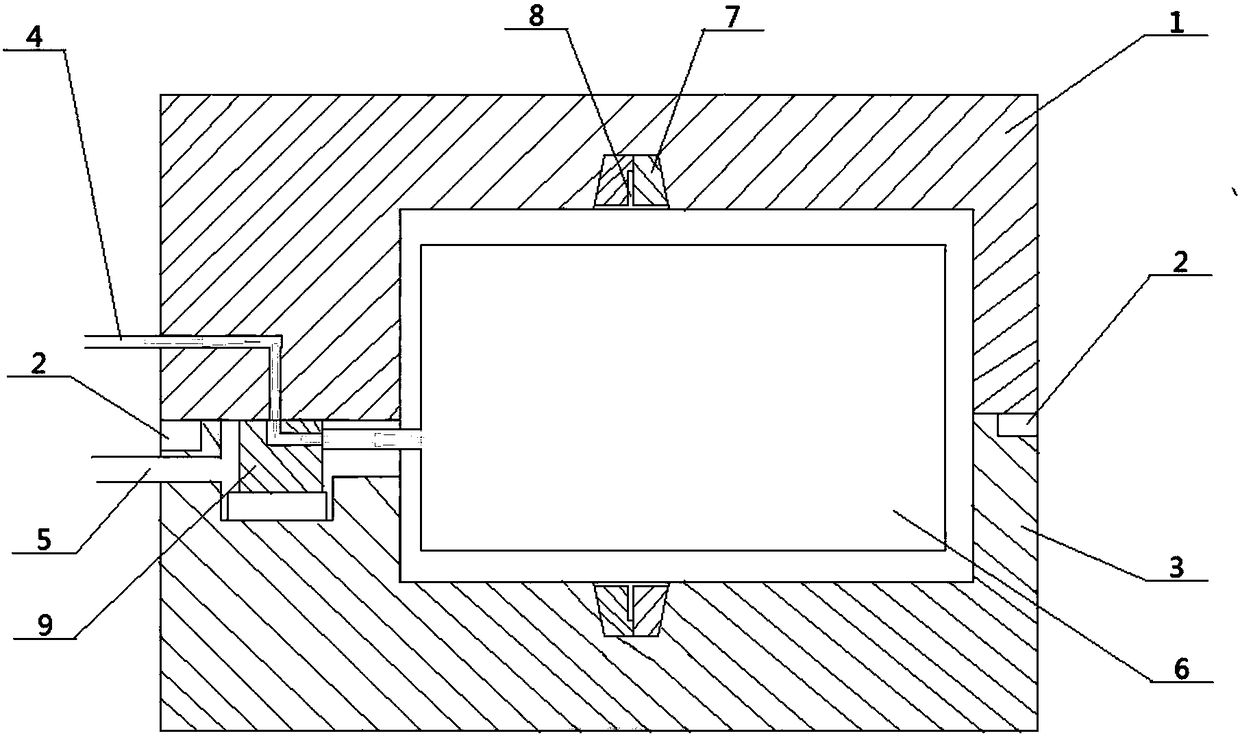

Superplastic forming diffusion connection integral forming mold and method for parts with reinforcing ribs

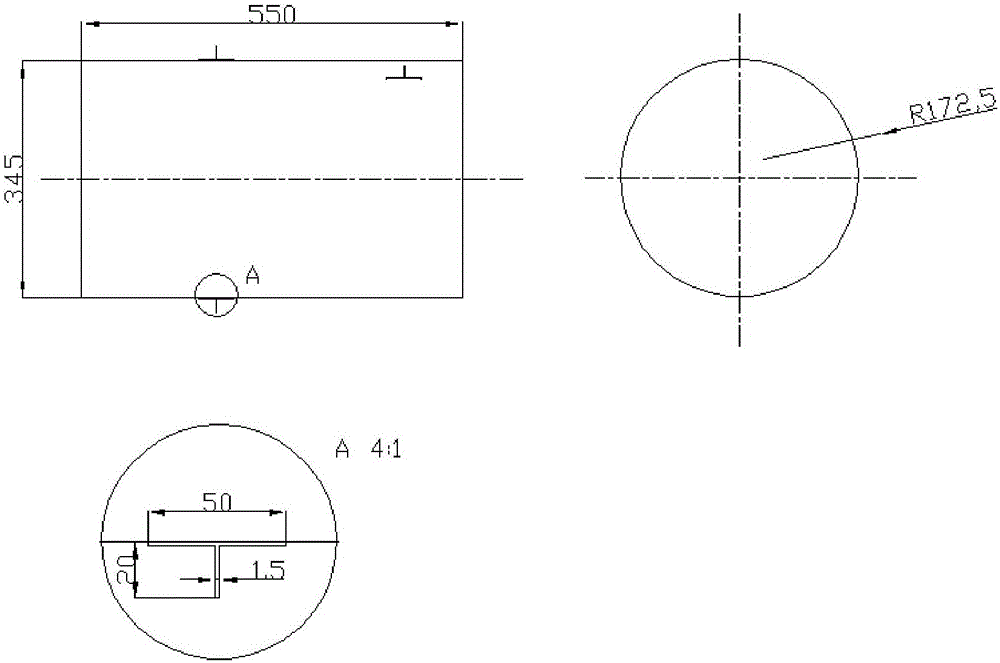

The invention discloses a superplastic forming diffusion connection integral forming mold and method for parts with reinforcing ribs. According to the part size, the size of a part blank is calculated, the blank is circled to be welded to form a cylindrical blank, a cylinder obtained after mold insert, reinforcing and seal operation finishing is put into a mold cavity, a seal ring is arranged on the mold, after mold assembly, heating is carried out, after the superplastic process is finished, the reinforcing ribs and the cylinder are completely attached to be subject to the diffusion connection process, cooling and mold stripping are carried out, and the cylindrical part with the reinforcing ribs is obtained. By means of the superplastic forming / diffusion connection integral forming technology, the titanium alloy cylindrical part with the reinforcing ribs is formed, the problem that cooling forming of titanium and a titanium alloy is difficult is solved, and it is ensured that the formed part is free of springback, the appearance is accurate and the machining allowance is small; the material utilization rate is improved, the weight of part components is effectively reduced, the working procedure and the cost of assembling connection are reduced, the mold cavity and a part inner cavity are independently sealed, the working procedure needed by the part is further reduced, the cost is reduced, and the time benefits of part machining are improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

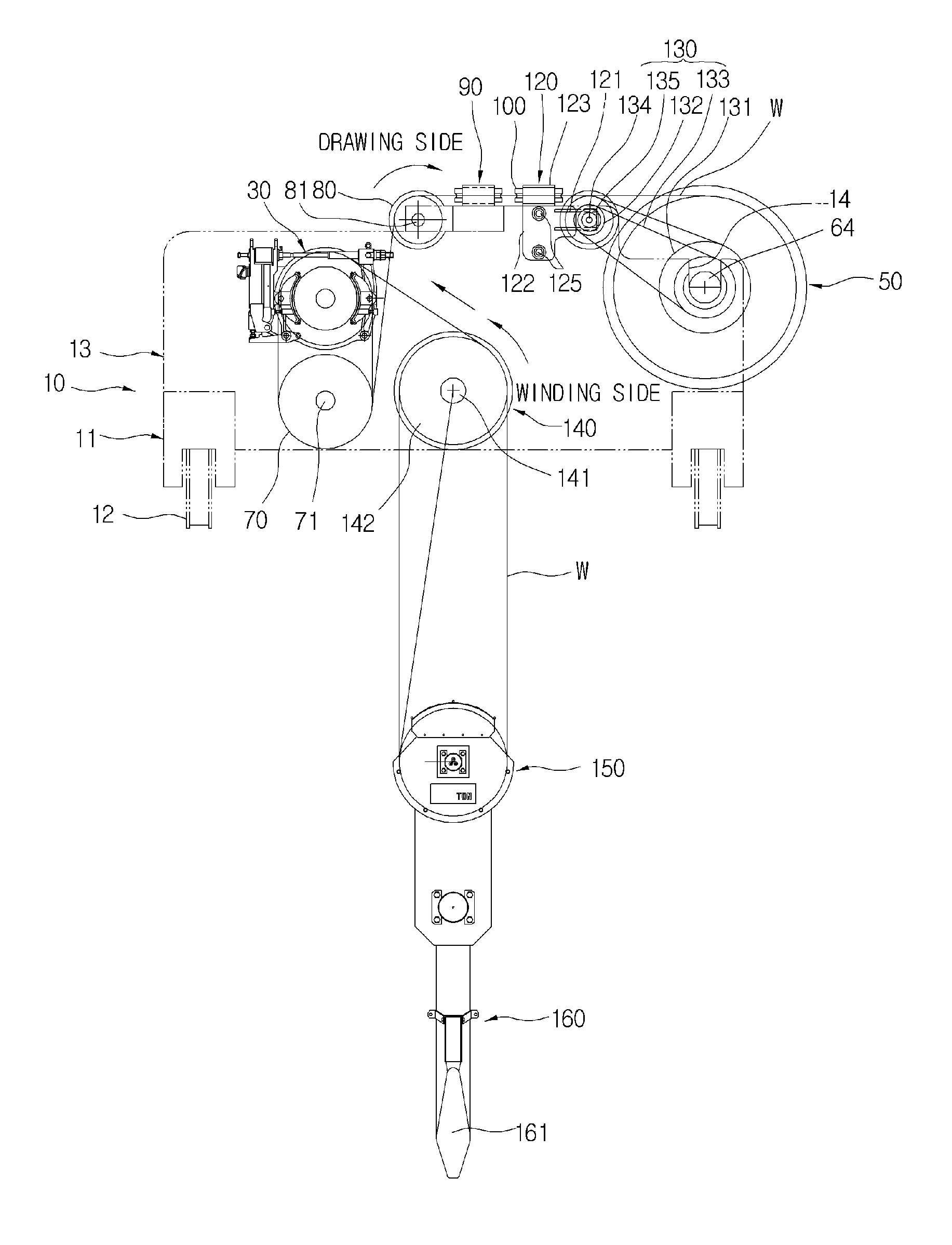

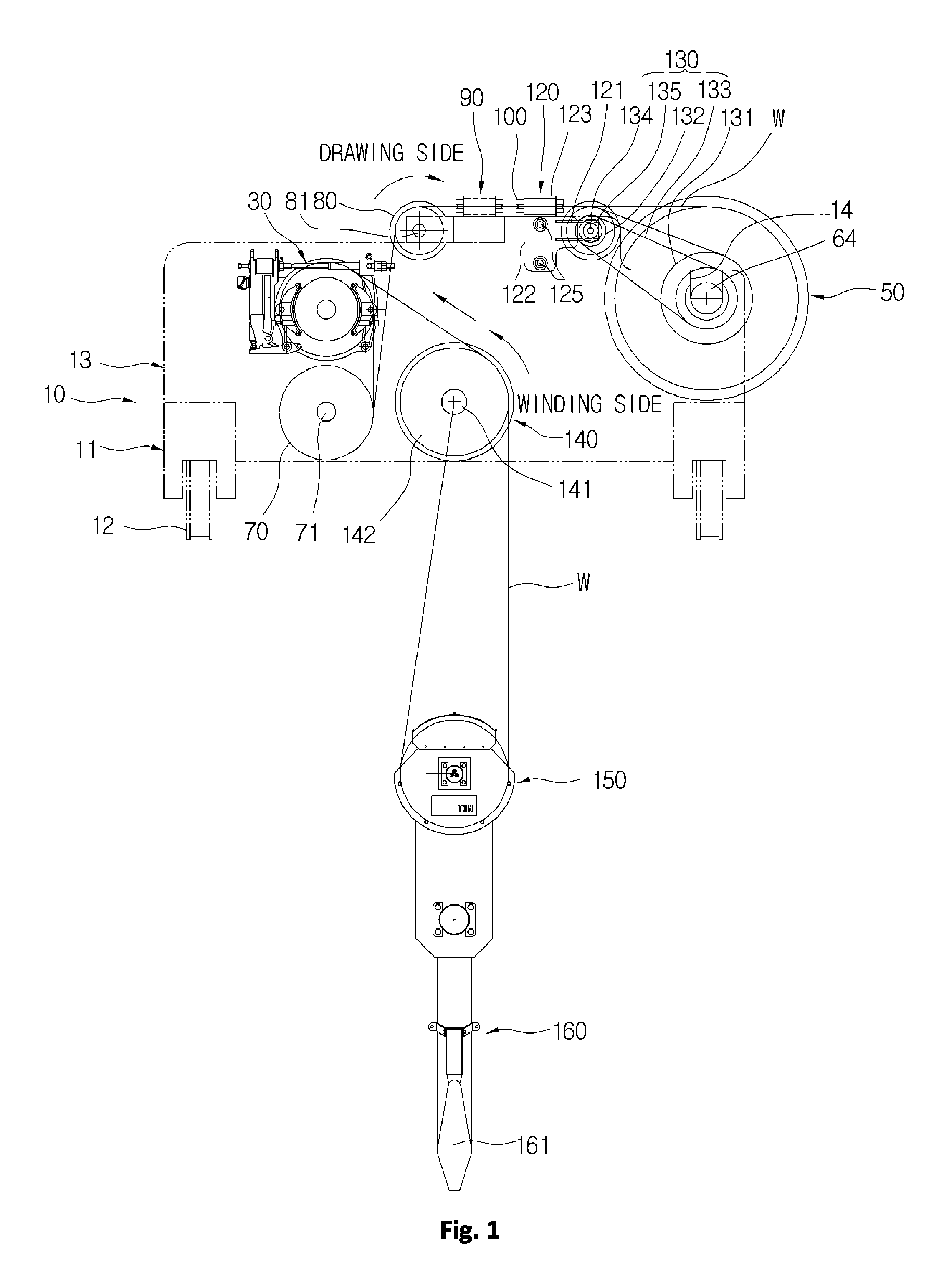

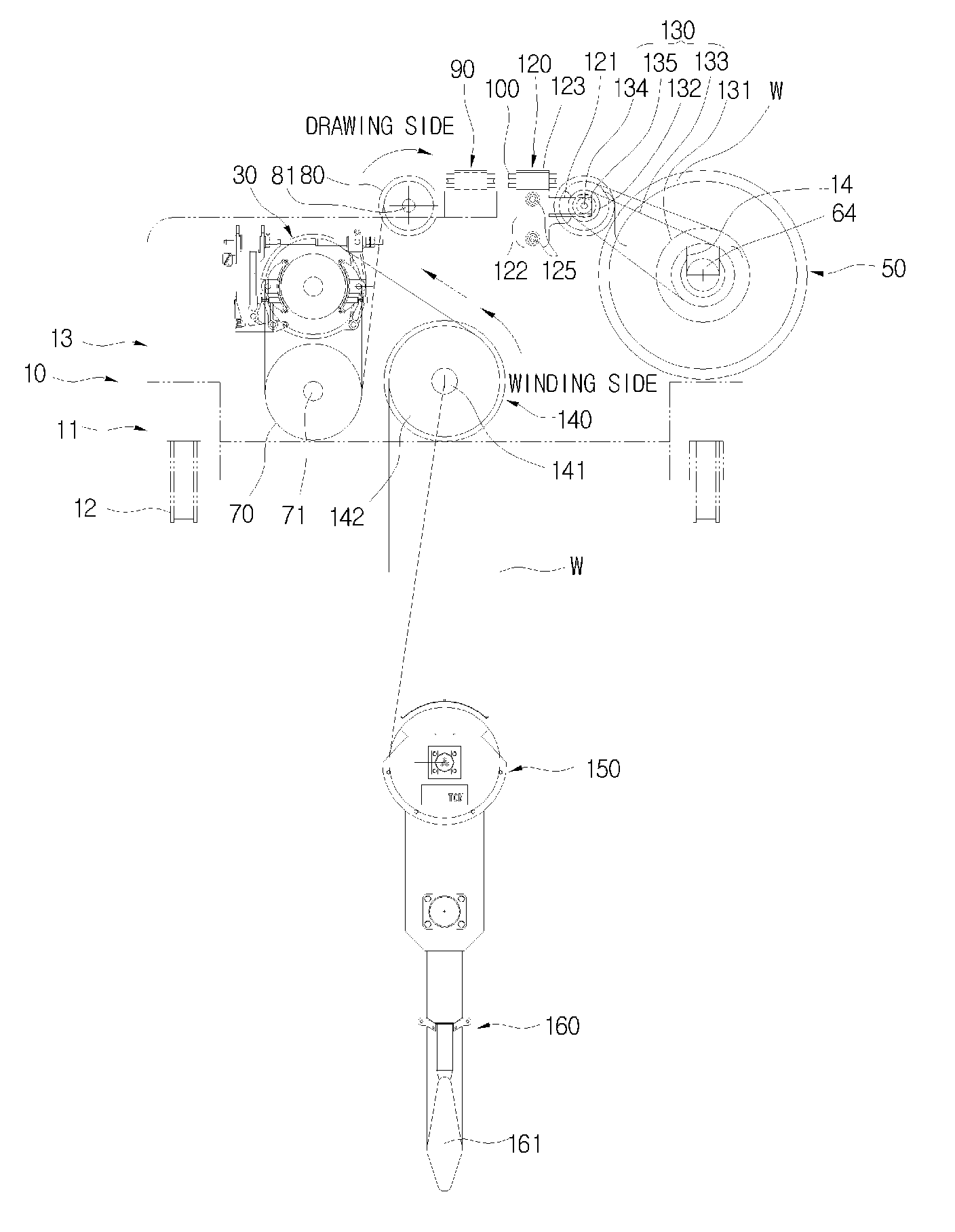

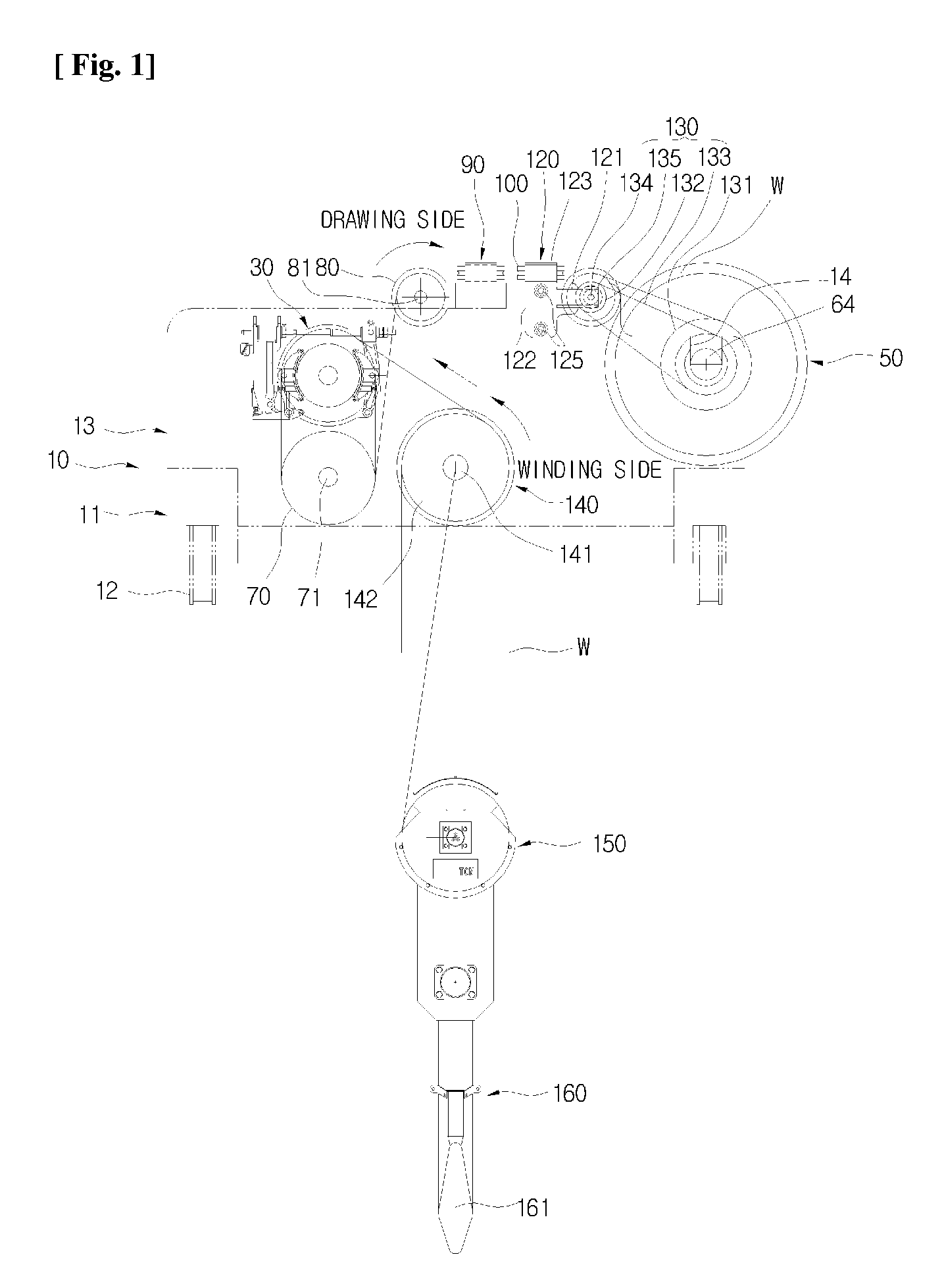

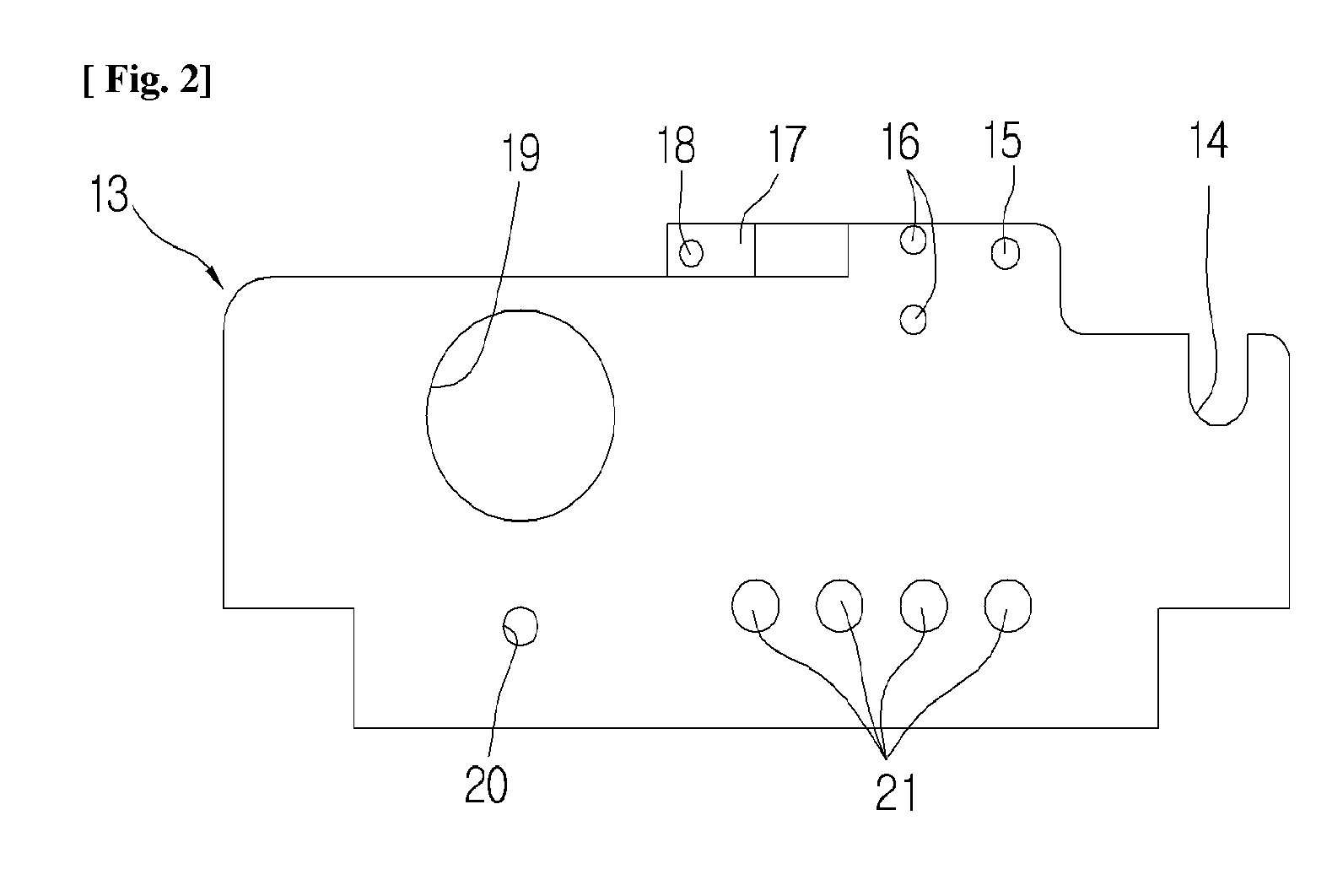

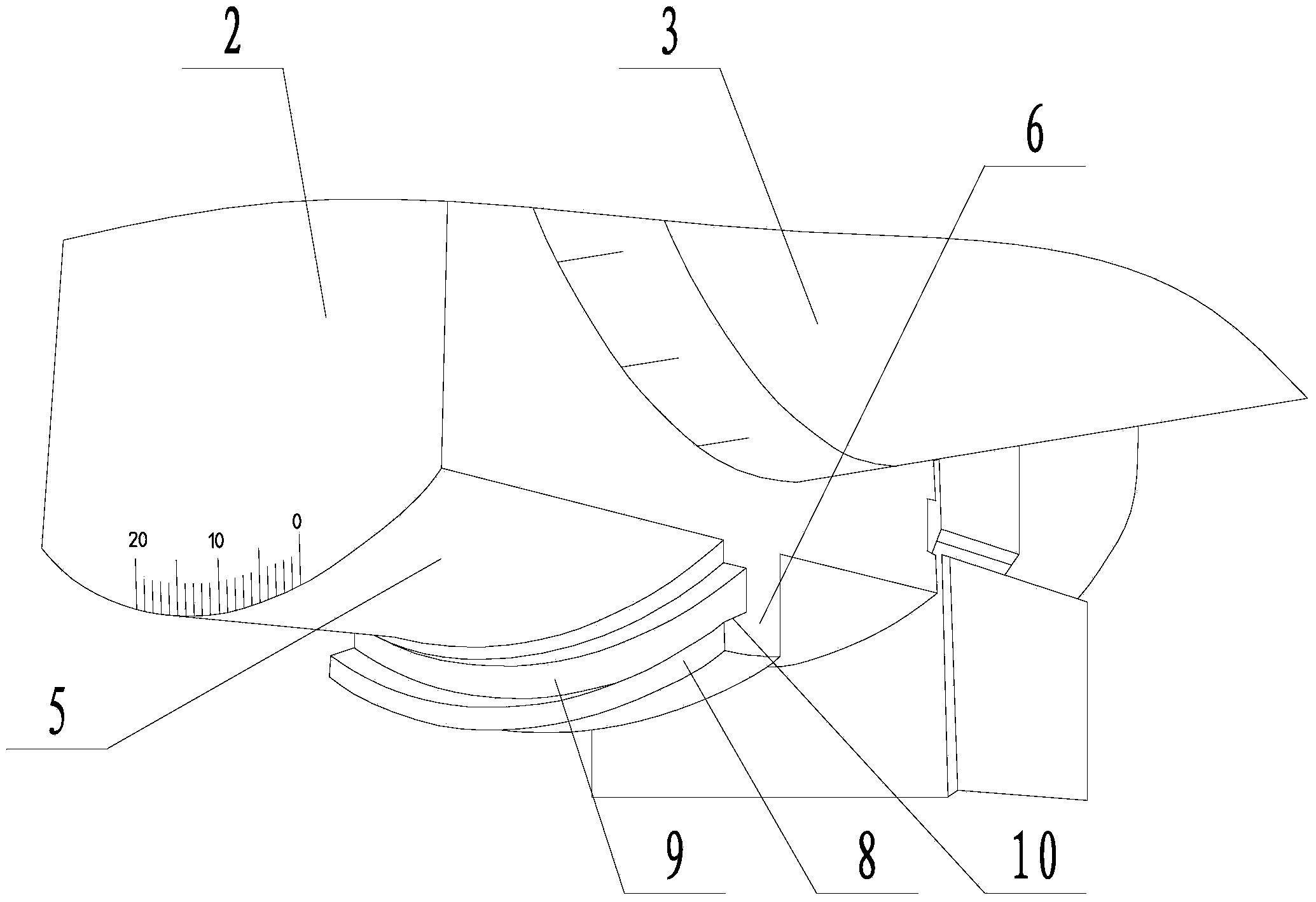

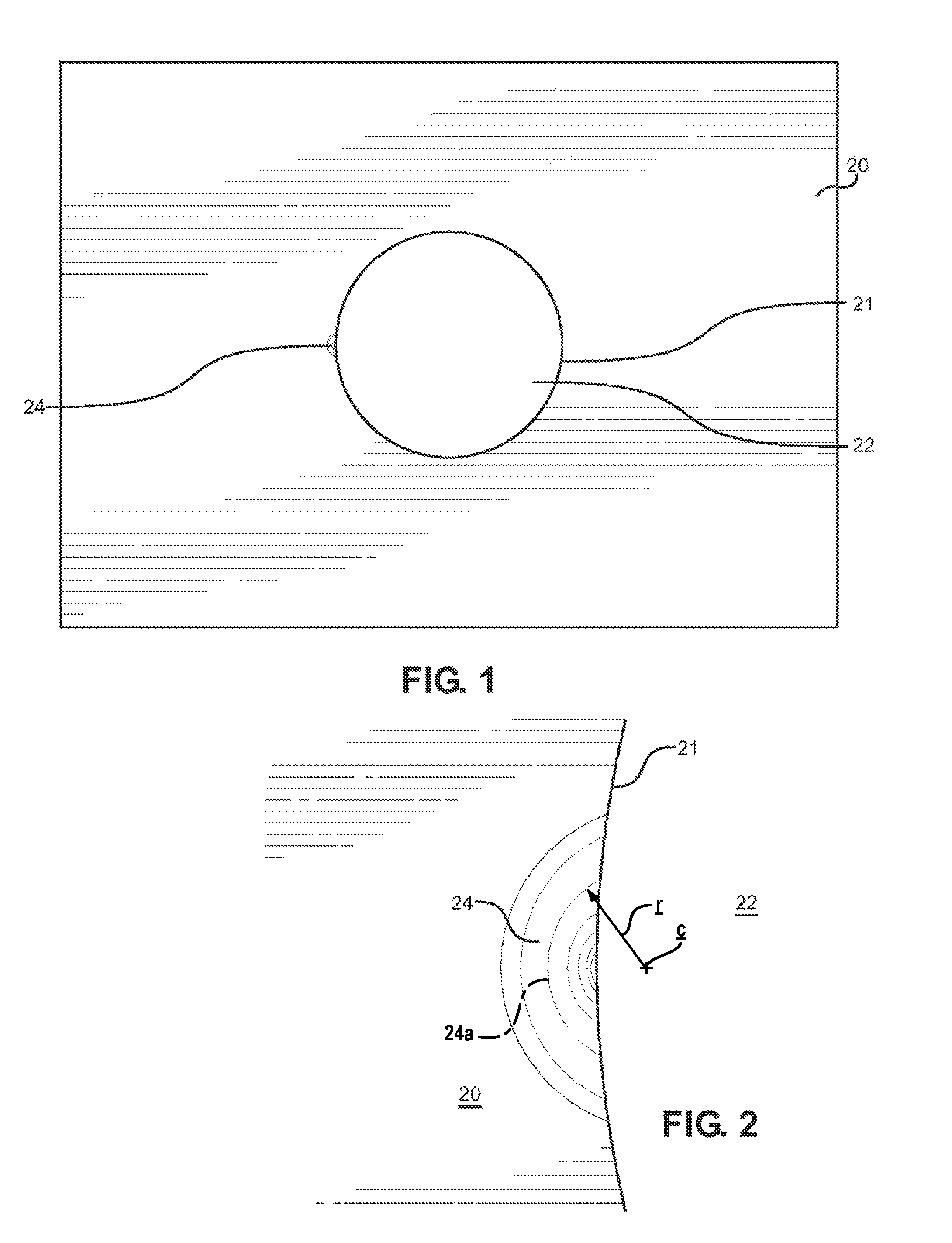

Hoist using friction wheel

InactiveUS8616527B2Extended range of motionAvoid damage to partsWinding mechanismsLoad-engaging elementsReciprocating motionEngineering

Disclosed is a hoist using a friction wheel to maximize horizontal movement of a load to be lifted while preventing a wire from deviating from a winding orbit while being wound on a wire drum, the friction wheel having a simplified configuration and being designed to stably support horizontal and vertical movable guide rollers. The hoist includes a single friction wheel on which a wire at a winding side is wound, a wire drum on which the wire at a drawing side is wound, a driven friction wheel through which the wire is guided from the friction wheel to the wire drum, vertical and horizontal stationary guide rollers and vertical and horizontal movable rollers for guidance of the wire, a movable roller mount to horizontally reciprocate the horizontal and vertical movable guide rollers, and upper and lower sheaves to guide the wire to the friction wheel.

Owner:KG INC

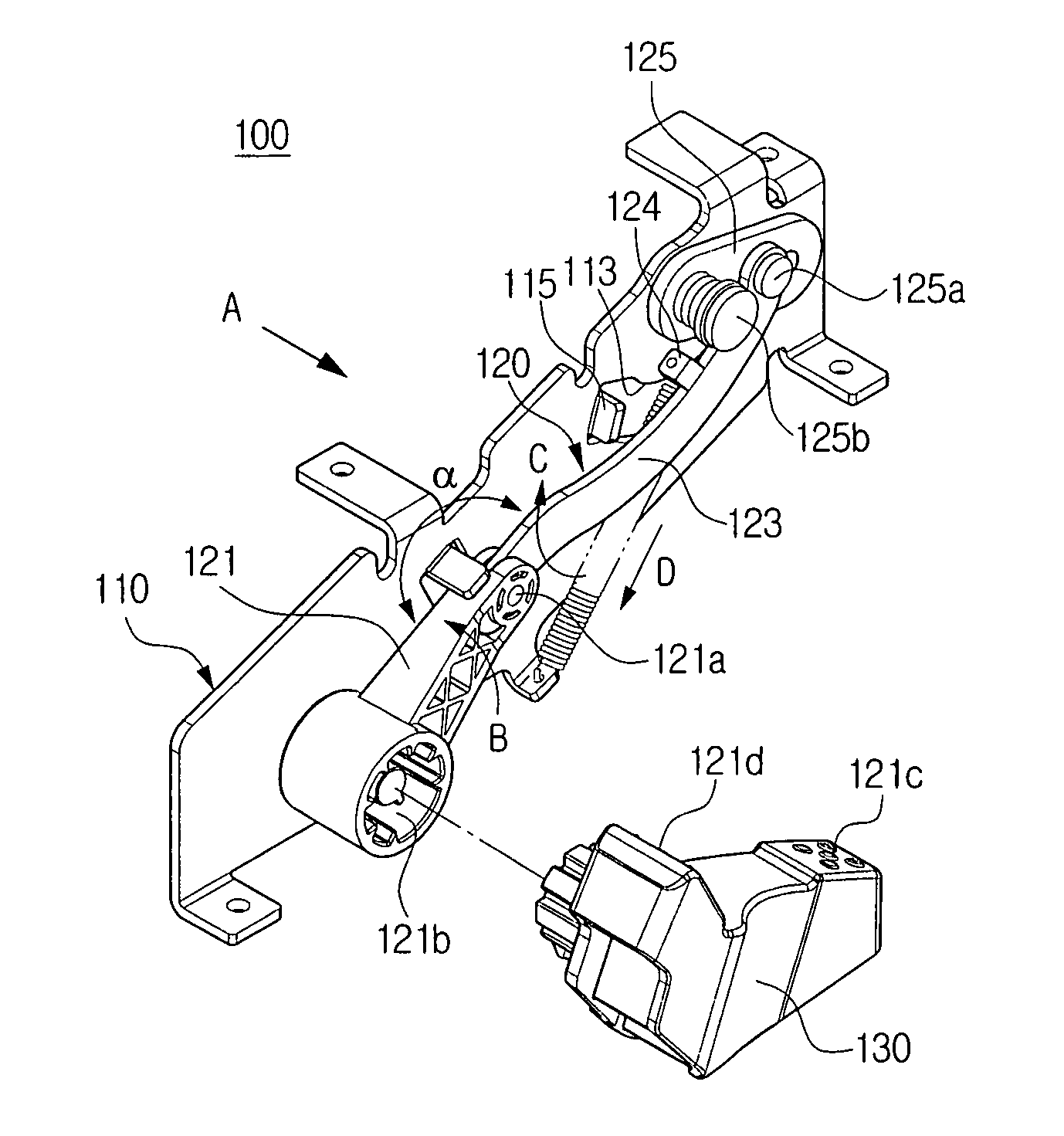

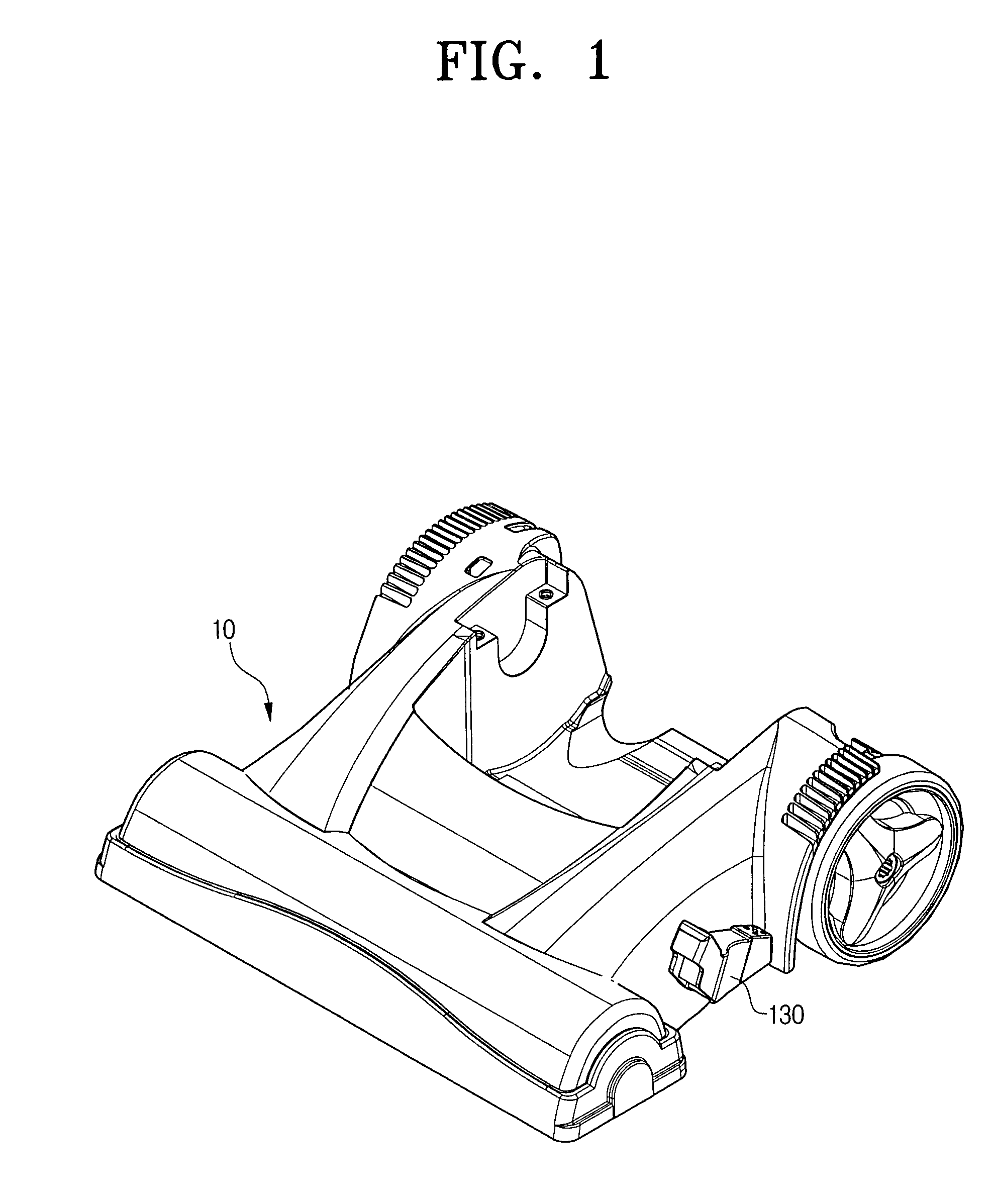

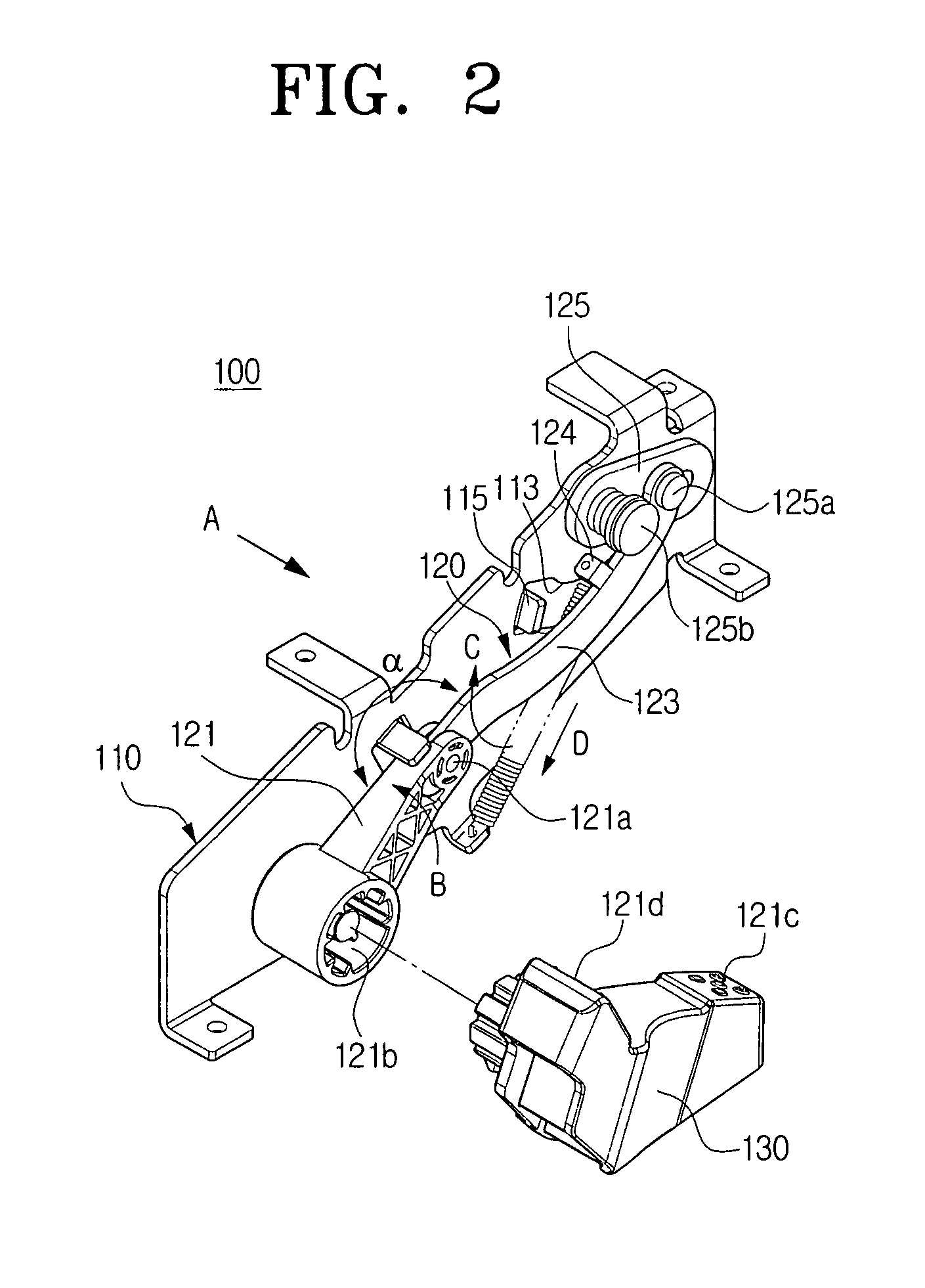

Driving control apparatus of rotary brush for use in vacuum cleaner

InactiveUS7562415B2Avoid damage to partsAccurate and stableCarpet cleanersFloor cleanersDrive shaftVacuum cleaner

A driving control apparatus of a rotary brush, which controls a drive of the rotary brush disposed in a suction body of a vacuum cleaner, is disclosed. The driving control apparatus includes a fixing bracket disposed in a suction body of a vacuum cleaner, a link unit pivotably connected to the fixing bracket, a pedal unit connected to one side of the link unit, and a pulley unit to move in combination with the link unit and to connect or separate a driving belt to or from a driving shaft, and the pulley unit is rotated in the same direction as a rotating direction of the driving belt when coming in contact with the driving belt.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Hoist using friction wheel

InactiveUS20120305869A1Extended range of motionAvoid damage to partsWinding mechanismsLoad-engaging elementsReciprocating motionEngineering

Disclosed is a hoist using a friction wheel to maximize horizontal movement of a load to be lifted while preventing a wire from deviating from a winding orbit while being wound on a wire drum, the friction wheel having a simplified configuration and being designed to stably support horizontal and vertical movable guide rollers. The hoist includes a single friction wheel on which a wire at a winding side is wound, a wire drum on which the wire at a drawing side is wound, a driven friction wheel through which the wire is guided from the friction wheel to the wire drum, vertical and horizontal stationary guide rollers and vertical and horizontal movable rollers for guidance of the wire, a movable roller mount to horizontally reciprocate the horizontal and vertical movable guide rollers, and upper and lower sheaves to guide the wire to the friction wheel.

Owner:KG INC

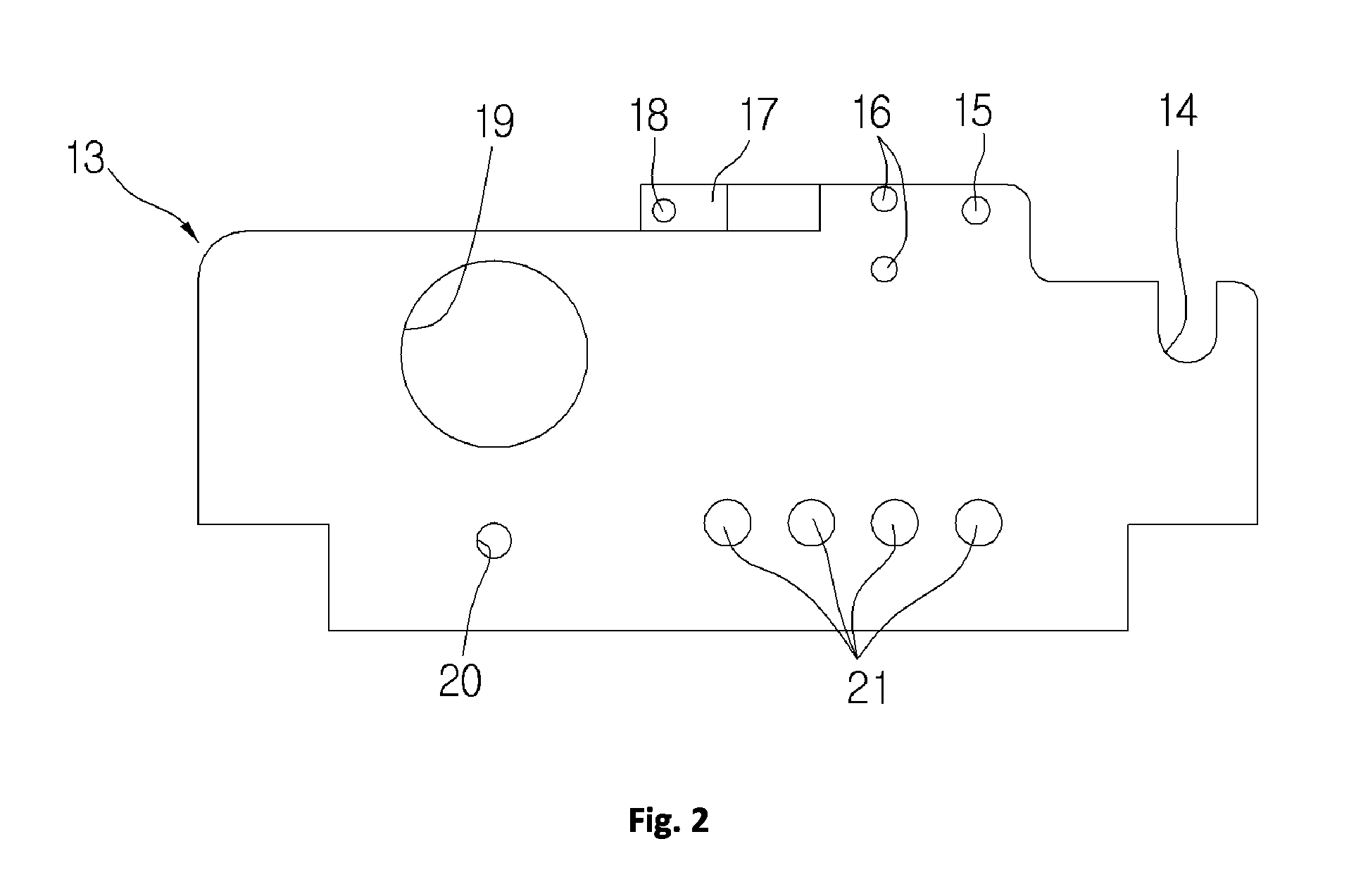

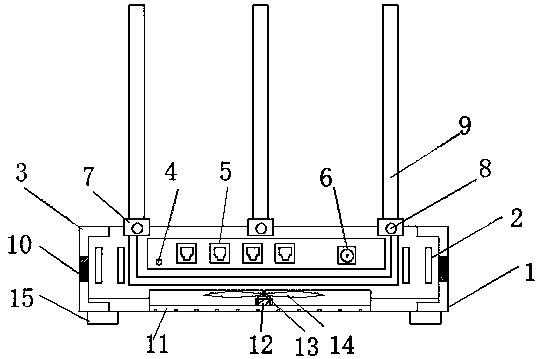

Heat-radiating and anti-falling router

InactiveCN107911310AAvoid damage to partsSimple structureModifications by conduction heat transferData switching networksSmart applianceComputer fan

The present invention relates to the field of smart home technology, and discloses a heat-radiating and anti-falling router. The heat-radiating and anti-falling router comprises a router body, a heat-radiating port is arranged at the surface of the router body, anti-falling sleeves are respectively fixedly installed at four corners of the router body, the router body is provided with a reset key,and one side of the reset key is provided with network cable holes. The anti-falling router drives the rotation of a rotating shaft through a motor installed at the bottom portion, drives the rotationof a fan blade through the rotating shaft, employs the fan blade to perform heat radiation of the internal portion of the router, employs a filter screen and a dust screen to exhaust hot air, employsthe heat-radiating port to perform secondary heat radiation of the router, employs a cooling fan and the filter screen to achieve dust prevention and heat radiation of the router and employs anti-falling sleeves installed at four corners of the router to avoid part damaging after the router is fell off, and therefore, the anti-falling router is simple in structure composition, convenient to use and very wide in application prospect.

Owner:ZHENGZHOU WEIYIJIA ELECTRONICS TECH CO LTD

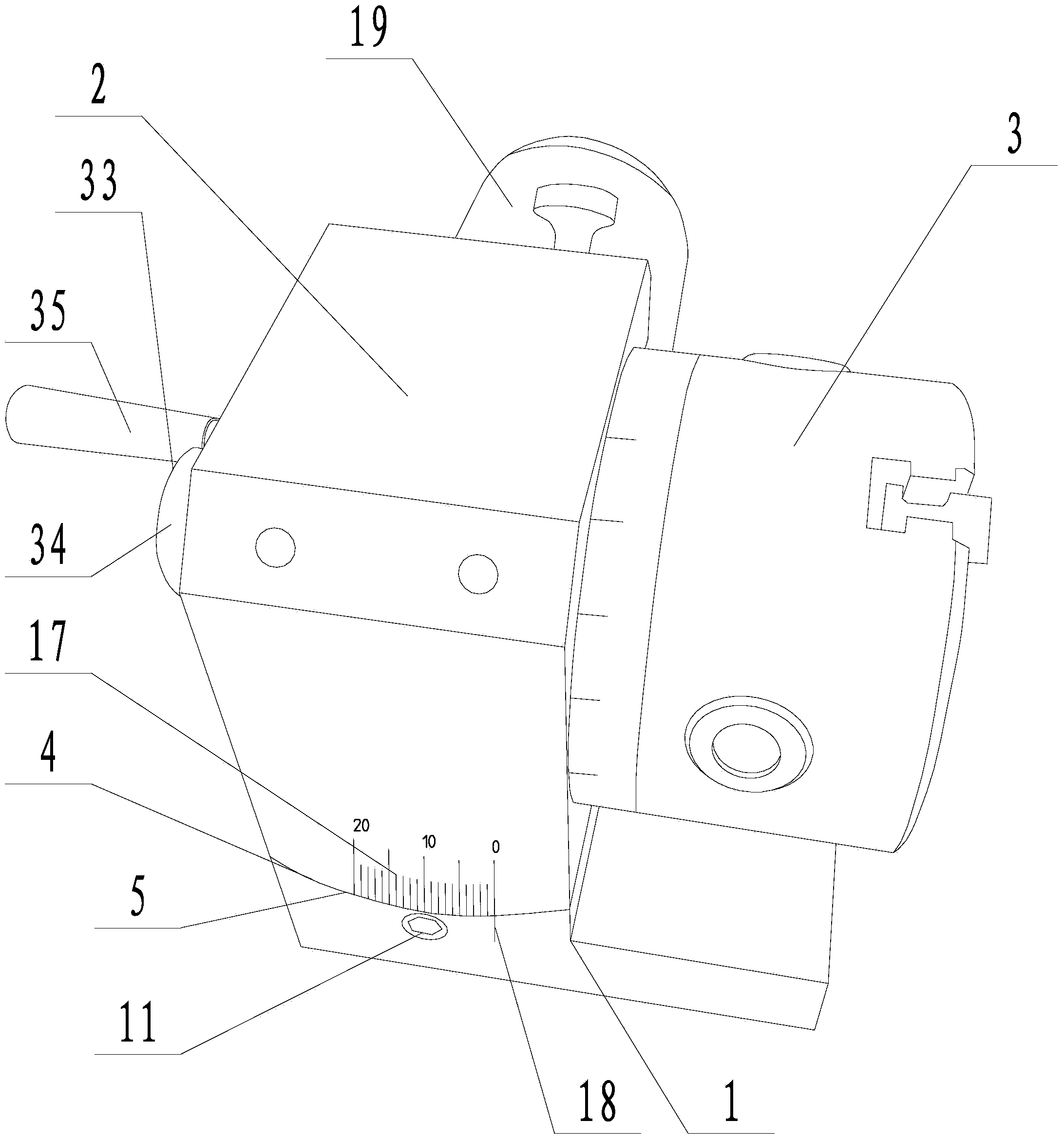

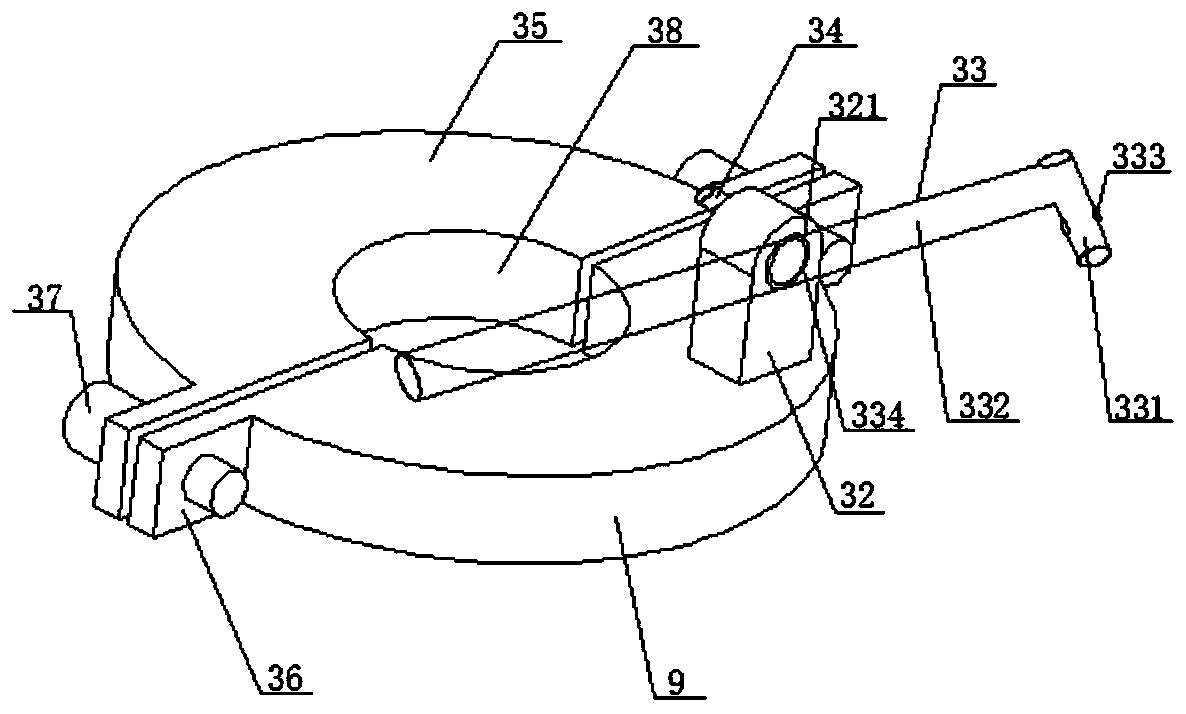

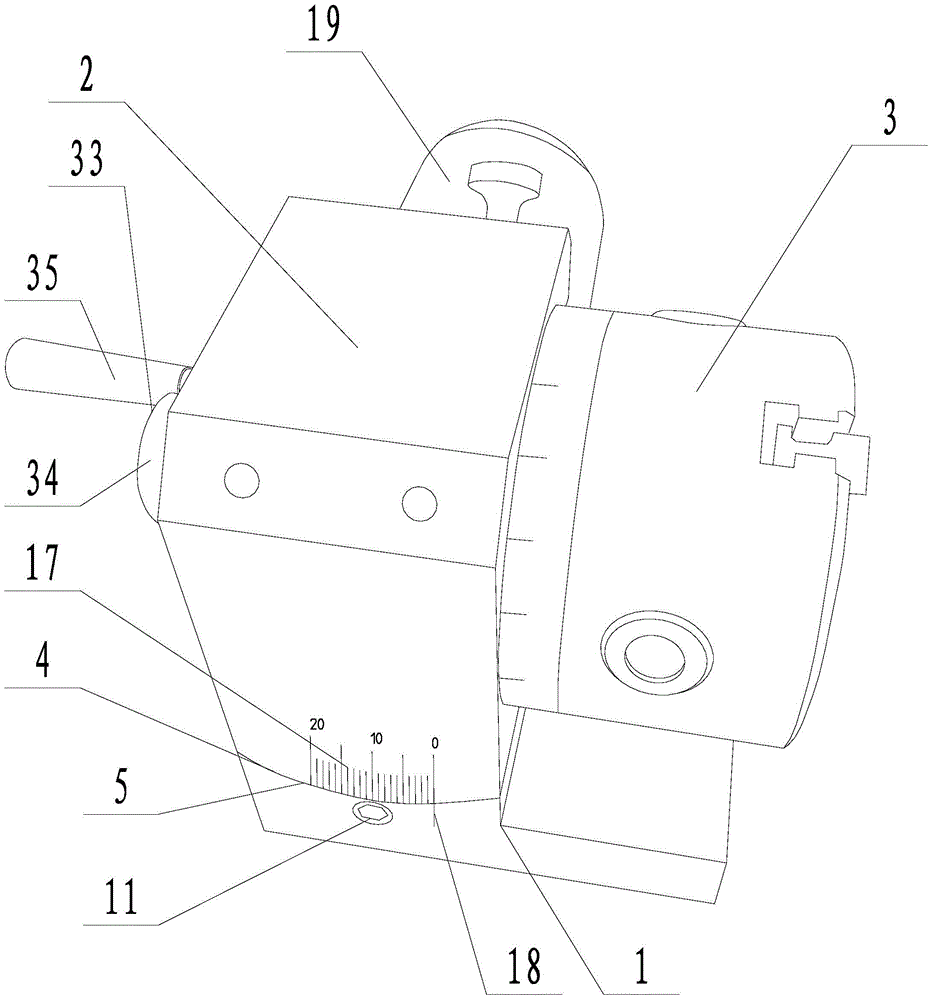

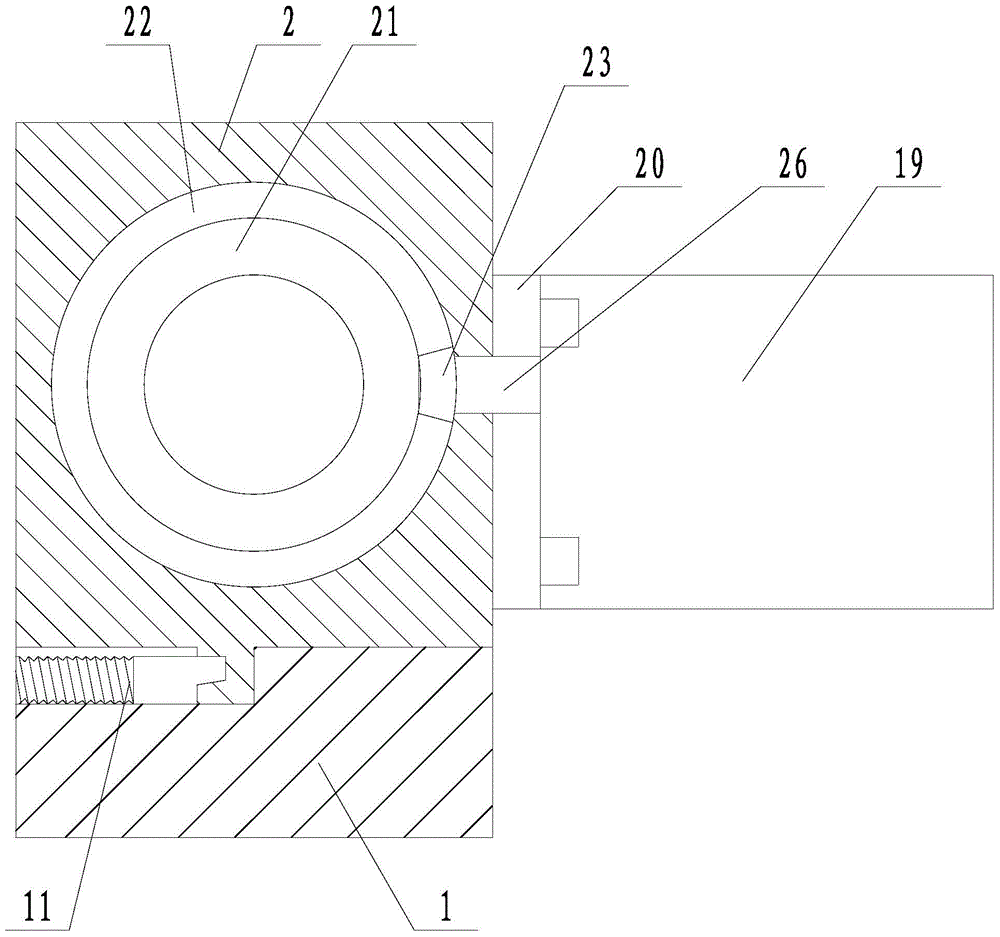

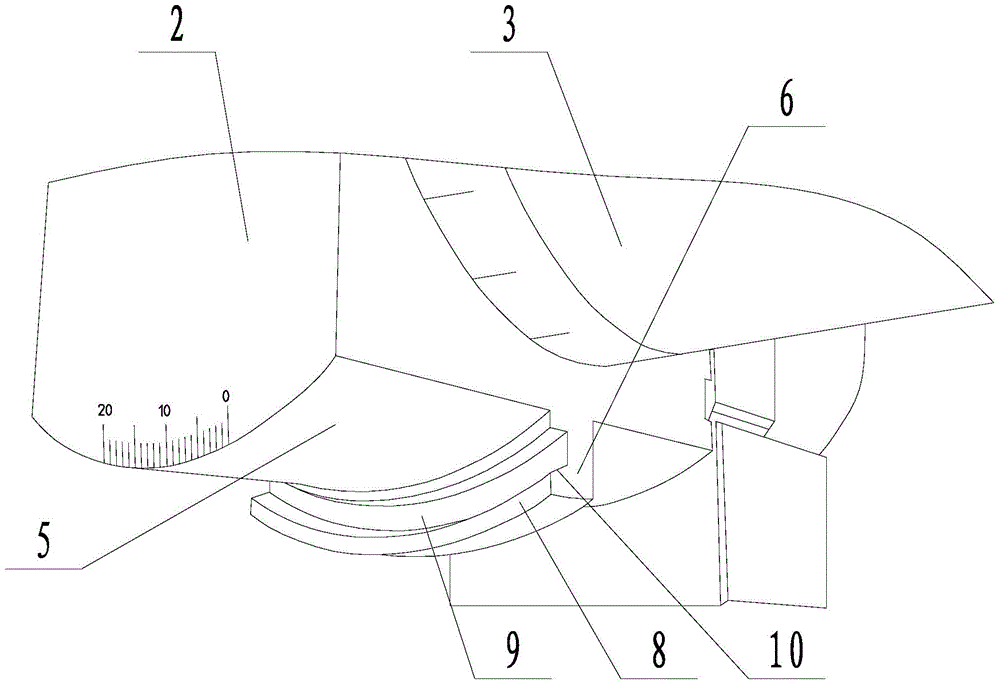

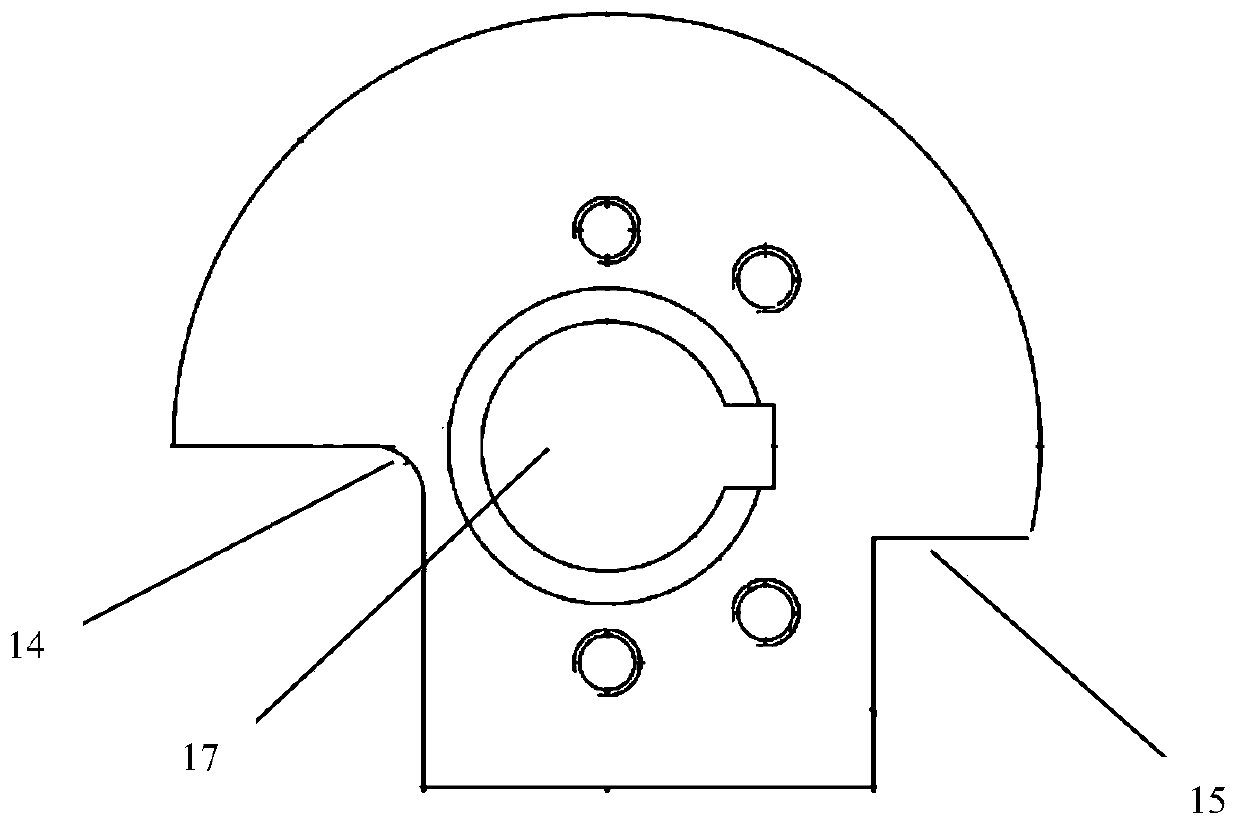

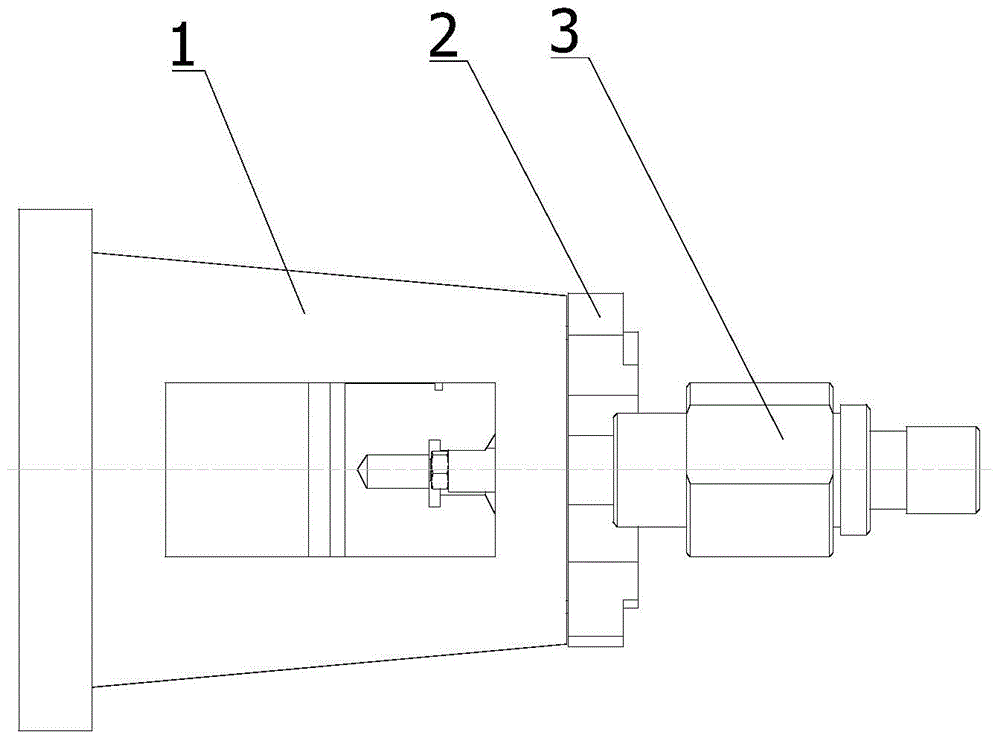

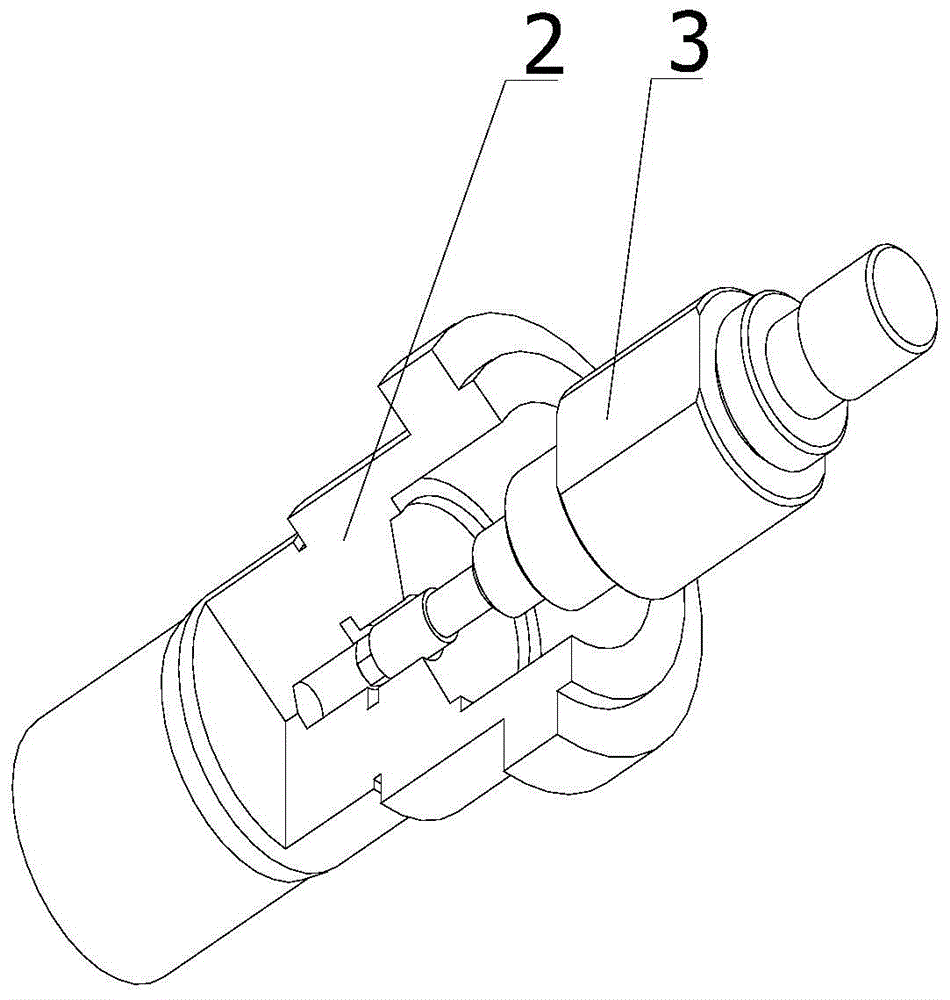

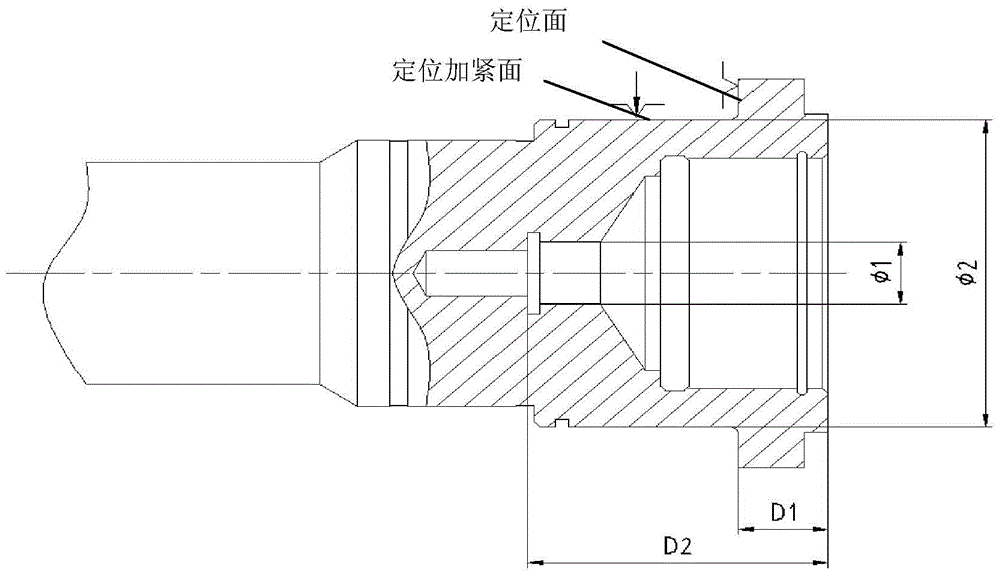

Rotary grinding machine chuck connection structure

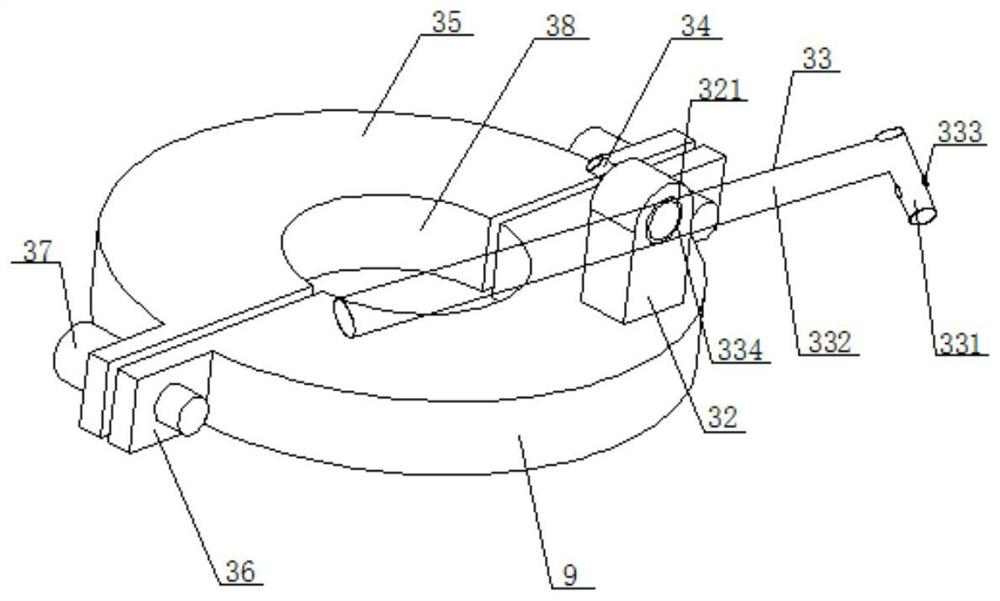

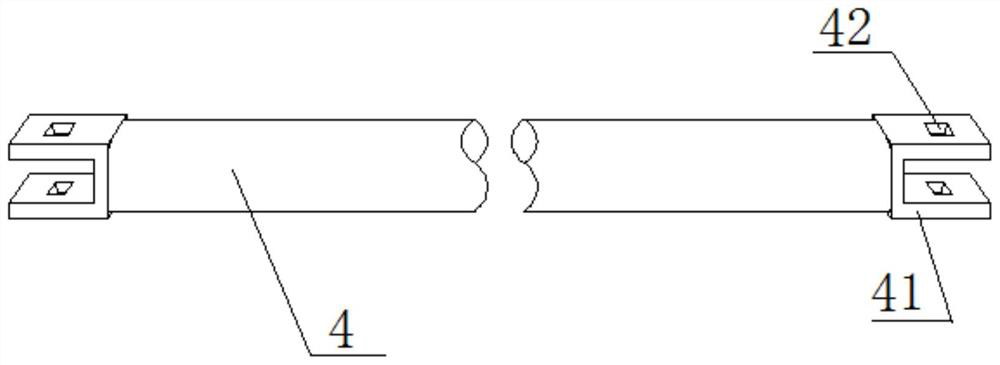

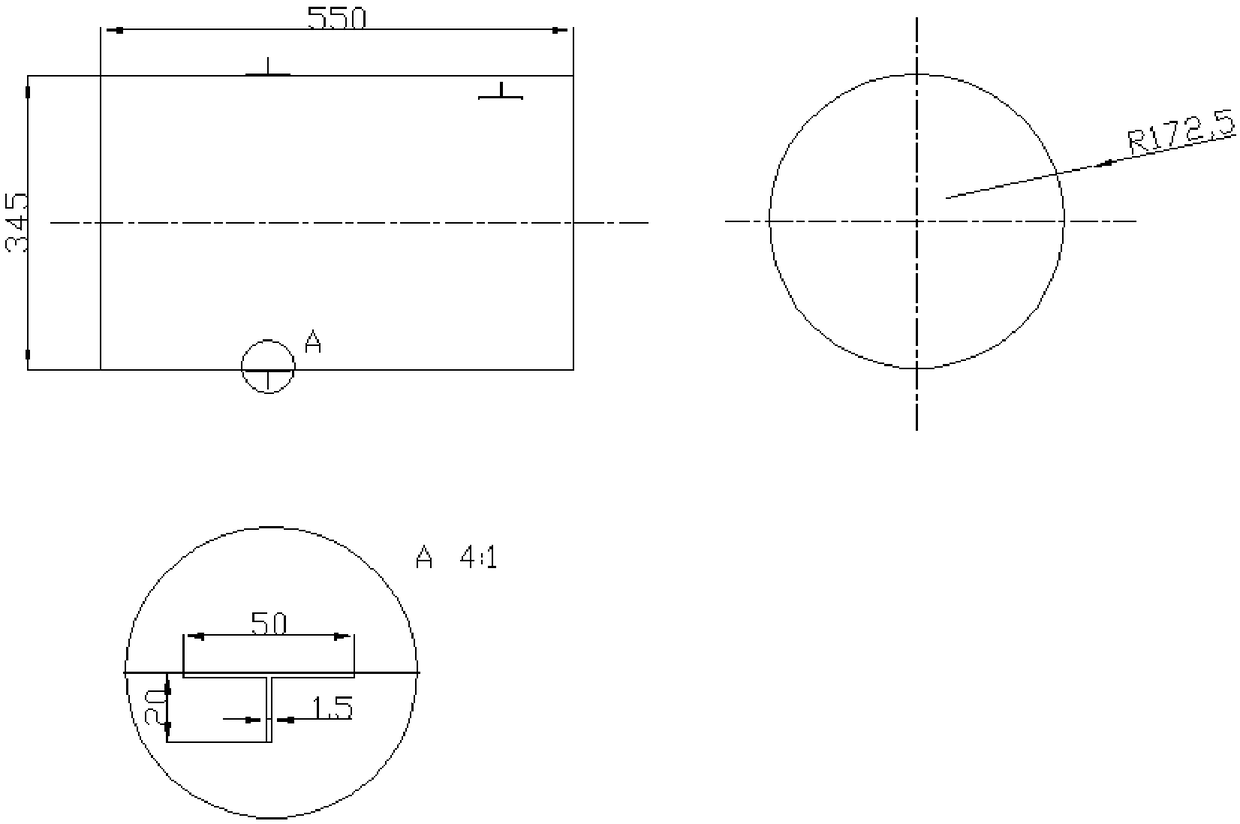

InactiveCN103447948AEasy to install and disassembleImprove work efficiencyGrinding work supportsDisadvantageSupport surface

The invention discloses a rotary grinding machine chuck connection structure, and aims at solving the disadvantages that the current grinding machine chuck is inconvenient in clamping and detaching of components and has low working efficiency, and the components in the clamping and detaching processes are likely to impact a grinding machine. The rotary grinding machine chuck connection structure comprises a base and a chuck seat, wherein the chuck seat is connected with a chuck body; the base is provided with an arc supporting surface, the chuck seat is provided with an arc connection surface, the arc connection surface is provided with an arc slide rail, the arc supporting surface is provided with an arc sliding chute, the arc slide rail is connected with the interior of the arc sliding chute, the front side face of the arc slide rail is a limiting face, the limiting face of the slide rail is provided with a limiting slot, and the side face of the lower part of the limiting slot is a locking slope; the base is connected with a limiting column, the front end face of the limiting column is provided with a limiting head, the front end face of the limiting head is propped against the bottom of the limiting slot in a matching manner, a limiting slope is arranged on the limiting head, and the limiting slope is propped against the locking slope in the matching manner, and the front end face of the limiting column below the limiting head is propped against the limiting surface below the limiting slot in the matching manner.

Owner:张满九

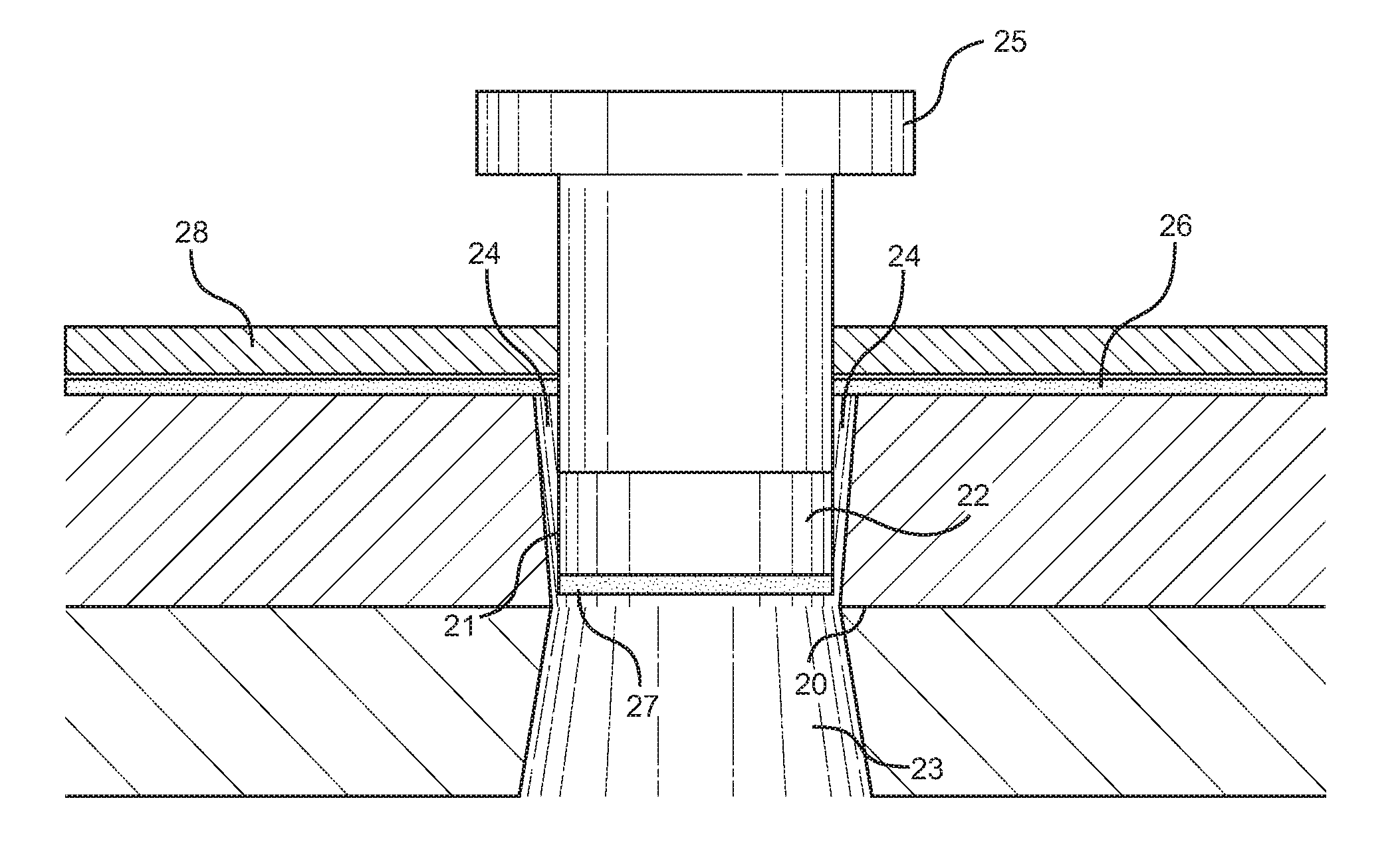

Stamping Slug Retention Recess and Method

Provided is a die trim section with a recess adapted to retain slugs in a stamping process. The recess may be added to existing die inserts via wire EDM, conventional surface grinding or other suitable methods. The recess extends a distance greater than the die trim punch stroke and the cross-sectional area of the recess decreases along the height of the recess.

Owner:COOPER JR DONALD

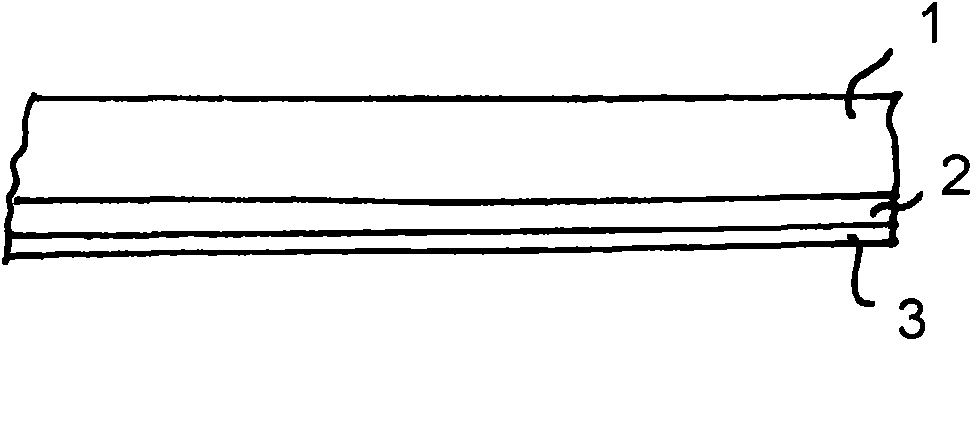

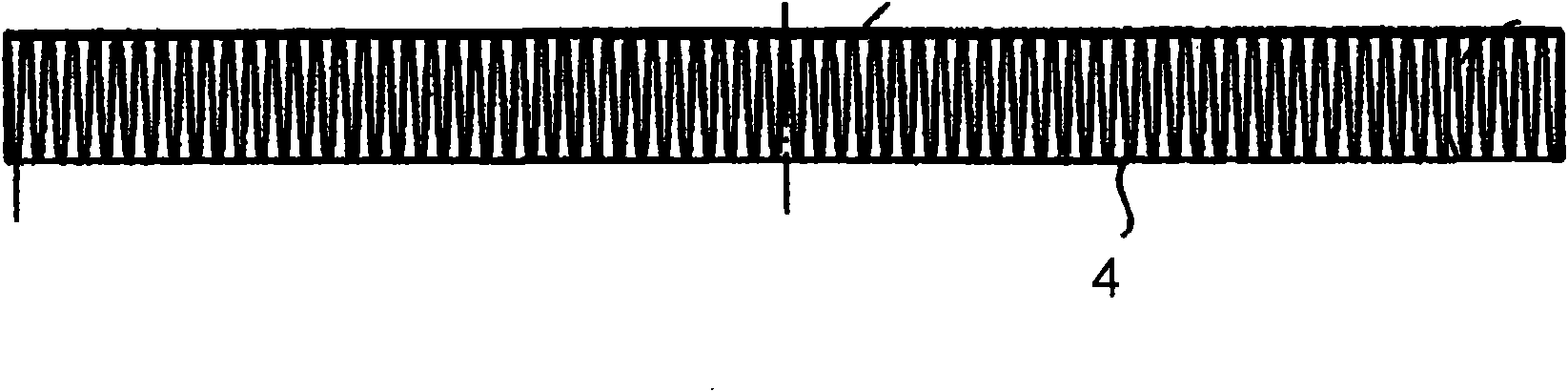

Layer for use in a hepa filter element

ActiveCN101622047AIncrease elasticityElasticity can be reduced or improved without fiberglassDispersed particle filtrationSynthetic resin layered productsGlass fiberHEPA

The invention relates to a layer for use in a HEPA filter element. Said layer comprises a first support layer (1) for stabilization which contains polypropylene fibers, and a second deposition layer (2) which contains polypropylene fibers, wherein the polypropylene fibers of the deposition layer (2) are at least partially electrostatically charged, and wherein the support layer (1) and the deposition layer (2) are constructed as nonwoven material which is at least partially free of glass fiber. The layer according to the invention can be easily pleated while having excellent filter efficiency.

Owner:CARL FREUDENBERG KG

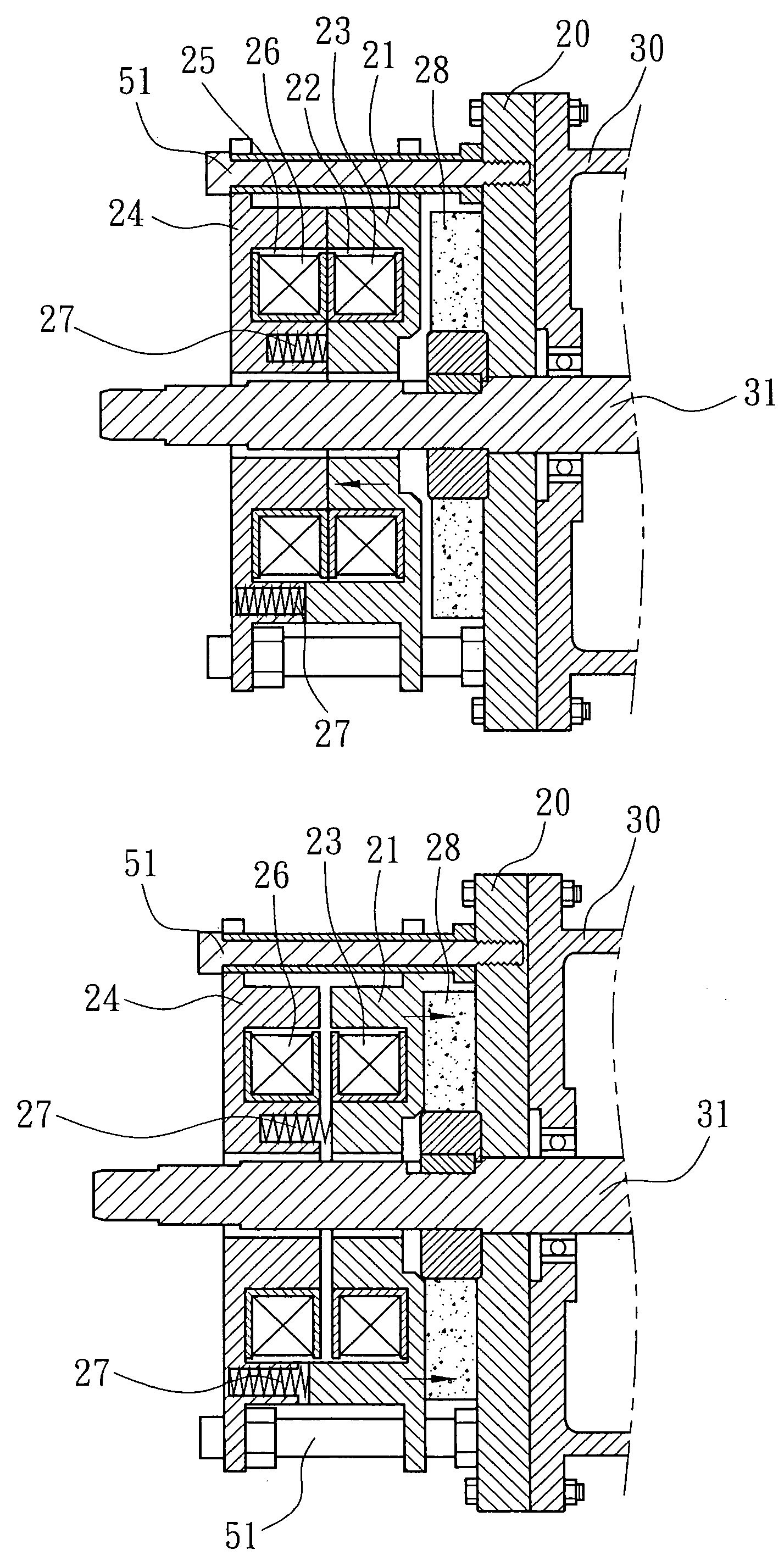

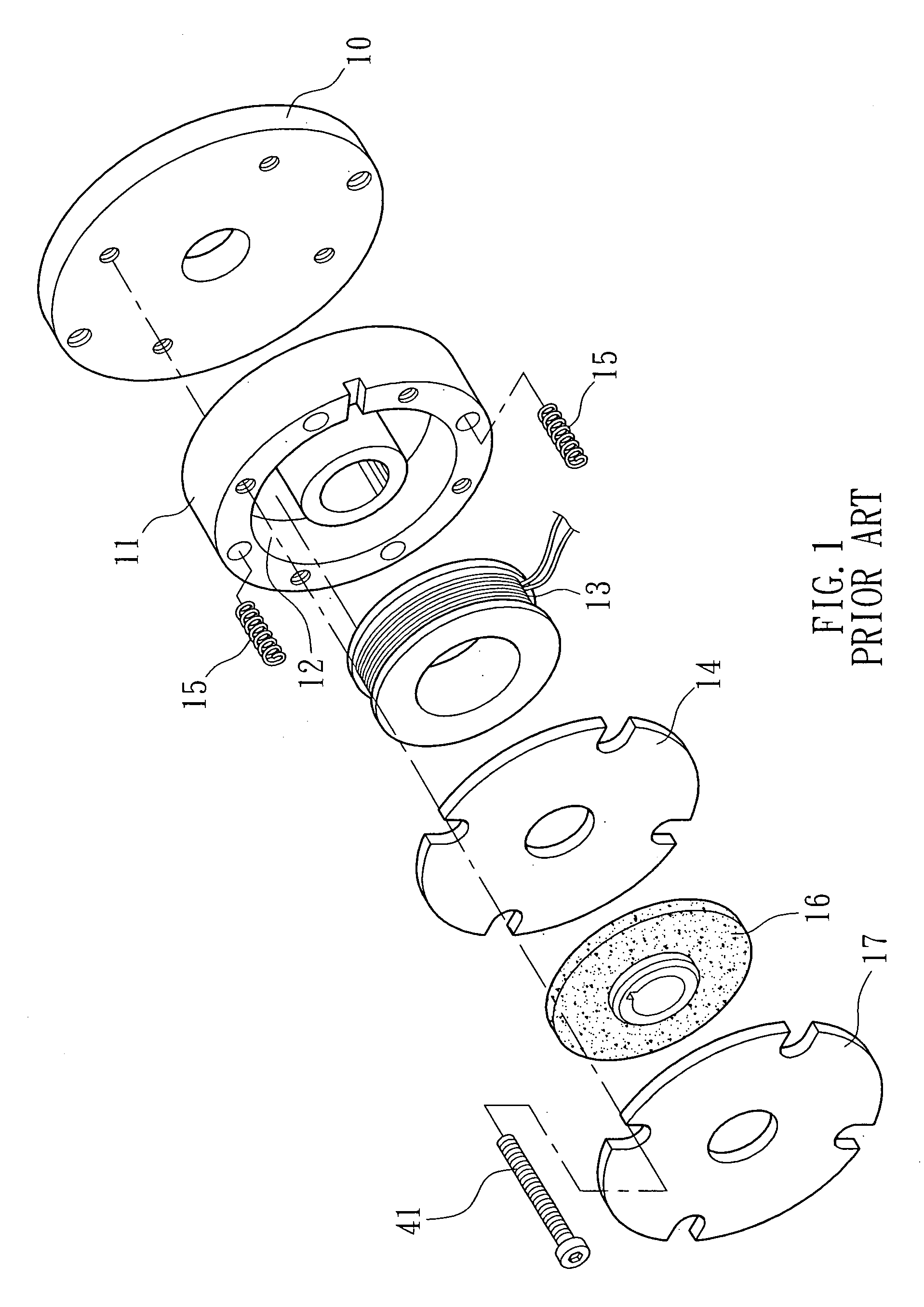

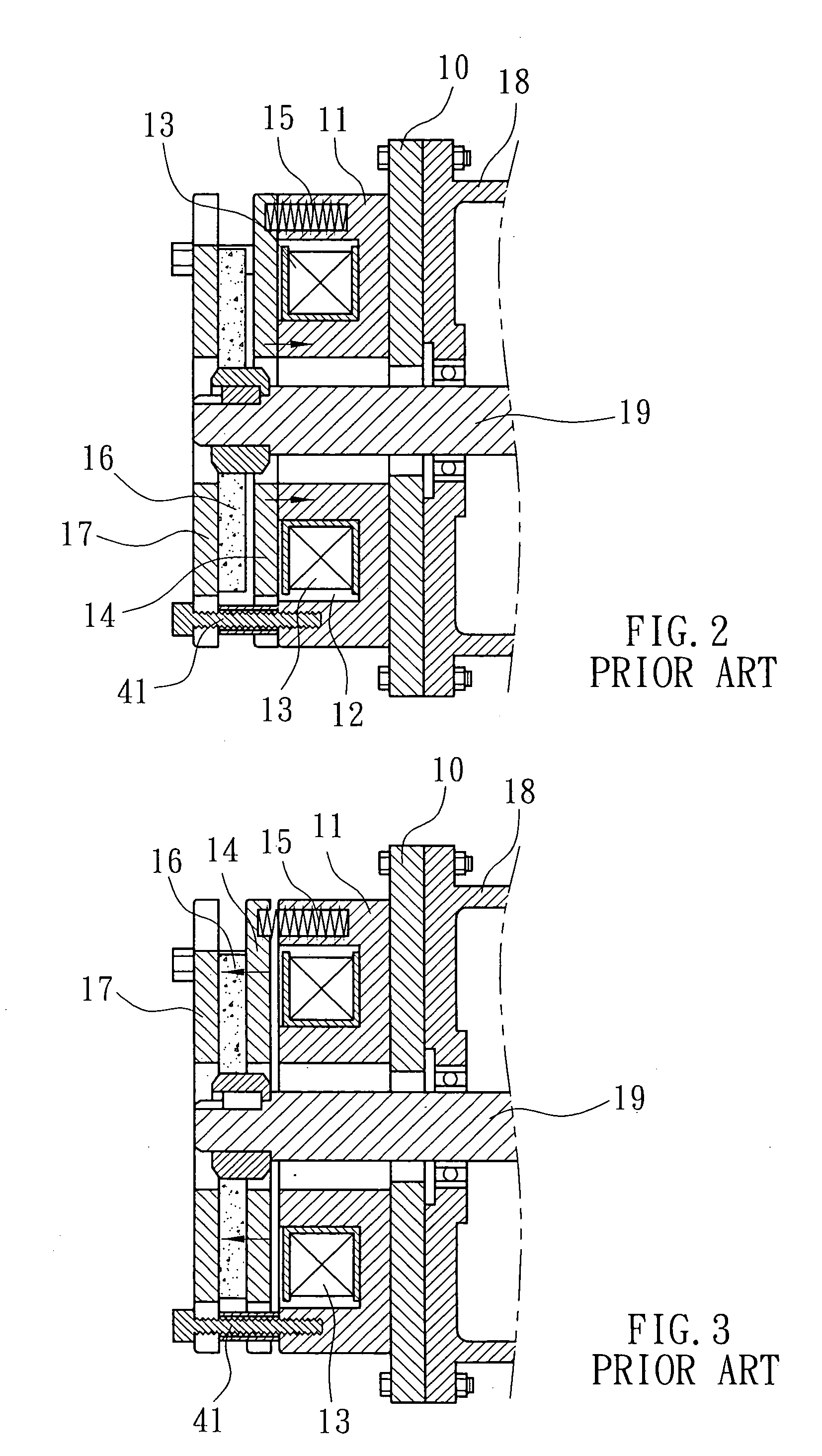

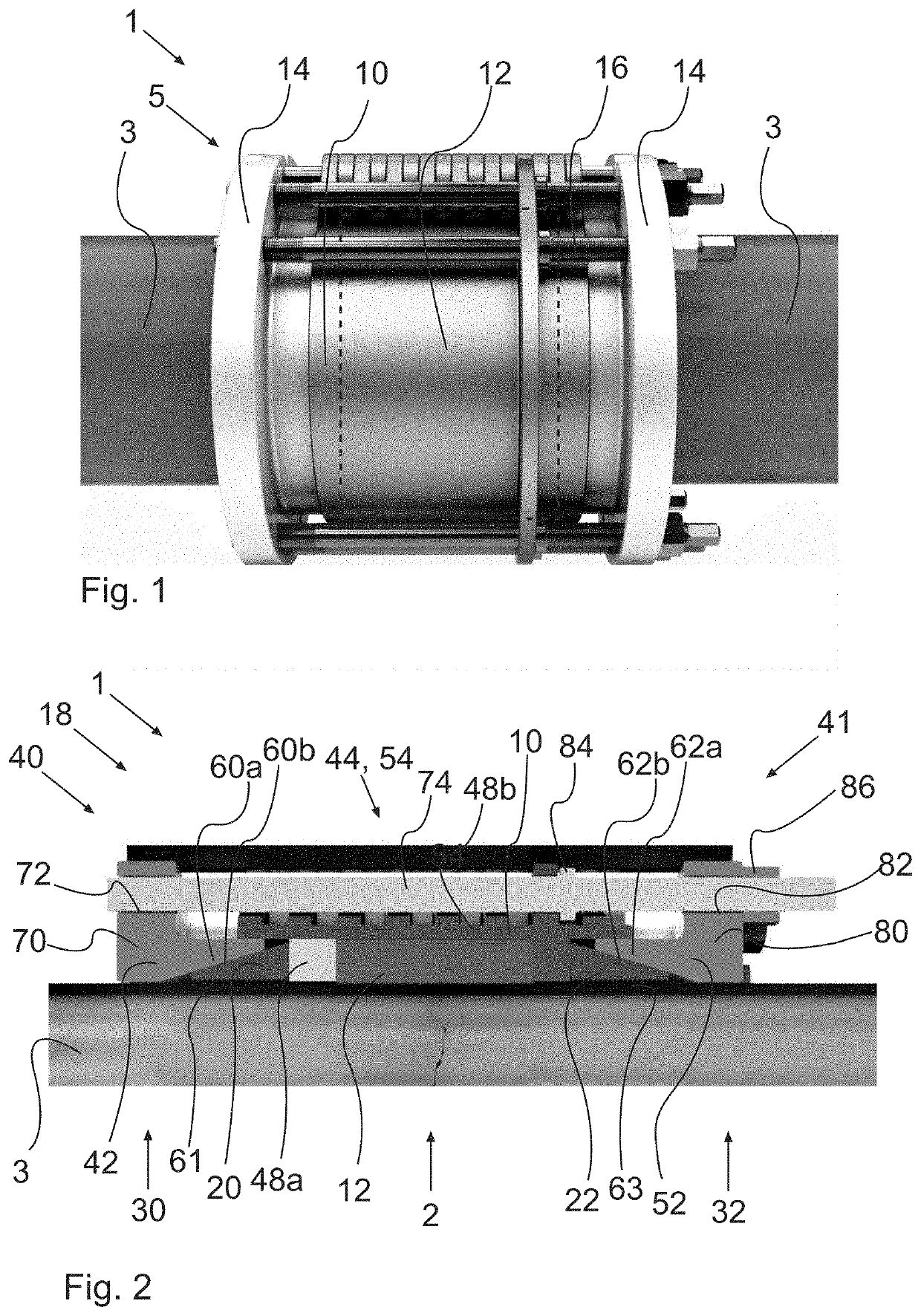

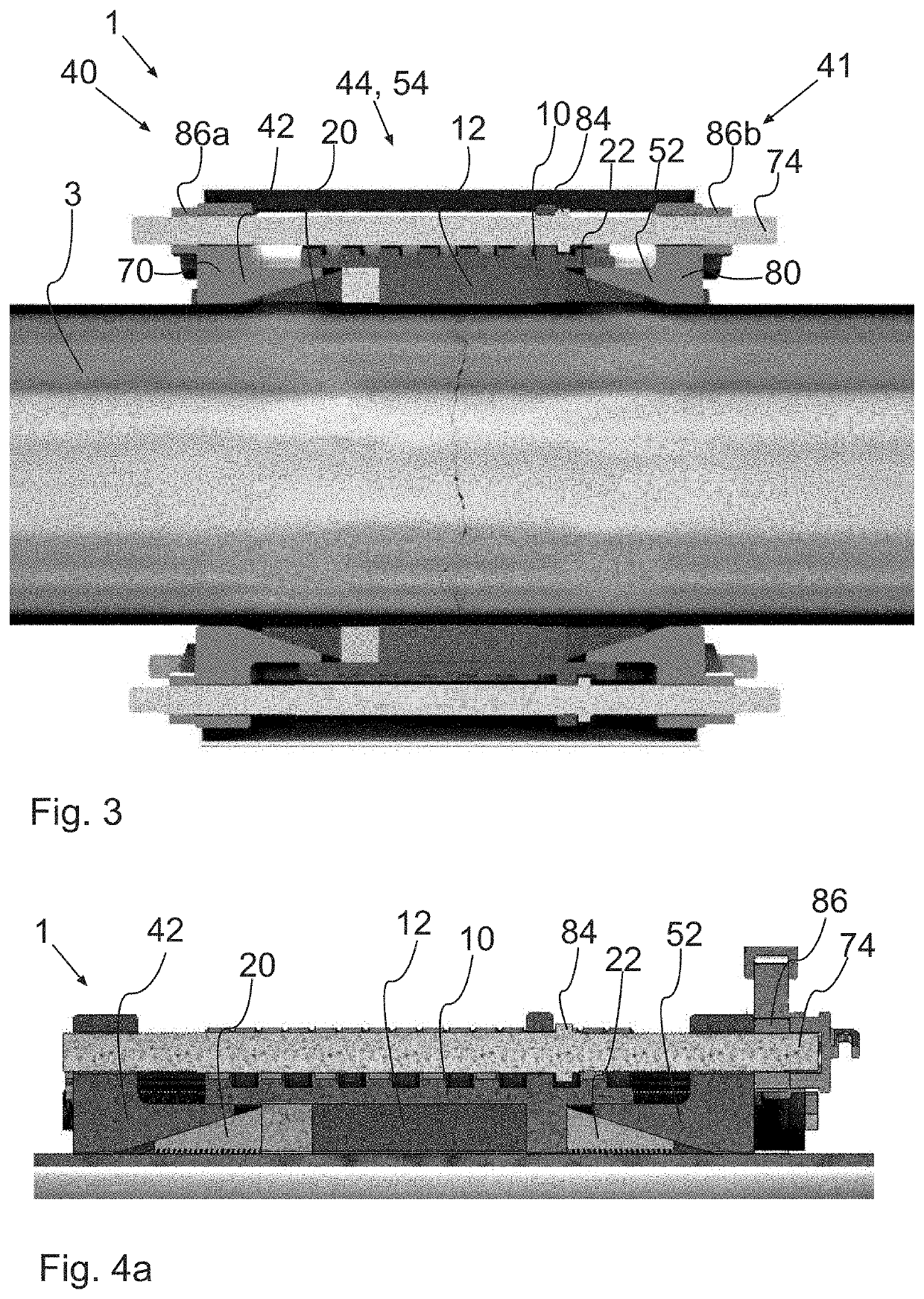

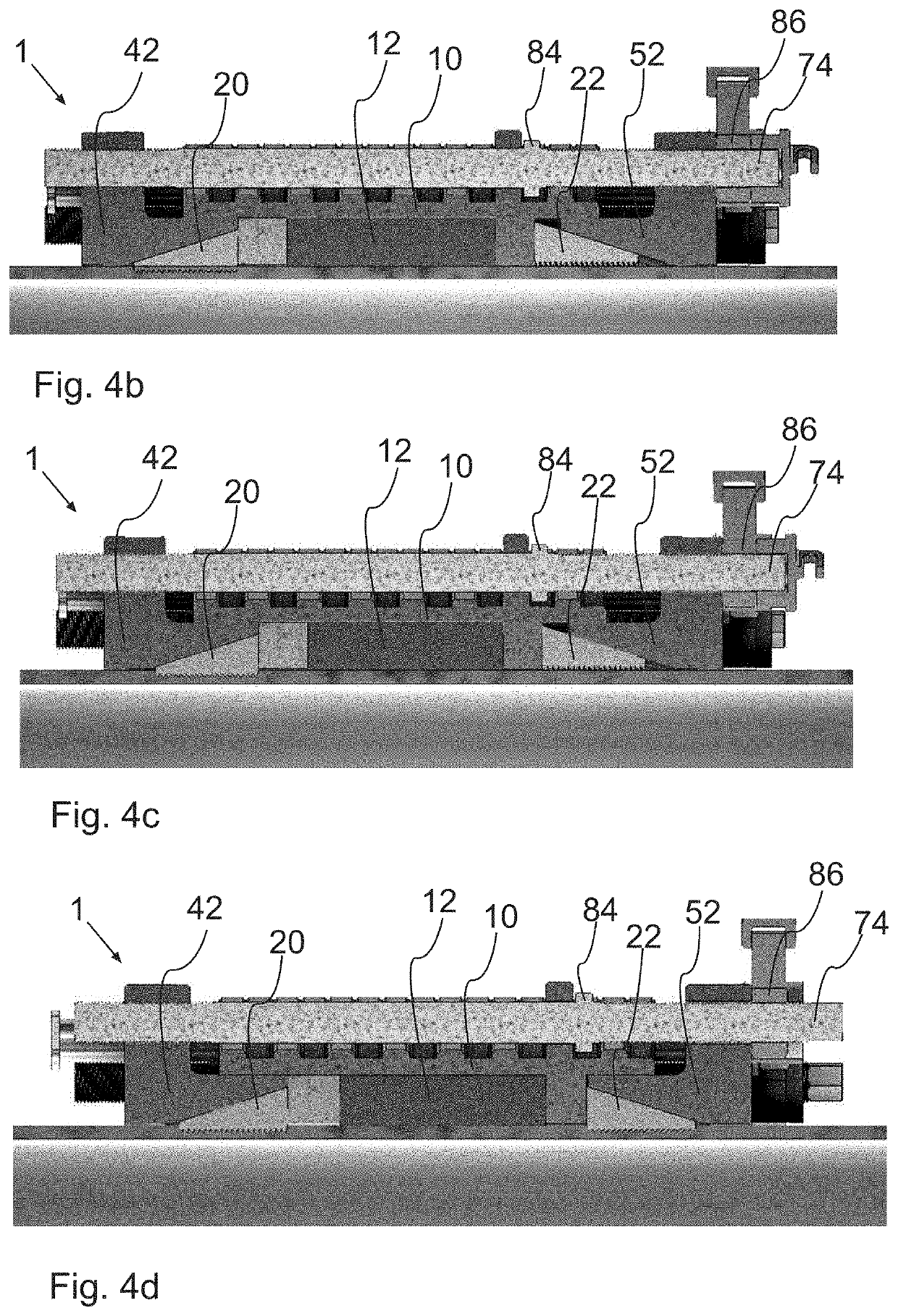

Motor brake

InactiveUS20100133052A1Easy to useAvoid damage to partsElectrodynamic brake systemsMechanical energy handlingControl theoryBrake lining

A motor brake includes a locating plate affixed to a motor around the motor shaft, an outer panel connected to the locating plate with screws, a brake lining affixed to the locating plate, an inner panel movable along the screws between the brake lining and the outer panel, spring members connected between the inner panel and the outer panel for forcing the inner panel against the brake lining to stop the shaft of the motor from rotation, and two windings respectively mounted in the inner panel and the outer panel for attracting each other to move the inner panel away from the brake lining for allowing rotation of the motor shaft when electrically connected.

Owner:WEI TA CHUEN

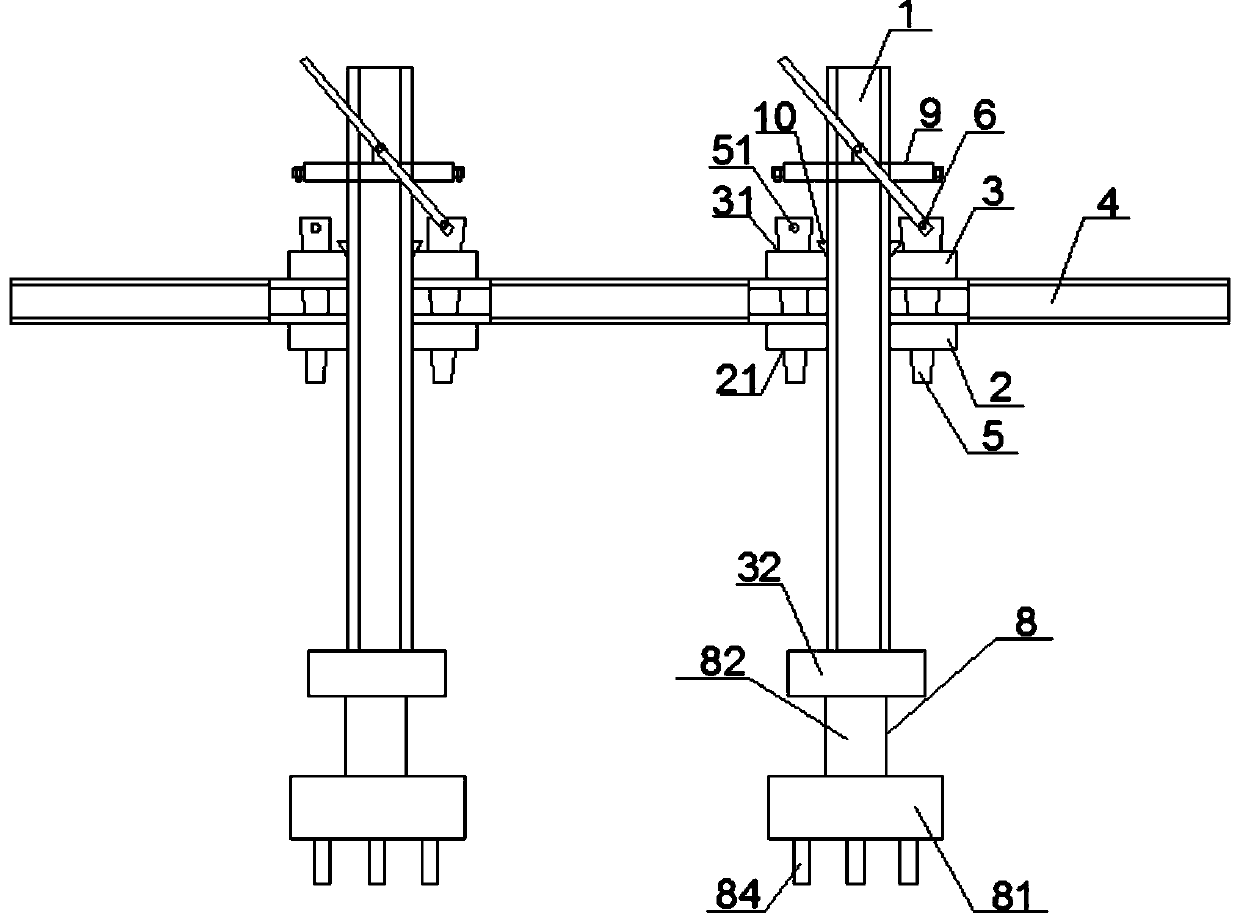

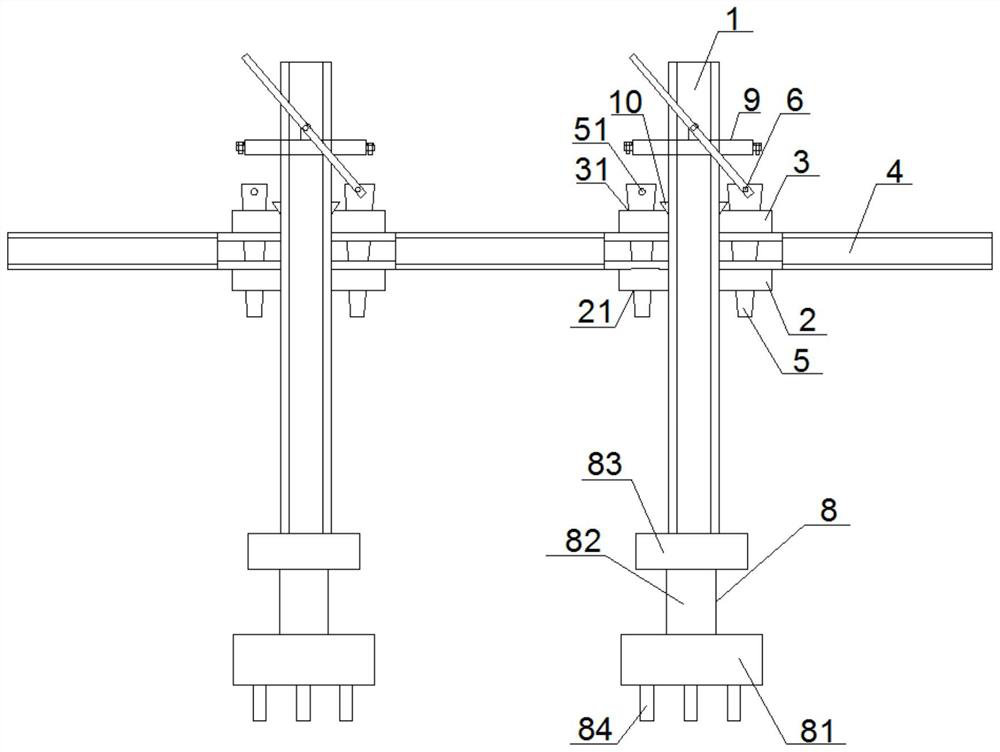

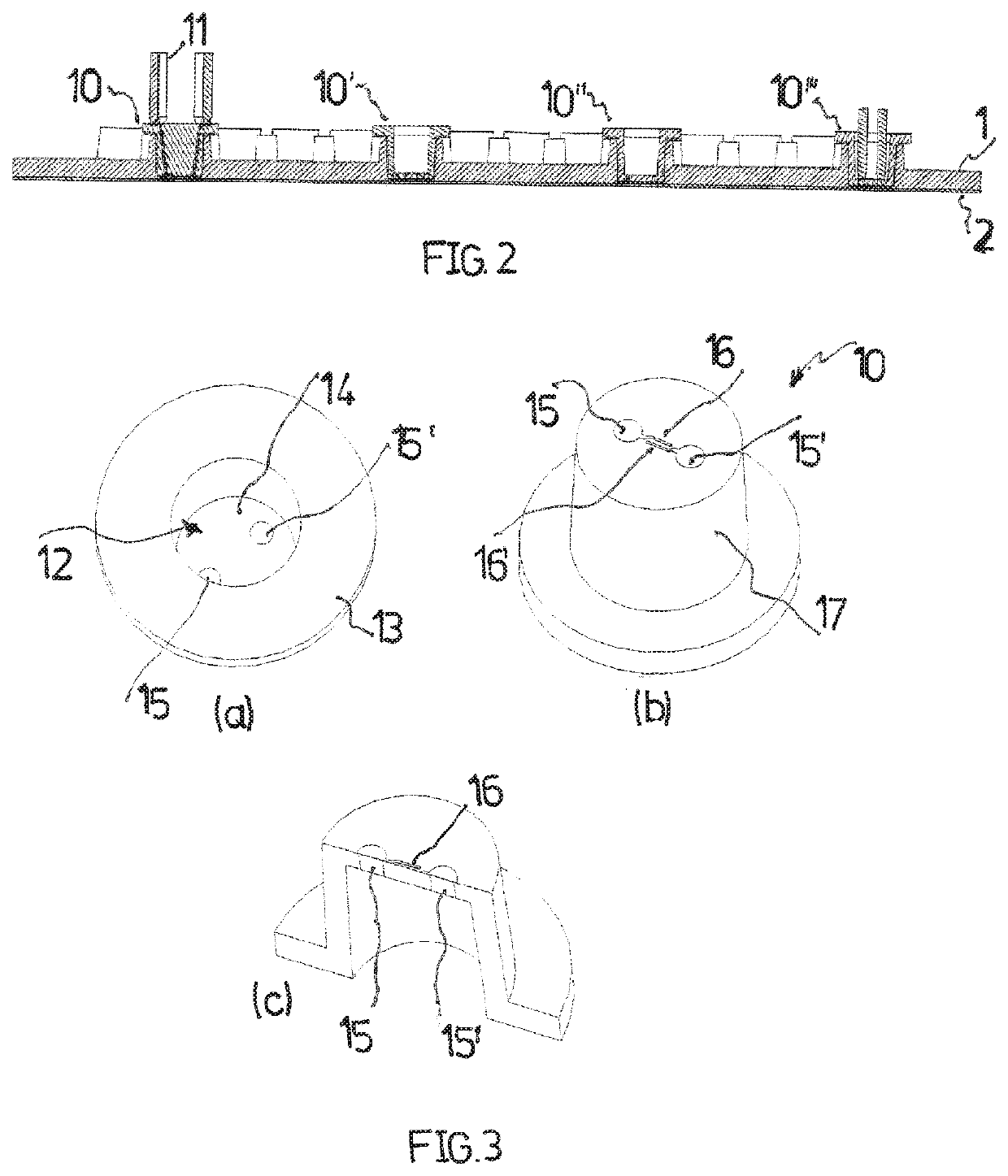

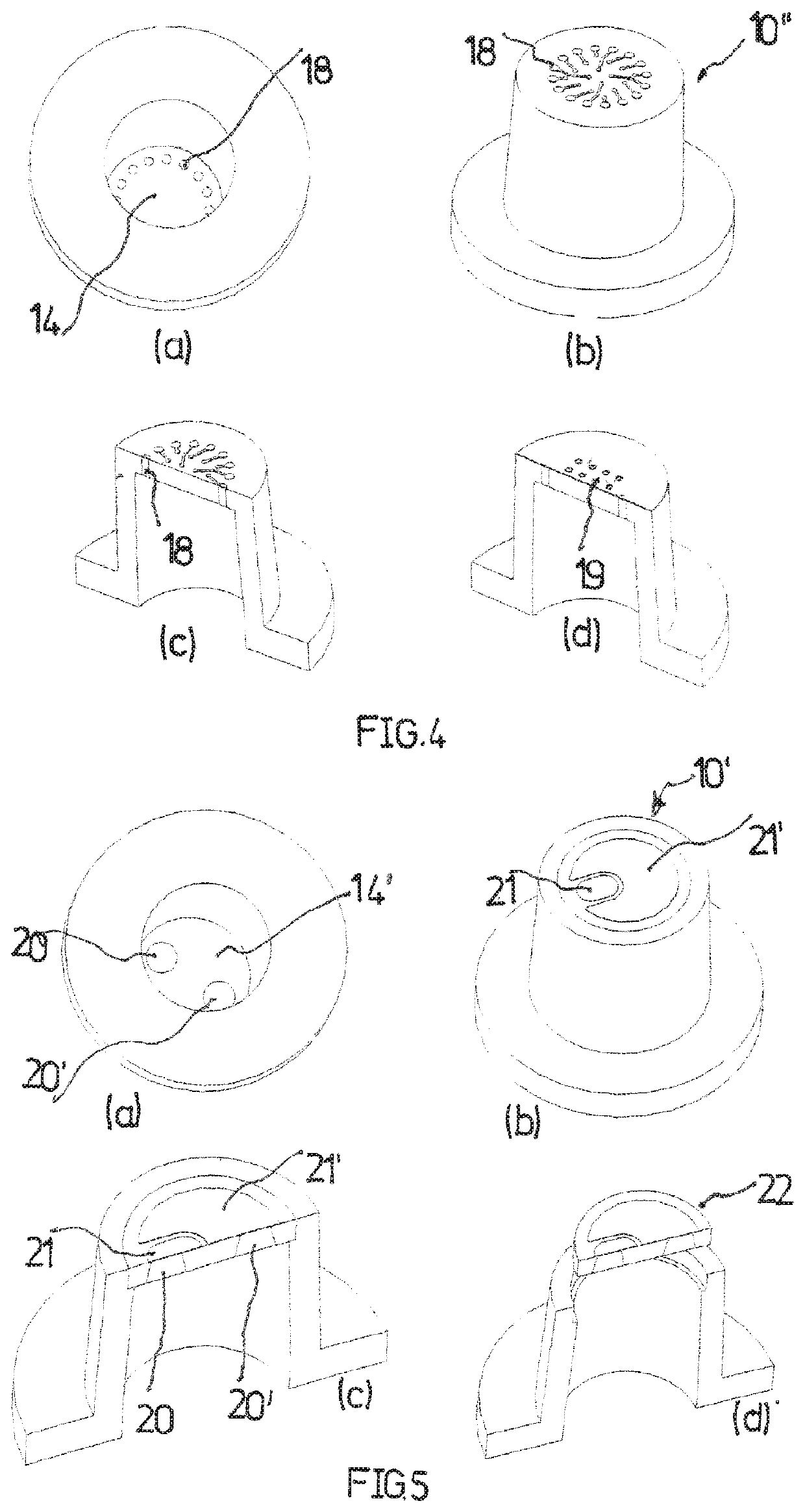

Ring lock scaffold with two fixed discs

ActiveCN110409778AAvoid the inconvenience of disassemblyAvoid damage to partsScaffold connectionsEngineeringBearing capacity

The invention discloses a ring lock scaffold with two fixed discs. The ring lock scaffold with the two fixed discs comprises vertical rods, cross rods, inclined rods and trapezoid bolts, wherein fixedring locks and movable ring locks are arranged on the vertical rods; trapezoid inserting slots a and trapezoid inserting slots b are formed in the fixed ring locks and the movable ring locks; meanwhile, trapezoid inserting slots c and trapezoid inserting slots are formed in the cross rods and the inclined rods; through the cooperation of the trapezoid bolts, the trapezoid inserting slots a, the trapezoid inserting slots b, the trapezoid inserting slots c and the trapezoid inserting slots, the cross rods and the inclined rods are fixed between the fixed ring locks and the movable ring locks; and through the combined action of the movable ring locks and the fixed ring locks, the cross rods and the inclined rods are fixed, so that the occurrence of the phenomena that the joints between the cross rods and the inclined rods as well as between the cross rods and the vertical rods are unevenly stressed, the bearing capacity is too small, and the ring lock scaffold is insufficient in stability and easy to shake is avoided; and the vertical rods are further provided with disassembling devices, and the disassembling devices are used for disassembling the trapezoid bolts, so that the problems that the inconvenience in disassembling is caused and parts are damaged since the disassembling operation is carried out by a tool in the prior art are solved.

Owner:浙江维安建筑支护科技有限公司

A disc buckle scaffold with two fixed discs

ActiveCN110409778BAvoid the inconvenience of disassemblyAvoid damage to partsScaffold connectionsStructural engineeringMechanical engineering

The invention discloses a buckle-type scaffolding with two fixed discs, which comprises a vertical pole, a horizontal bar, an oblique pole and a trapezoidal latch, and a fixed disc buckle and a movable disc buckle are arranged on the vertical pole, and the fixed disc buckle and the movable disc buckle There are trapezoidal slots a and trapezoidal slots respectively on the top, and trapezoidal slots c and trapezoidal slots are respectively arranged on the horizontal bar and the inclined bar. The cooperation of the groove c and the trapezoidal slot fixes the crossbar and the oblique rod between the fixed buckle and the movable buckle, and the crossbar and the diagonal rod are fixed through the joint action of the movable buckle and the fixed buckle, so as to avoid the crossbar and the The connection between the oblique rod and the vertical rod is unevenly stressed and the bearing capacity is too small, resulting in insufficient stability of the buckle-type scaffolding, which is prone to shaking. The vertical rod is also equipped with a dismantling device, which disassembles the trapezoidal bolt, avoiding the traditional The use of tools to disassemble brings the problems of inconvenient disassembly and damaged parts.

Owner:浙江维安建筑支护科技有限公司

Exhaust manifold heat dissipation cover coupling device for thermal stress and vibration deflection

ActiveUS11408323B2Increased durabilityAvoid damage to partsSilencing apparatusMachines/enginesThermal dilatationThermodynamics

An exhaust manifold heat dissipation cover coupling device for thermal stress and vibration deflection is proposed. The device has a function of preventing wear of a heat dissipation cover to couple an exhaust manifold heat dissipation cover, the device being able to improve the durability of various parts including a heat dissipation cover by attenuating multi-directional vibration that is transmitted from an exhaust manifold when the heat dissipation cover is installed outside the exhaust manifold, being able to prevent damage to parts due to thermal stress by flexibly coping with thermal deformation such as thermal contraction or thermal expansion even if the thermal deformation is generated by high-temperature heat transmitted from the exhaust manifold, and being able to prevent frictional damage of the heat dissipation cover due to friction by a component that slides to attenuate vibration.

Owner:HYUNDAI MOTOR CO LTD +2

Curbstone and stop

InactiveUS20180127927A1Avoid damage to partsReduce distanceSingle unit pavingsPaving gutters/kerbsEngineeringMechanical engineering

Owner:PROFILBETON

Rotatable grinding machine chuck connection structure

InactiveCN103447948BAppropriate angle rangeImprove locking effectGrinding work supportsEngineeringSupport surface

The invention discloses a rotary grinding machine chuck connection structure, and aims at solving the disadvantages that the current grinding machine chuck is inconvenient in clamping and detaching of components and has low working efficiency, and the components in the clamping and detaching processes are likely to impact a grinding machine. The rotary grinding machine chuck connection structure comprises a base and a chuck seat, wherein the chuck seat is connected with a chuck body; the base is provided with an arc supporting surface, the chuck seat is provided with an arc connection surface, the arc connection surface is provided with an arc slide rail, the arc supporting surface is provided with an arc sliding chute, the arc slide rail is connected with the interior of the arc sliding chute, the front side face of the arc slide rail is a limiting face, the limiting face of the slide rail is provided with a limiting slot, and the side face of the lower part of the limiting slot is a locking slope; the base is connected with a limiting column, the front end face of the limiting column is provided with a limiting head, the front end face of the limiting head is propped against the bottom of the limiting slot in a matching manner, a limiting slope is arranged on the limiting head, and the limiting slope is propped against the locking slope in the matching manner, and the front end face of the limiting column below the limiting head is propped against the limiting surface below the limiting slot in the matching manner.

Owner:张满九

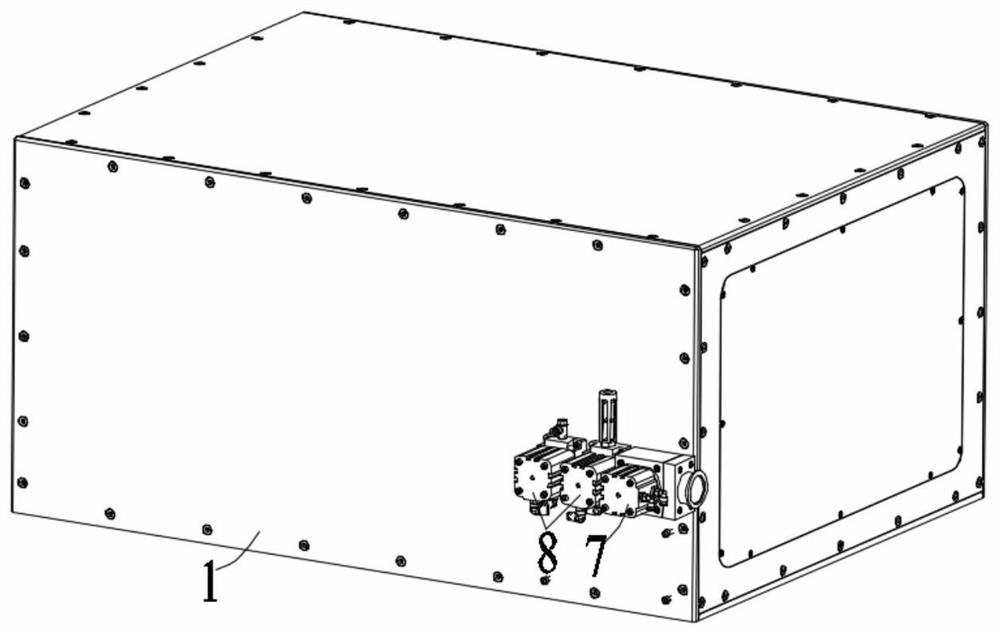

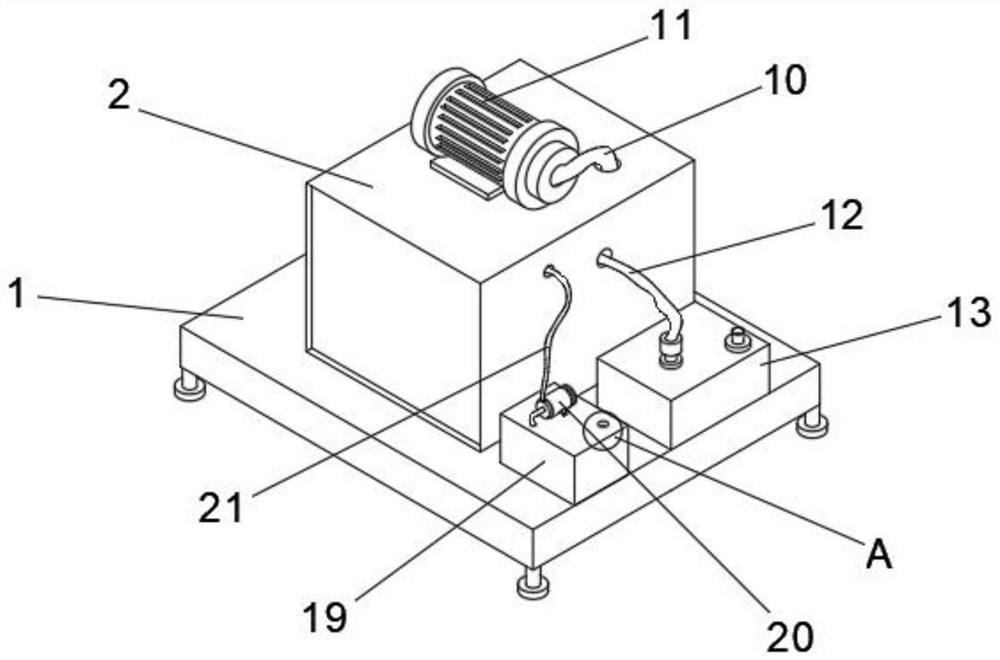

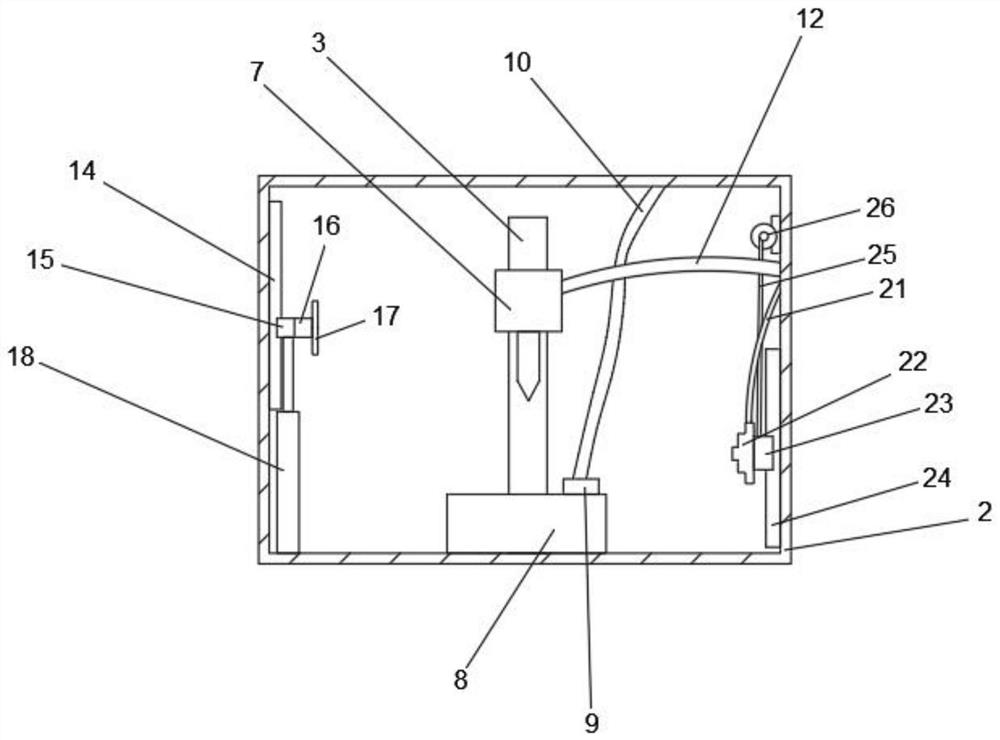

Multifunctional vacuum dispensing device

ActiveCN114682437AImprove sealingExtended service lifeLiquid surface applicatorsFinal product manufactureEngineeringWorkbench

The invention discloses a multifunctional vacuum dispensing device which comprises a sealing bin, a rack, a dispensing valve and a workbench, the sealing bin is installed on the rack, and an extraction opening and two air inlets are formed in the outer surface of one side of a vacuum bin body; the inner wall of the end, close to the interior of the vacuum bin body, of each of the extraction opening and the air inlet is provided with a flange part extending inwards in the radial direction, a first flange plate is embedded into the extraction opening, a second flange plate is embedded into the air inlet, and a weighing mechanism is arranged on the workbench. The weighing mechanism comprises a base installed on the workbench, a movable carrier plate installed on the upper portion of the base and a material cup placed on the upper surface of the movable carrier plate, the two ends of the movable carrier plate correspond to the two end faces of the base in a one-to-one mode, and the movable carrier plate is connected with the two end faces of the base in a matched mode through a guide part and a movable part, so that the movable carrier plate can move up and down relative to the base. According to the invention, the weight of liquid in a vacuum environment is measured, and the problem that electronic weighing equipment in a vacuum bin body is difficult to use is solved.

Owner:SUZHOU TERUITE ROBOT CO LTD

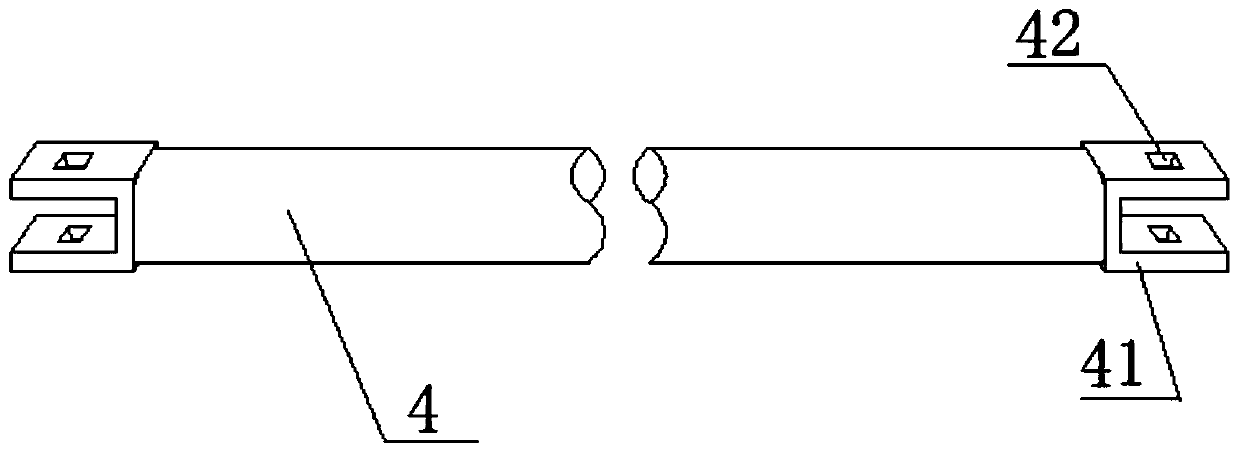

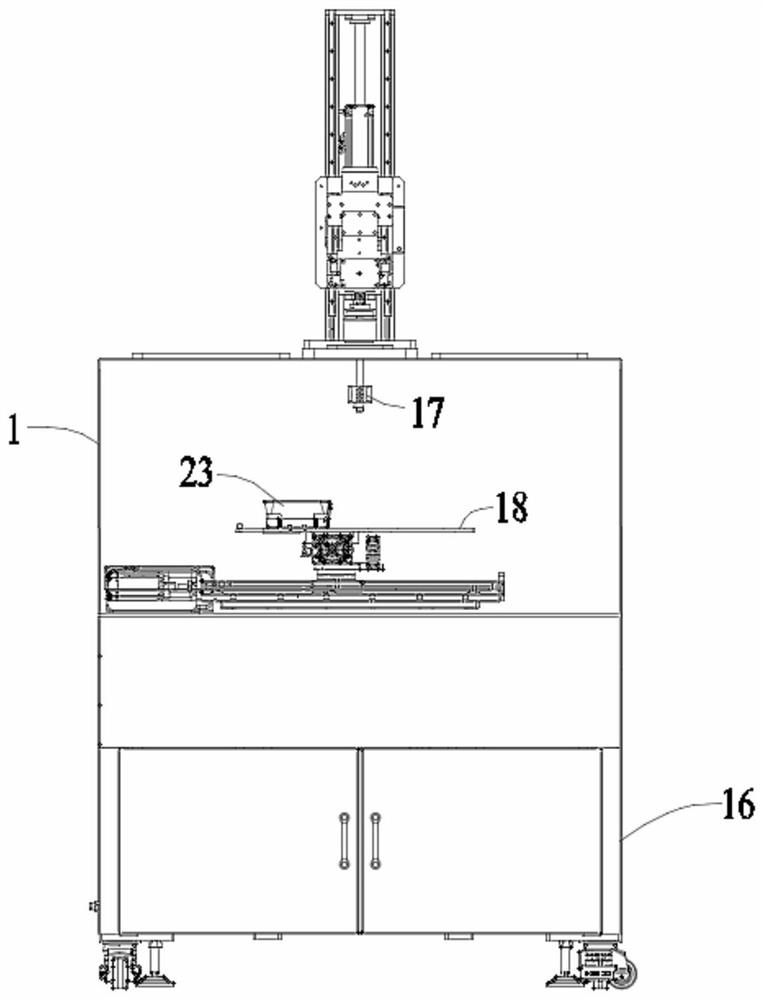

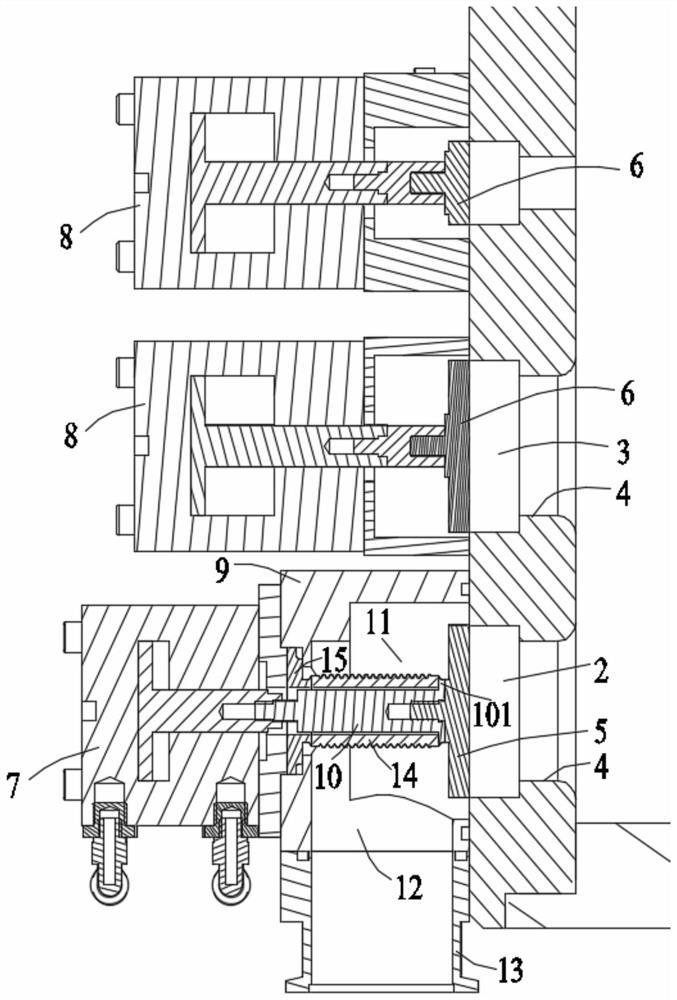

Material returning and feeding forming mechanism for special-shaped parts and method thereof

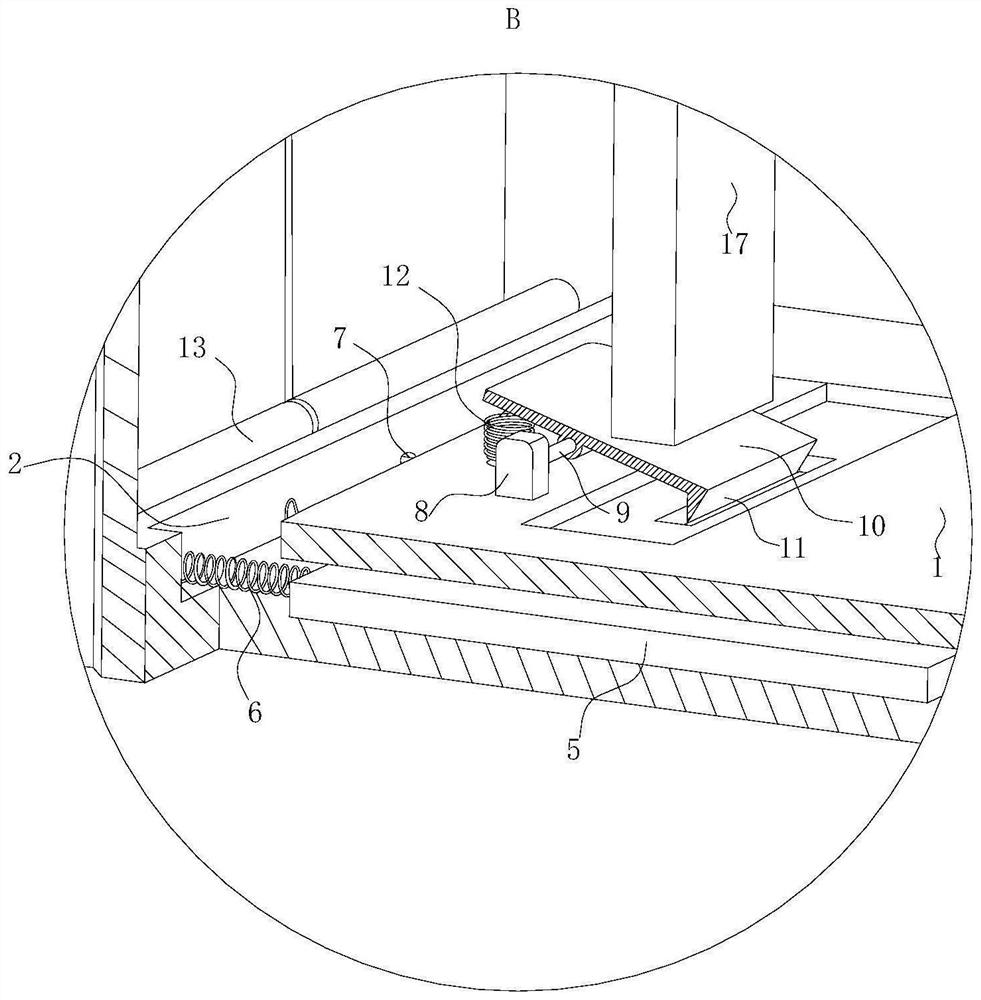

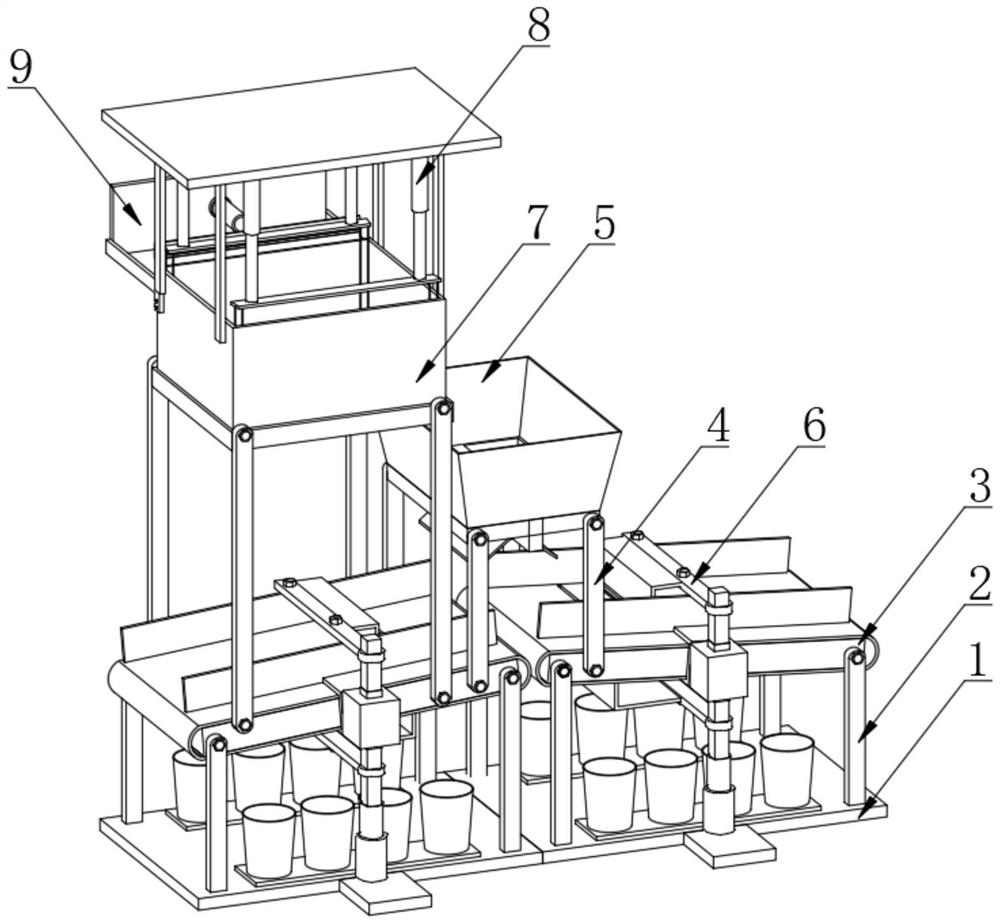

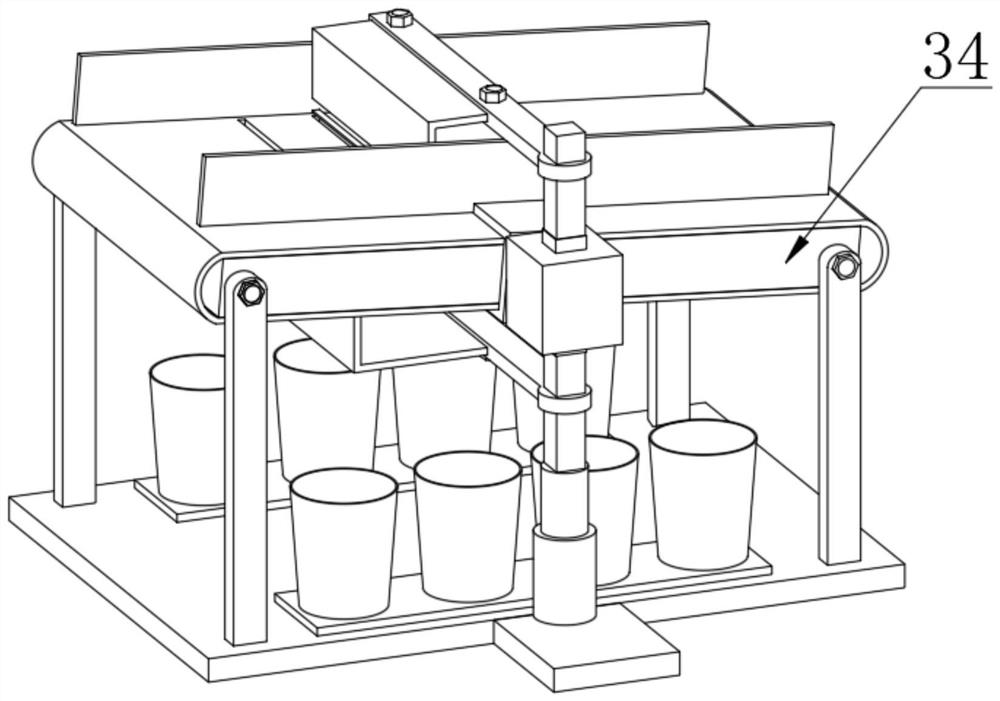

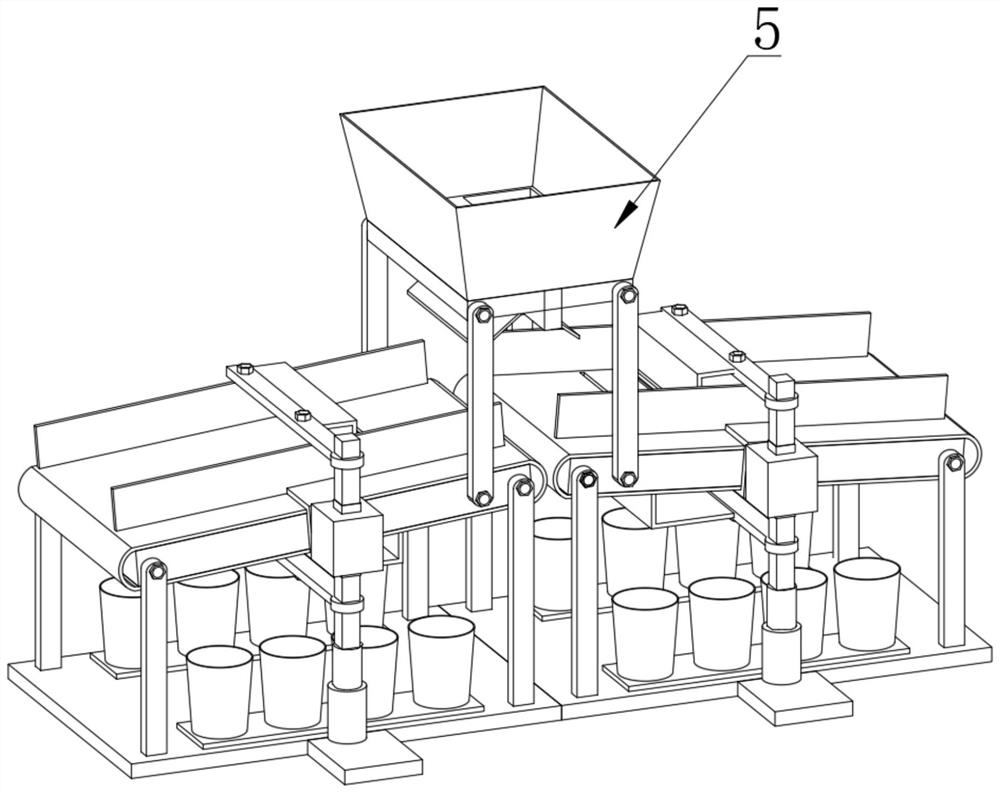

PendingCN111151647AGuaranteed machining dimensional accuracyAvoid damage to partsMetal-working feeding devicesPositioning devicesDimensional precisionManufacturing engineering

The invention discloses a material returning and feeding forming mechanism for special-shaped parts. The material returning and feeding forming mechanism comprises a forming mechanism for carrying outroll extrusion forming on a blank workpiece according to a preset angle, and a double-station orientation / material returning mechanism for carrying out orientation, material returning and station conversion on the blank workpiece; and the operation end of the double-station orientation / material returning mechanism corresponds to the machining end of the forming mechanism, and the double-station orientation / material returning mechanism is used for conveying the grabbed blank workpiece into the forming mechanism and used for exiting the formed workpiece machined and formed in the forming mechanism. A grabbing station and a material returning station are switched on the double-station orientation / material returning mechanism, the grabbing station and the material returning station are matched with the forming mechanism, the feeding or material returning function is provided for the forming mechanism, the problem that the parts are damaged due to the fact that the parts are clamped many times is avoided, and the machining size precision of the parts is guaranteed.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

Clamp device and method for repairing a damaged part of a pipe section, and use of such clamp device

PendingUS20220146036A1Prevent leakagePrevent degradationPipe laying and repairPipe elementsStructural engineeringMechanical engineering

A clamp device is for repairing a damaged part of a pipe section. The clamp device has a patch member and a support structure having a clamp body supporting the patch member. The clamp device has a first engagement member configured to engage with a first part of the pipe section and a second engagement member configured to engage with a second part of the pipe section. The clamping device has a first mechanism configured to engage the first engagement member with the first part and compress the patch member at the damaged part, and a second mechanism configured to engage the second engagement member with the second part and induce a compressive force between the first engagement member and the second engagement member.

Owner:IK NORWAY AS

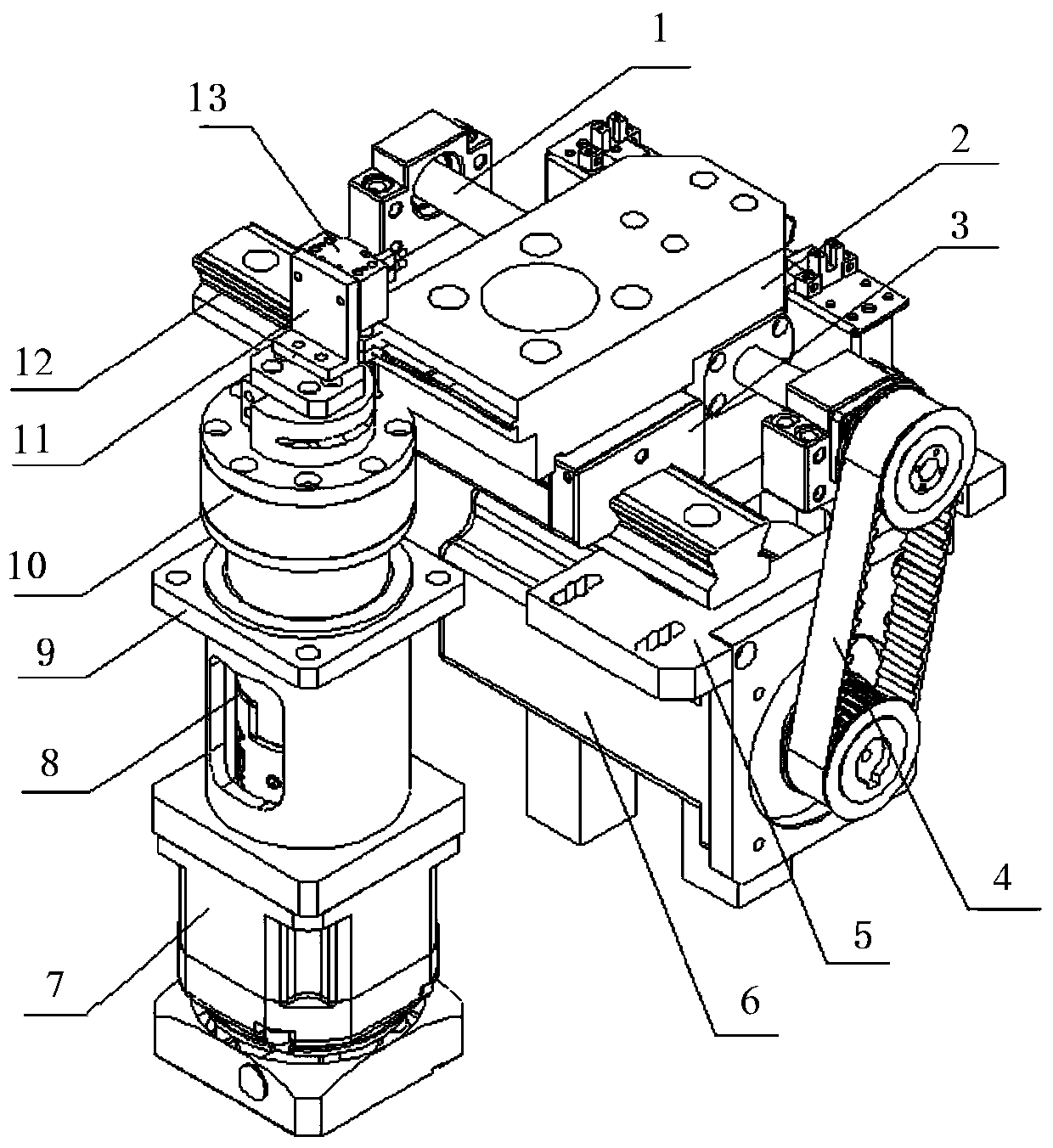

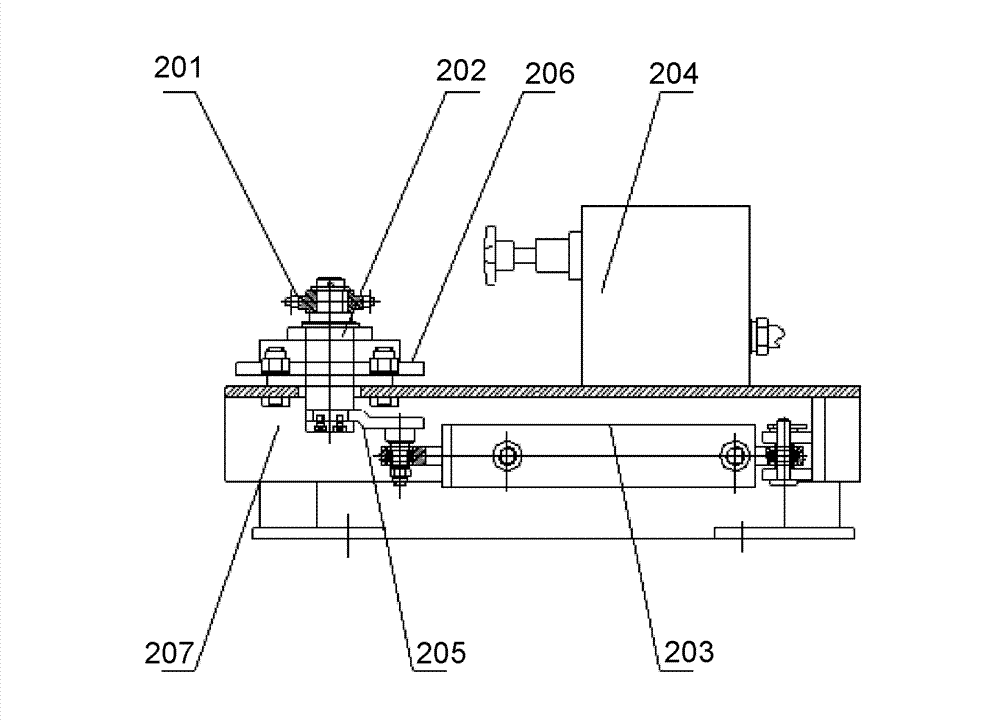

A shaft grinding process method and device for small pores

ActiveCN104275629BEasy to processAvoid damageRevolution surface grinding machinesGrinding work supportsEngineeringTwo step

The invention discloses a technological method and a device for grinding a shaft small hole, which aims at effectively protecting a cutter, greatly prolonging the service life of the cutter, improving the adjusting efficiency, and improving the product quality and production efficiency. The device adopts the technical scheme that the device comprises a sectioning clamp, wherein the sectioning clamp is of a two-step type sleeve tube structure, the interior of the sectioning clamp is fixedly provided with a grinding sample, the grinding sample has the same structure and size with a to-be-processed shaft type part, the contour of the grinding sample is of a three-step type structure, a large end of the grinding sample is provided with a hole along the axial direction, the cutter can extend into the hole, the interior of the hole is provided with a to-be-ground small fine hole, the head of the cutter can extend into the small fine hole in the grinding sample during processing, the inner wall structure of the sectioning clamp is matched with the shape of the grinding sample, the side wall of the grinding sample is provided with a notch along the axial direction, the side wall of the sectioning clamp is provided with an observation window corresponding to the notch of the grinding sample, and the internal structure of the grinding sample and the grinding position of the cutter can be conveniently observed through the notch and the observation window.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

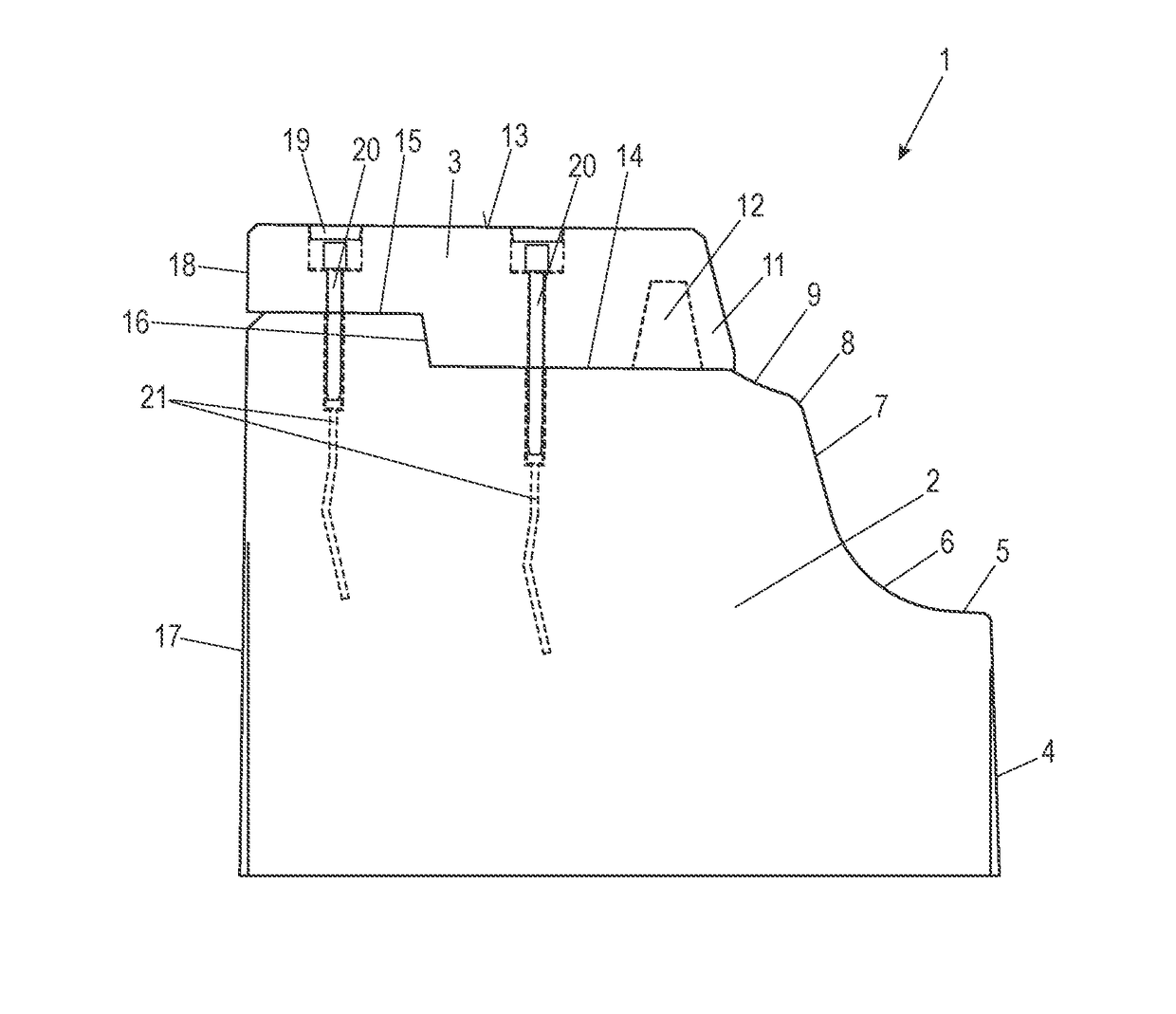

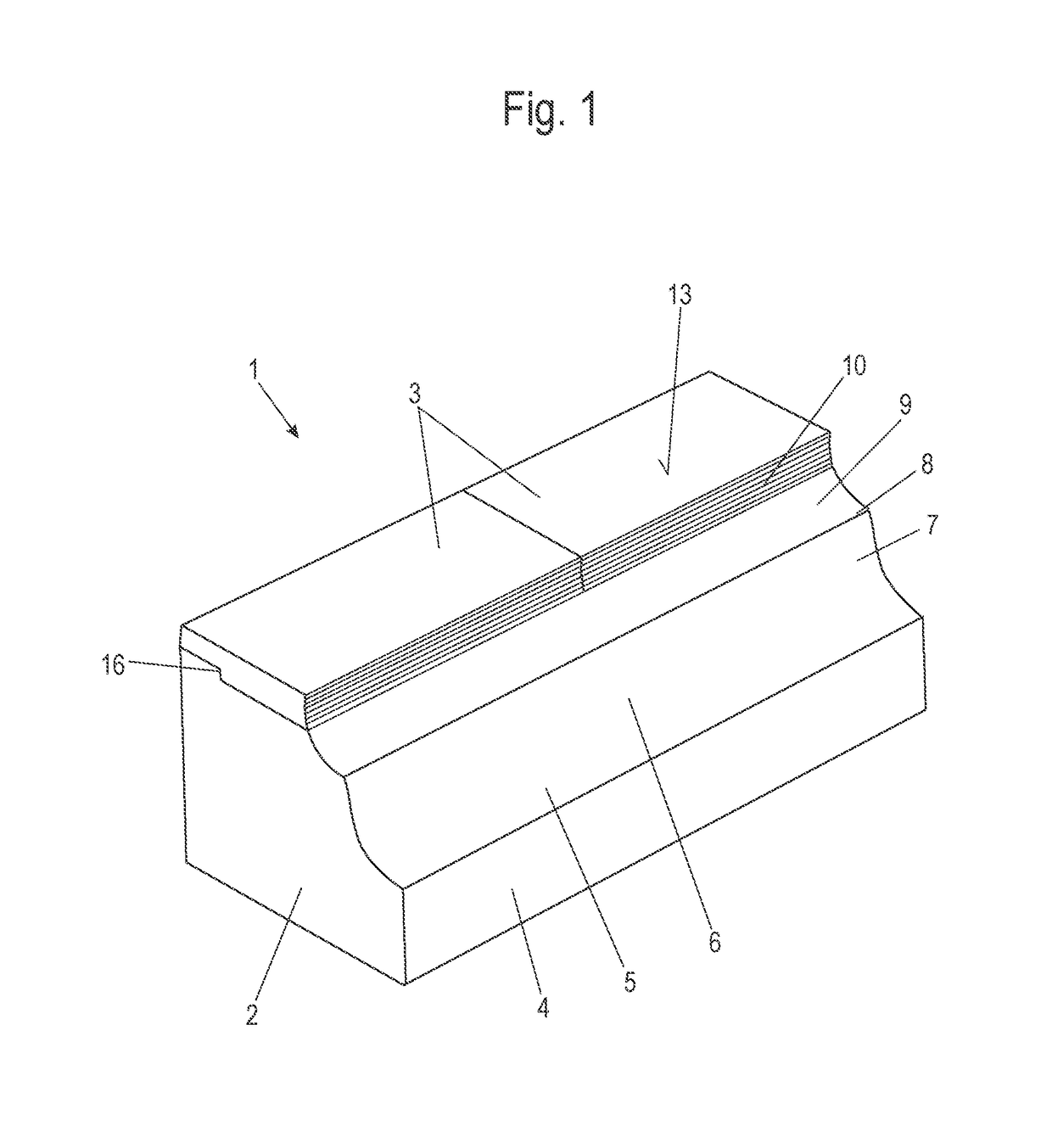

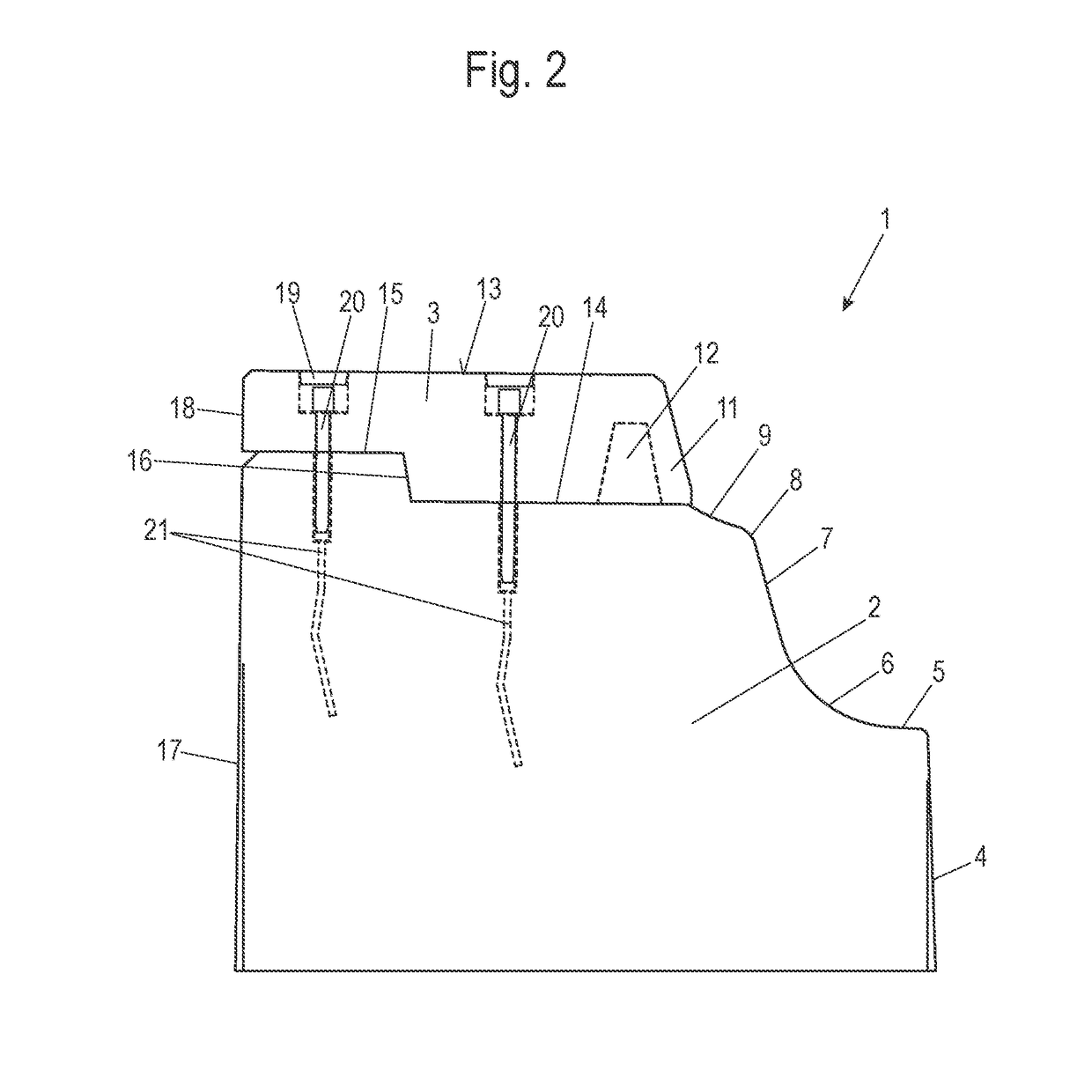

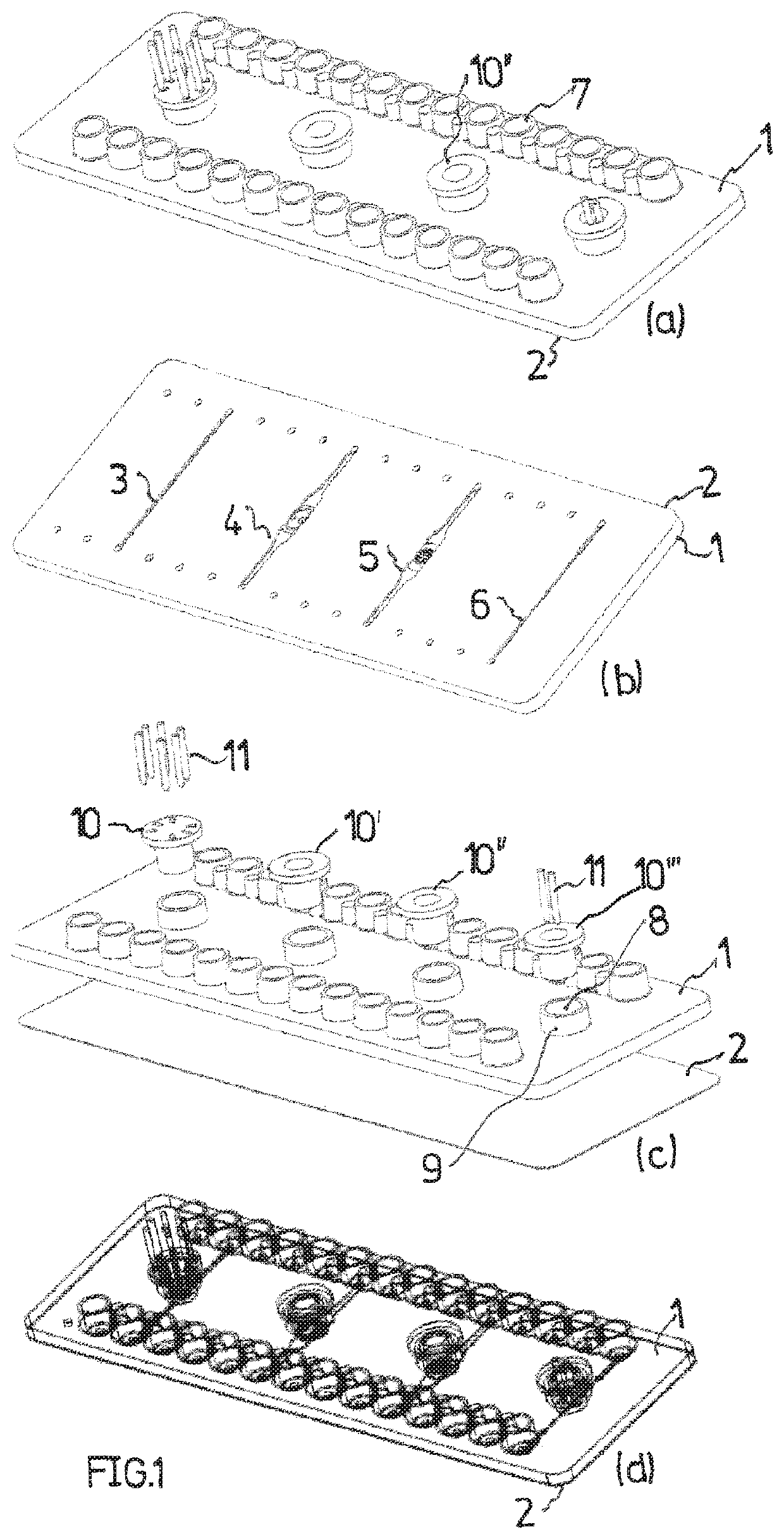

Microfluidic flow cell comprising an integrated electrode, and method for manufacturing same

ActiveUS11433393B2Reduce effortIncreased functional reliabilityLaboratory glasswaresElectrical conductorFlow cell

A microfluidic flow cell including an electrode or sensor device which is located inside the flow cell and from which at least one connecting conductor leads to an externally accessible terminal contact. The electrode or sensor device is arranged on an insulated substrate member. The connecting conductor is embedded in the substrate member. The substrate member can be inserted into an opening in the flow cell such that the electrode or sensor device is placed in the flow cell.

Owner:THINXXS MICROTECHNOLOGY AG

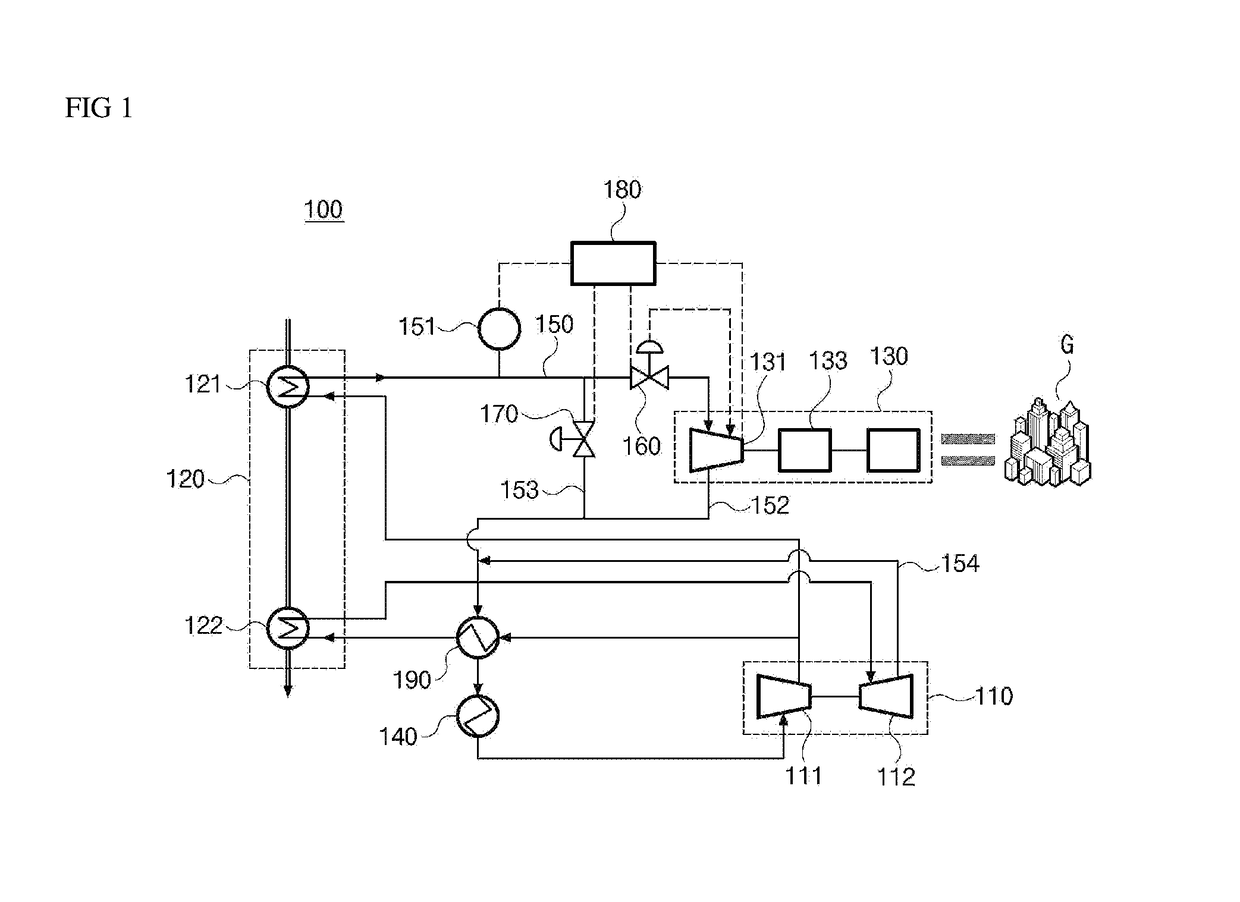

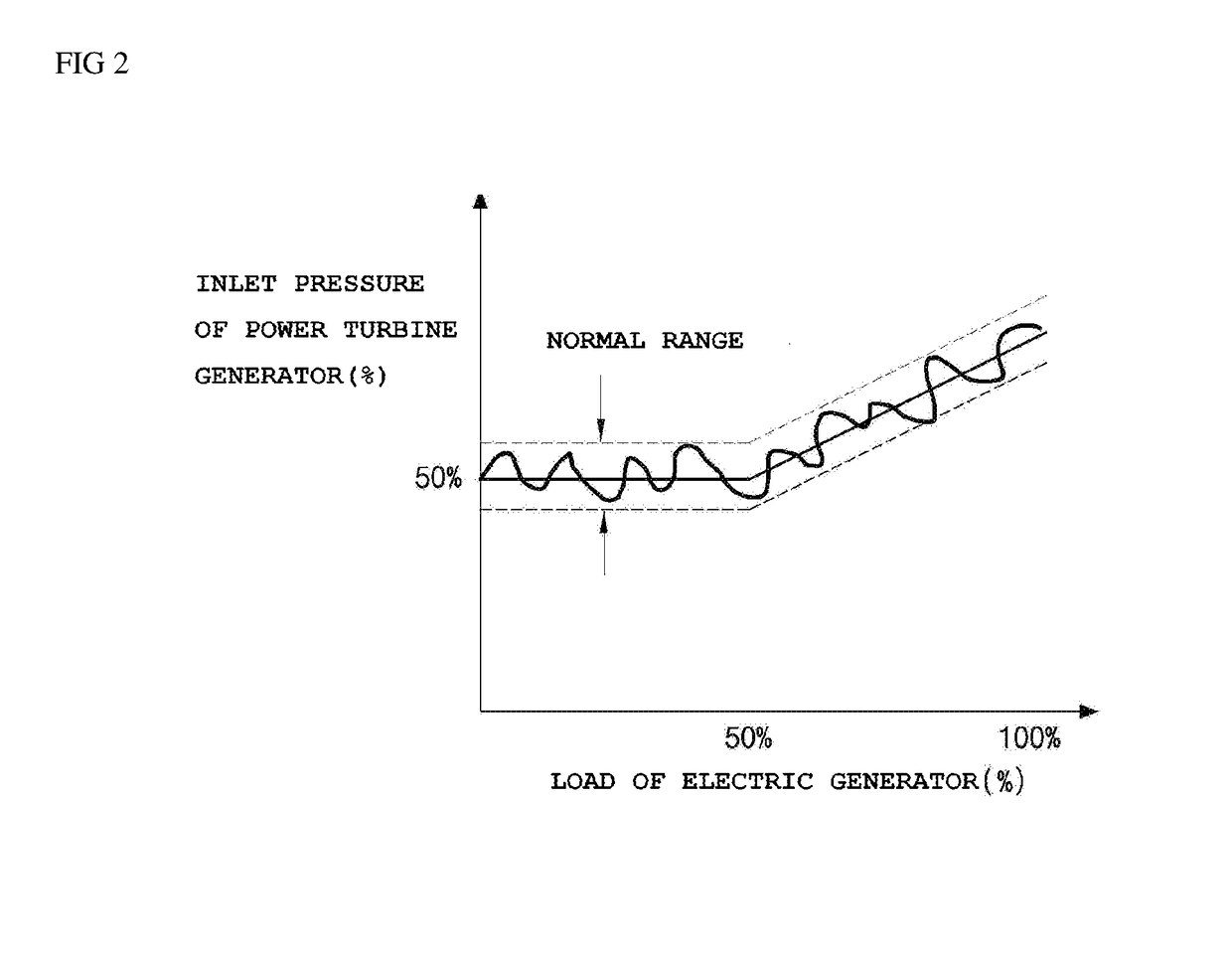

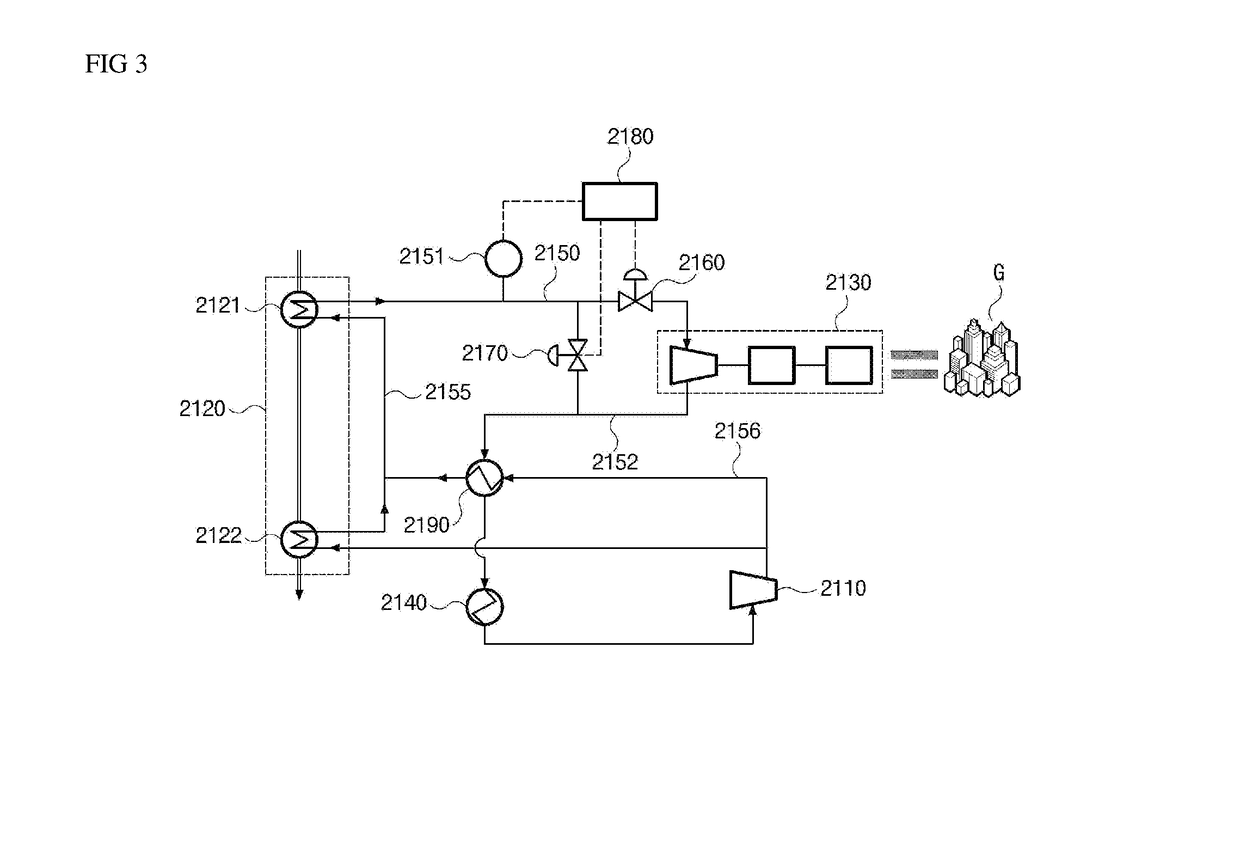

Power plant and method of controlling same

ActiveUS20190048746A1Avoid damagePrevent speedingElectrical storage systemSteam engine plantsElectricityWorking fluid

Disclosed are a power plant that uses a synchronous generator using a working fluid for generation of electric power, and a method of controlling the power plant, the power plant and the control method having an advantage of preventing damage to the power plant during synchronization with an electrical grid. The power plant comprises a pump for compressing a working fluid, a heat exchanger for heat transfer from an external heat source to the working fluid transferred from the pump, and a power turbine generator for generating a rotational force by using the working fluid heated by the heat exchanger, generating electricity using the rotational force, and supplying the electricity to an electrical grid.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

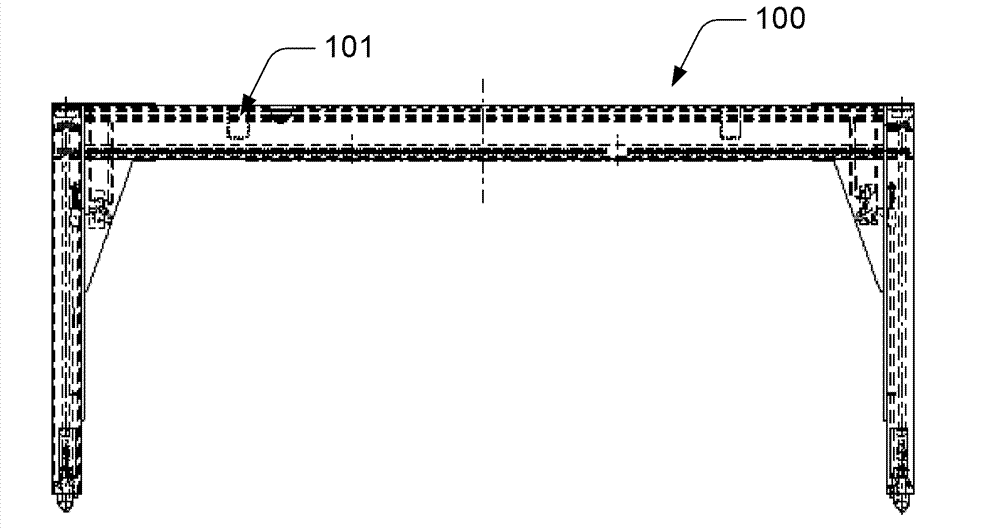

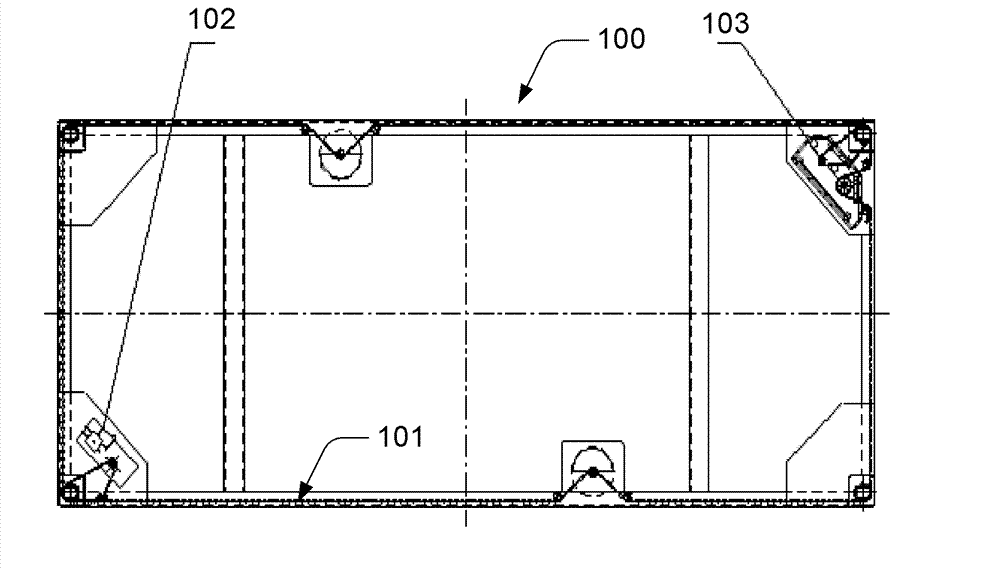

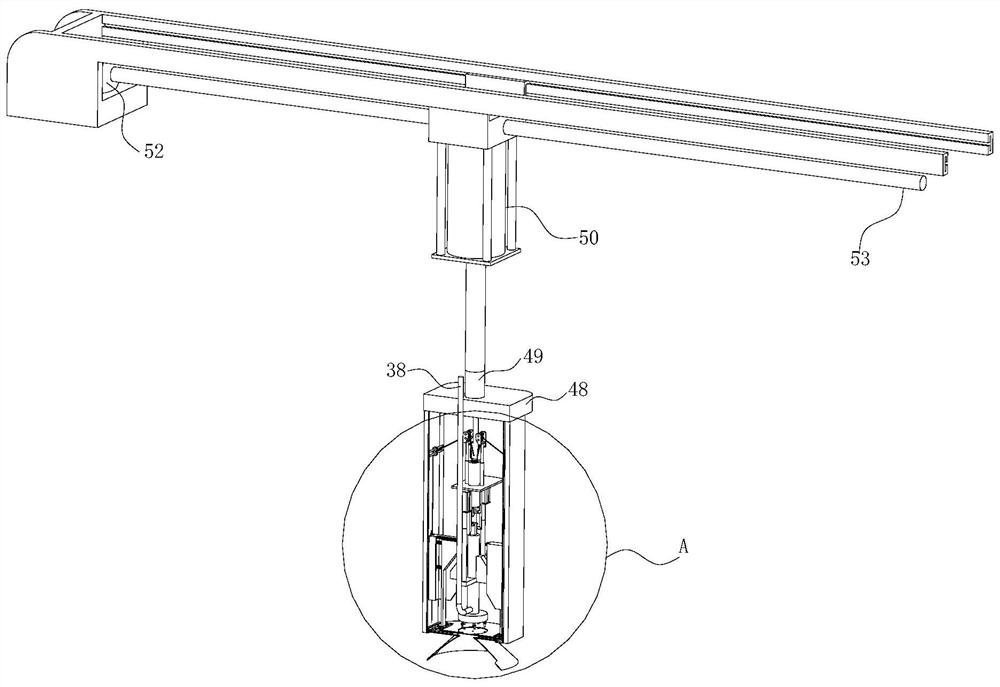

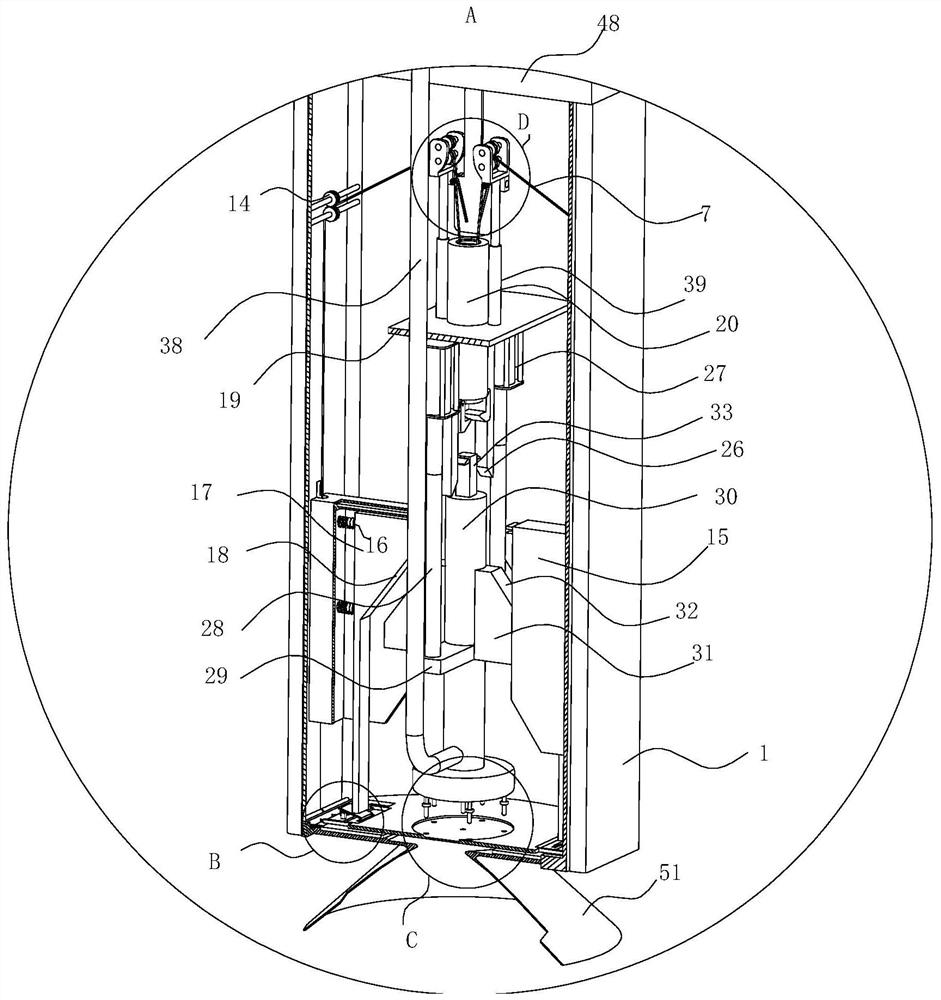

Hook-free ratchet suspension bracket

The invention provides a hook-free ratchet suspension bracket. The suspension bracket comprises a suspension bracket body having a rectangular bracket beam, a hydraulic driving mechanism arranged at one edge corner of the bracket beam, and a ratchet transmission mechanism arranged at another edge corner mutually opposite to the above edge corner and arranged on the bracket beam, wherein the hydraulic driving mechanism and the ratchet transmission mechanism are driven by opposite-angle rotation pins of a suspender. The hook-free ratchet suspension bracket can avoid part damages and decrease the failure rate, and can be applied to all suspenders, so the use of the hook-free ratchet suspension bracket is very convenient.

Owner:SHANGHAI ZHENHUA HEAVY IND

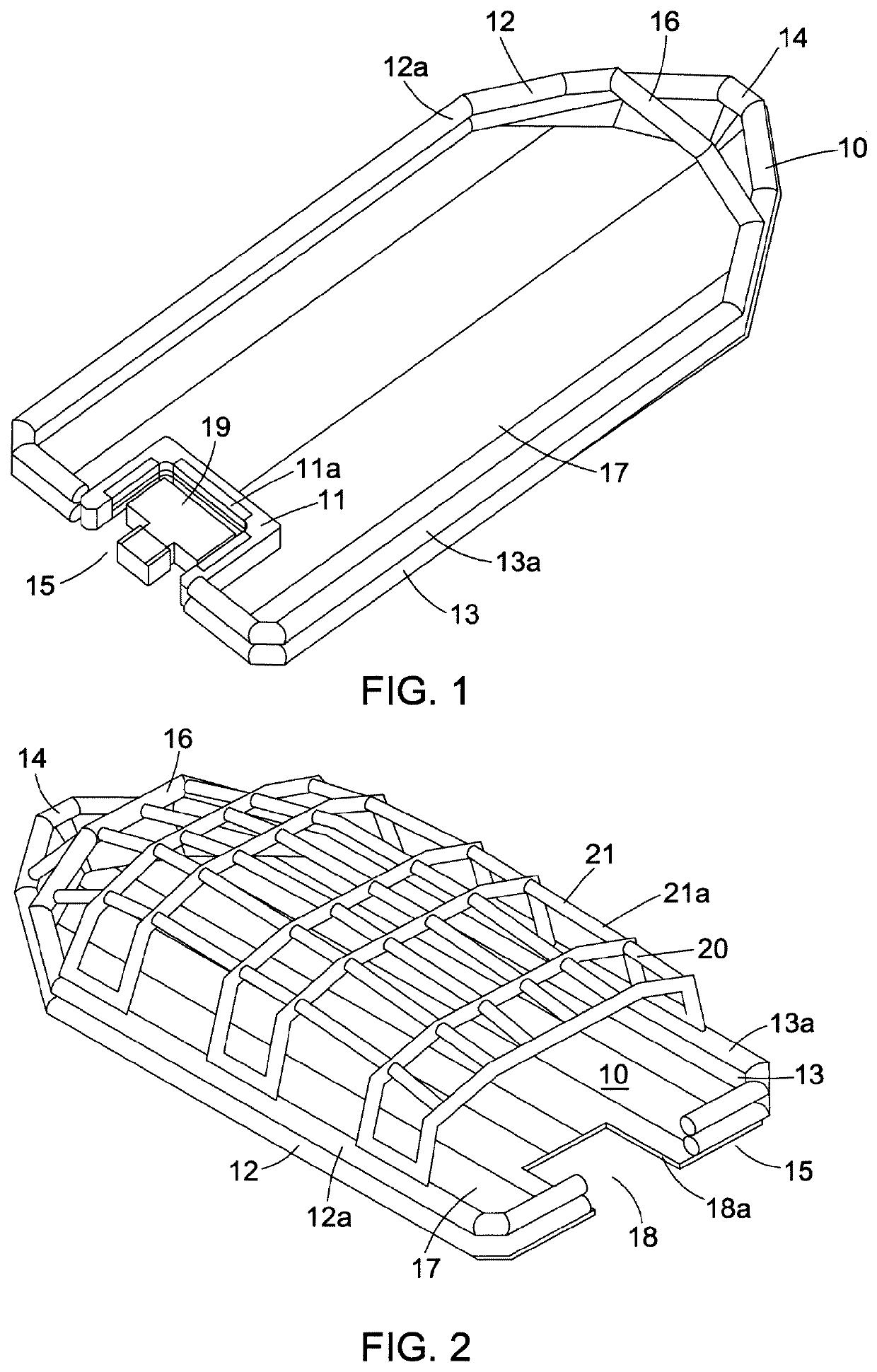

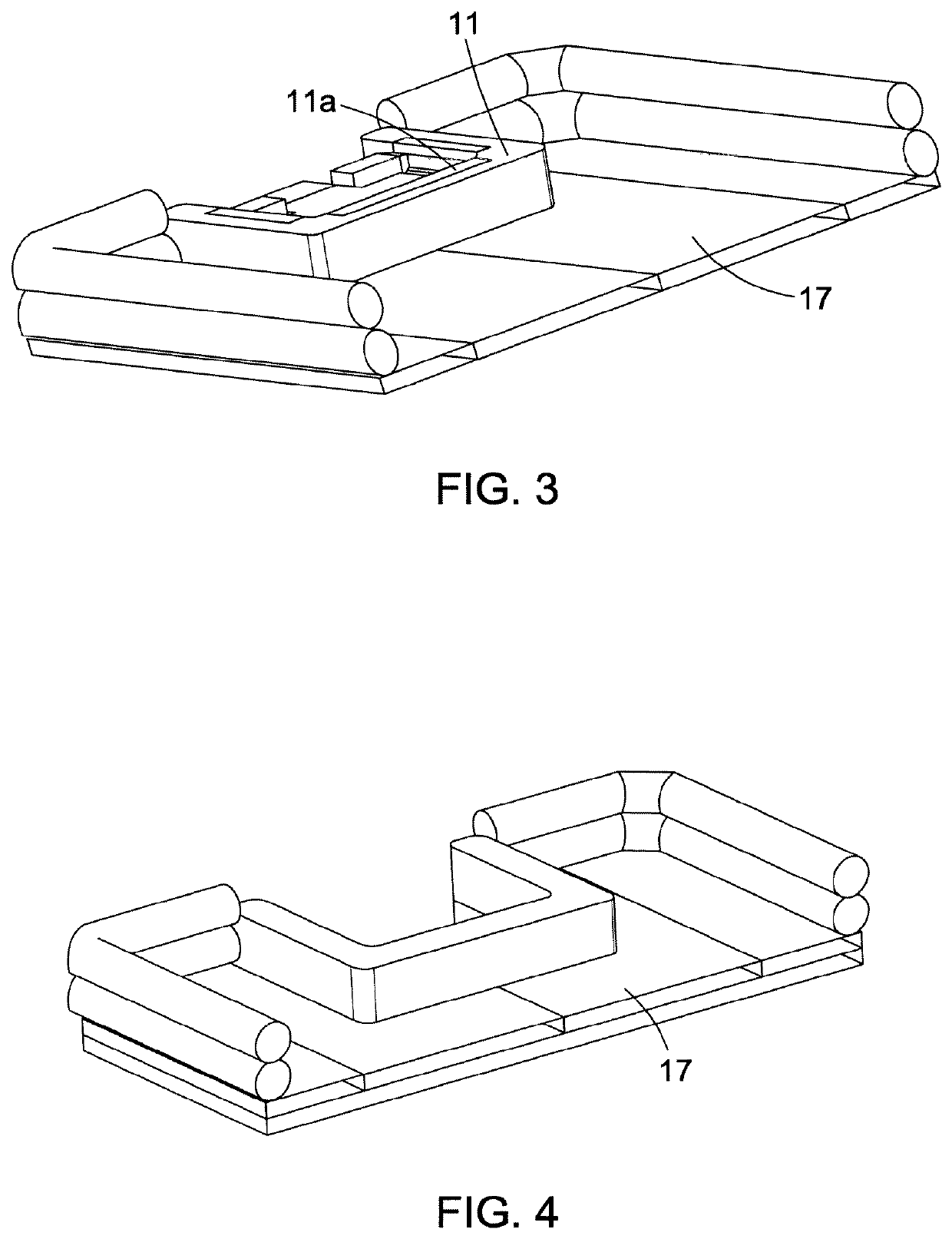

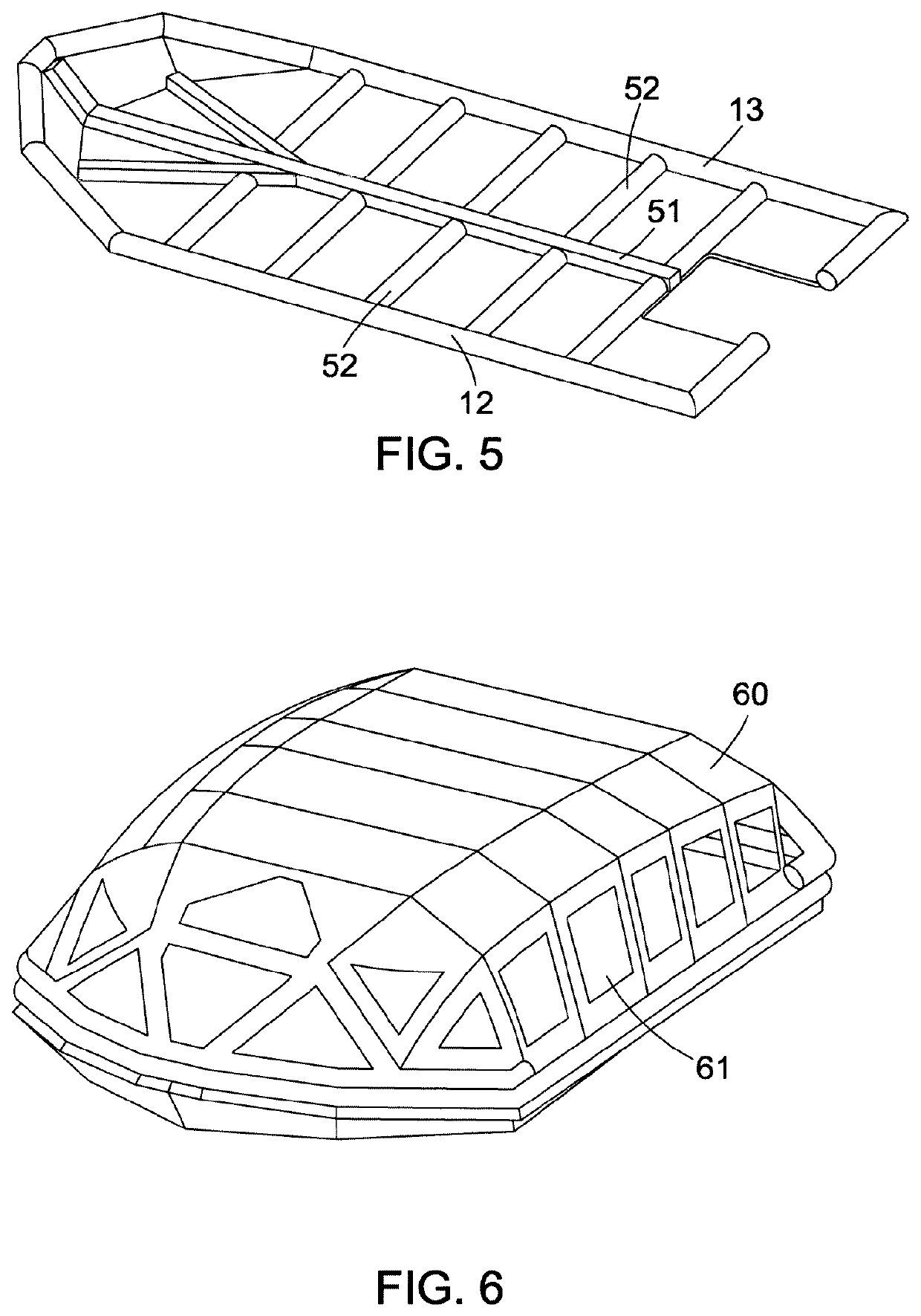

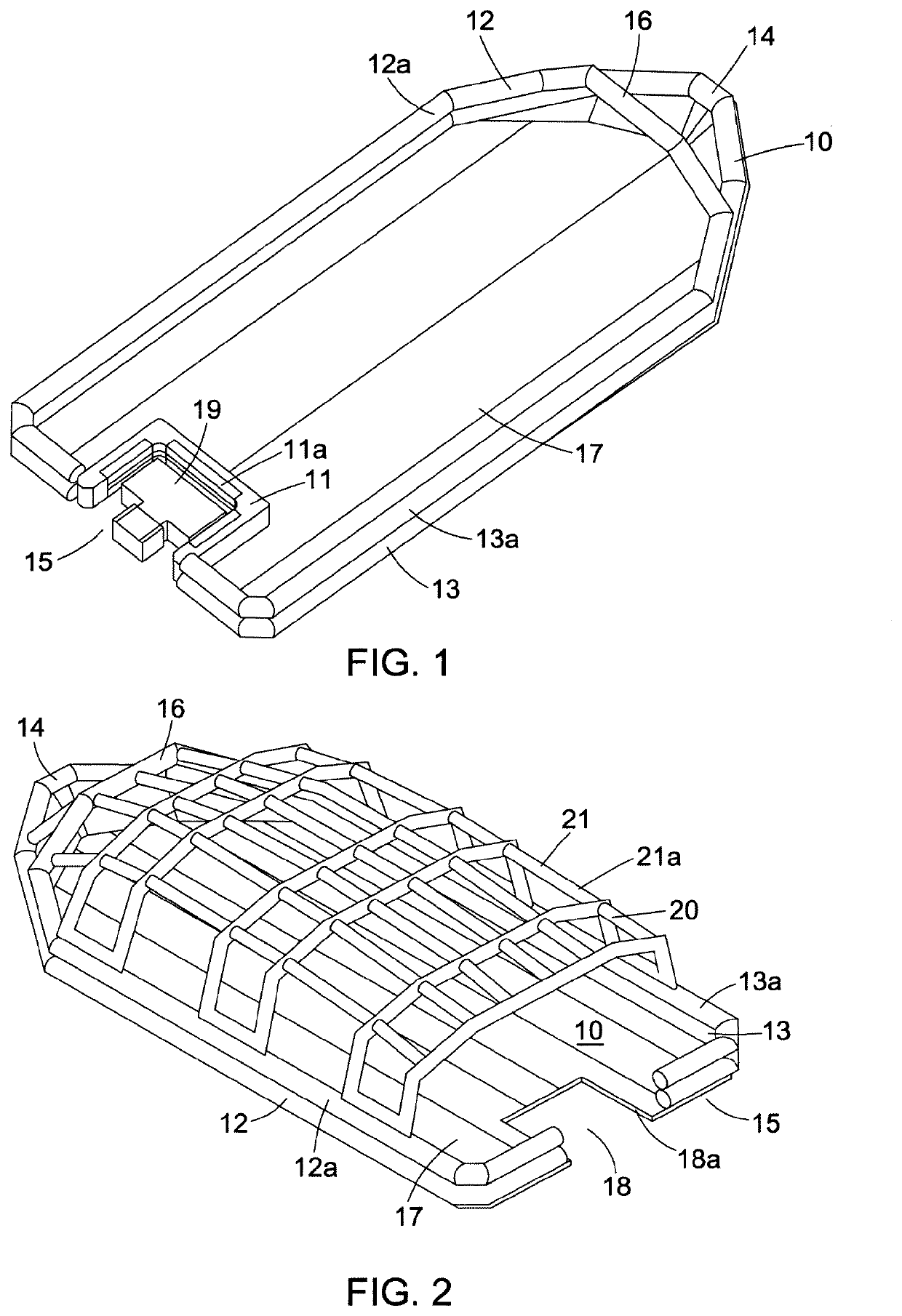

Survival craft

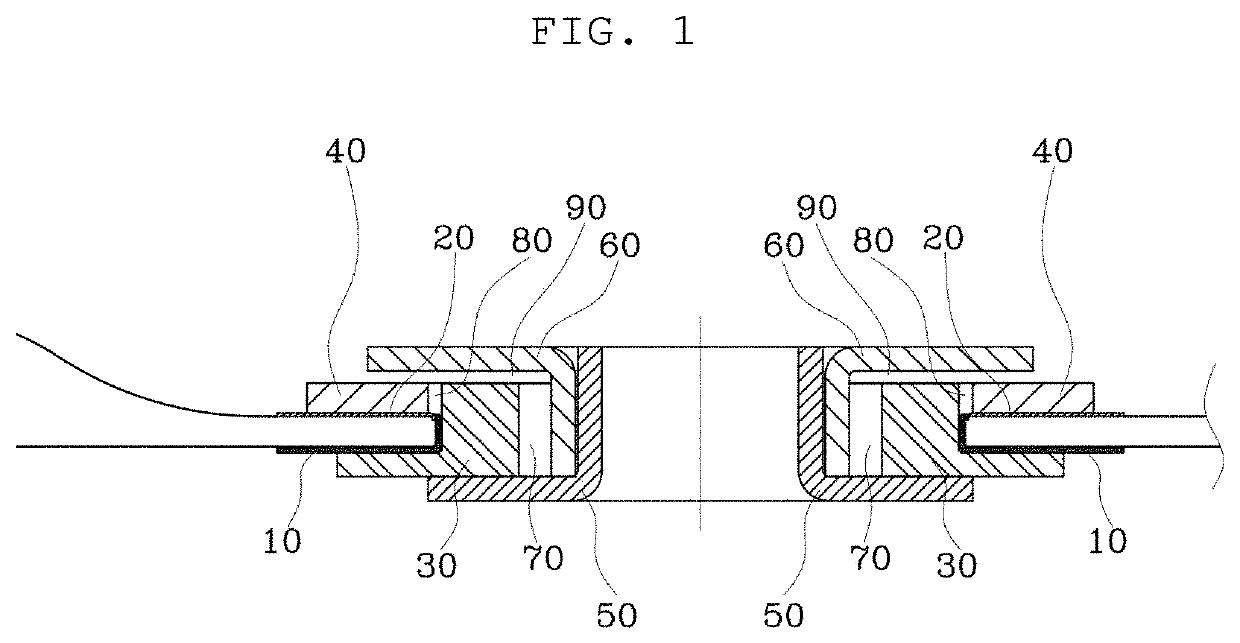

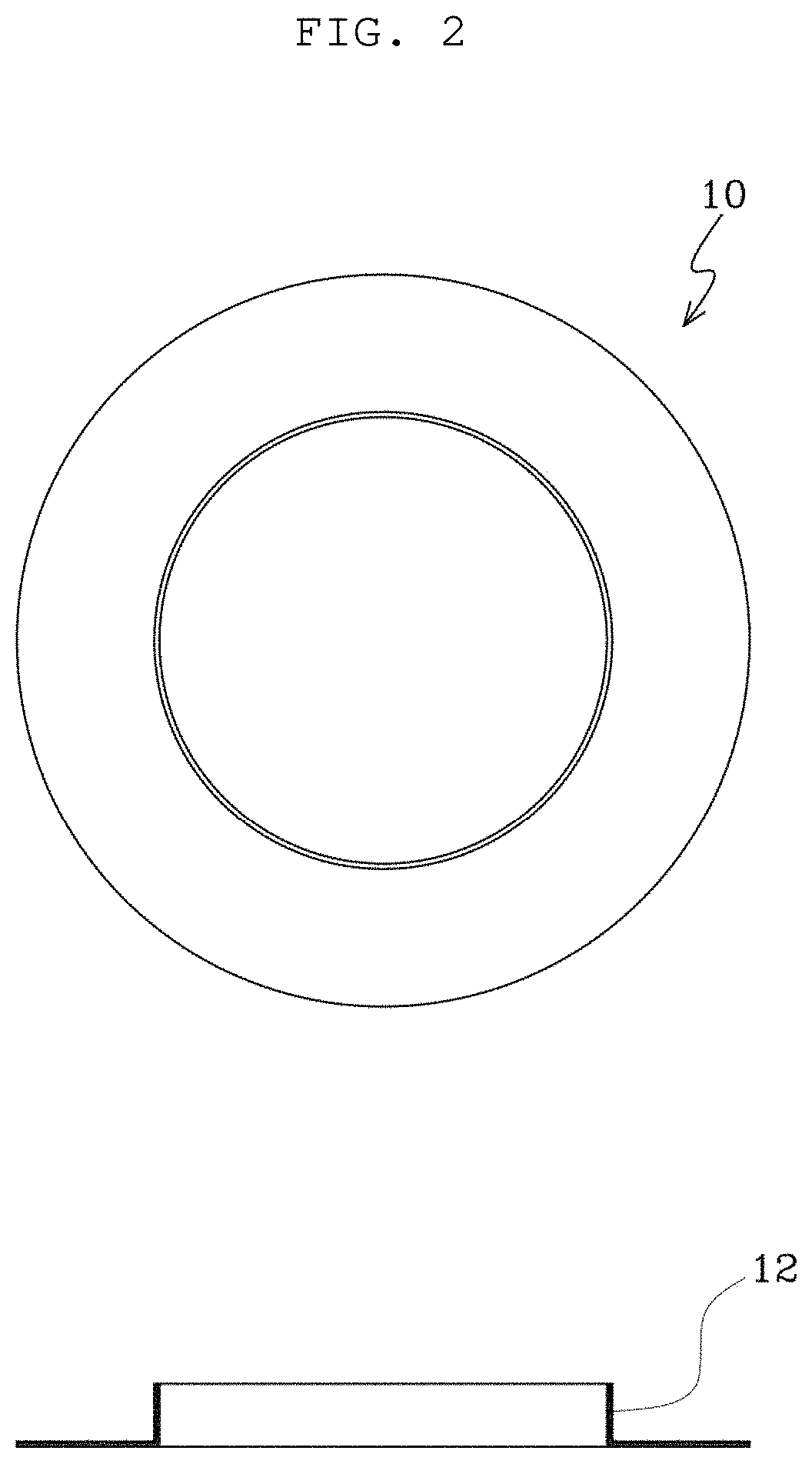

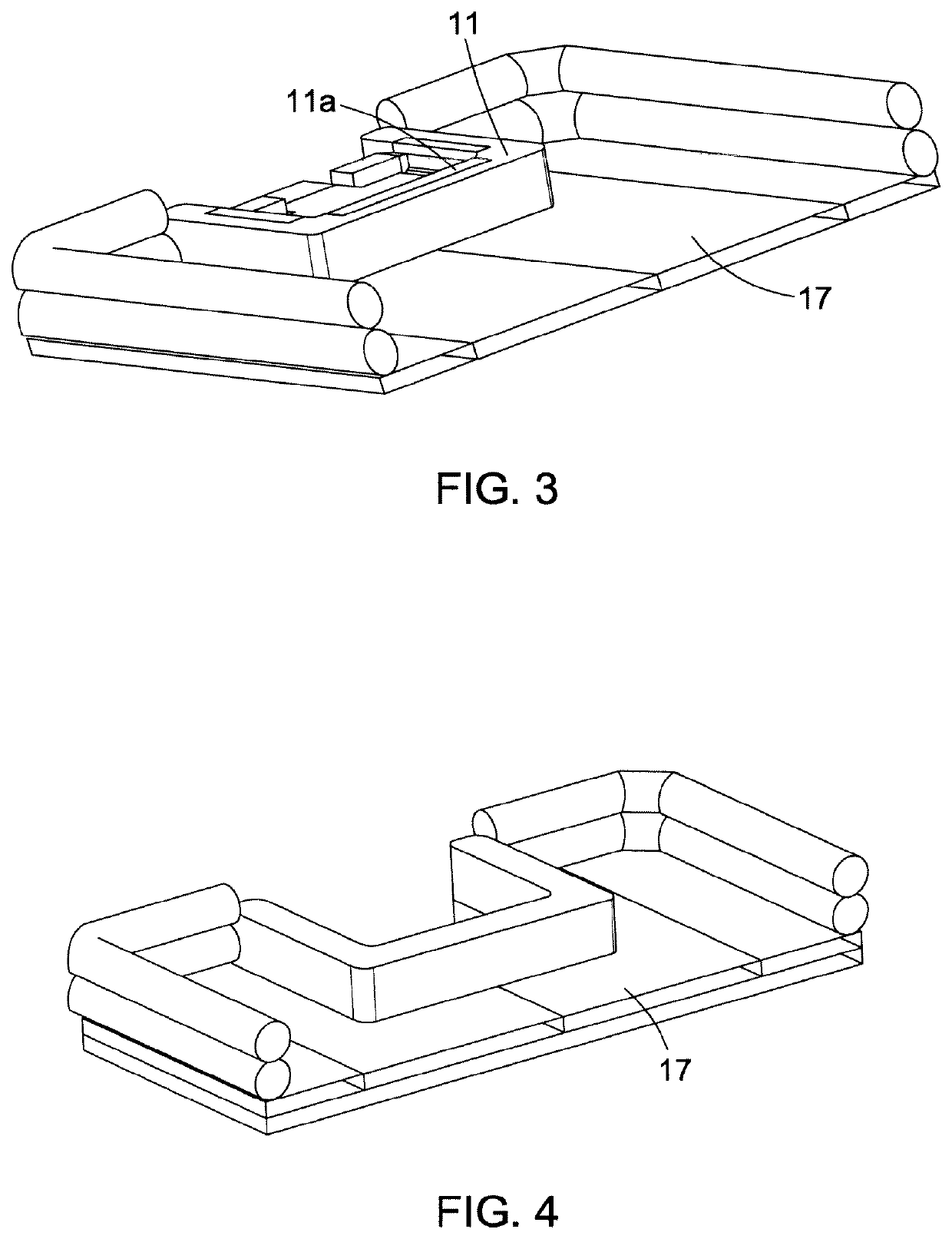

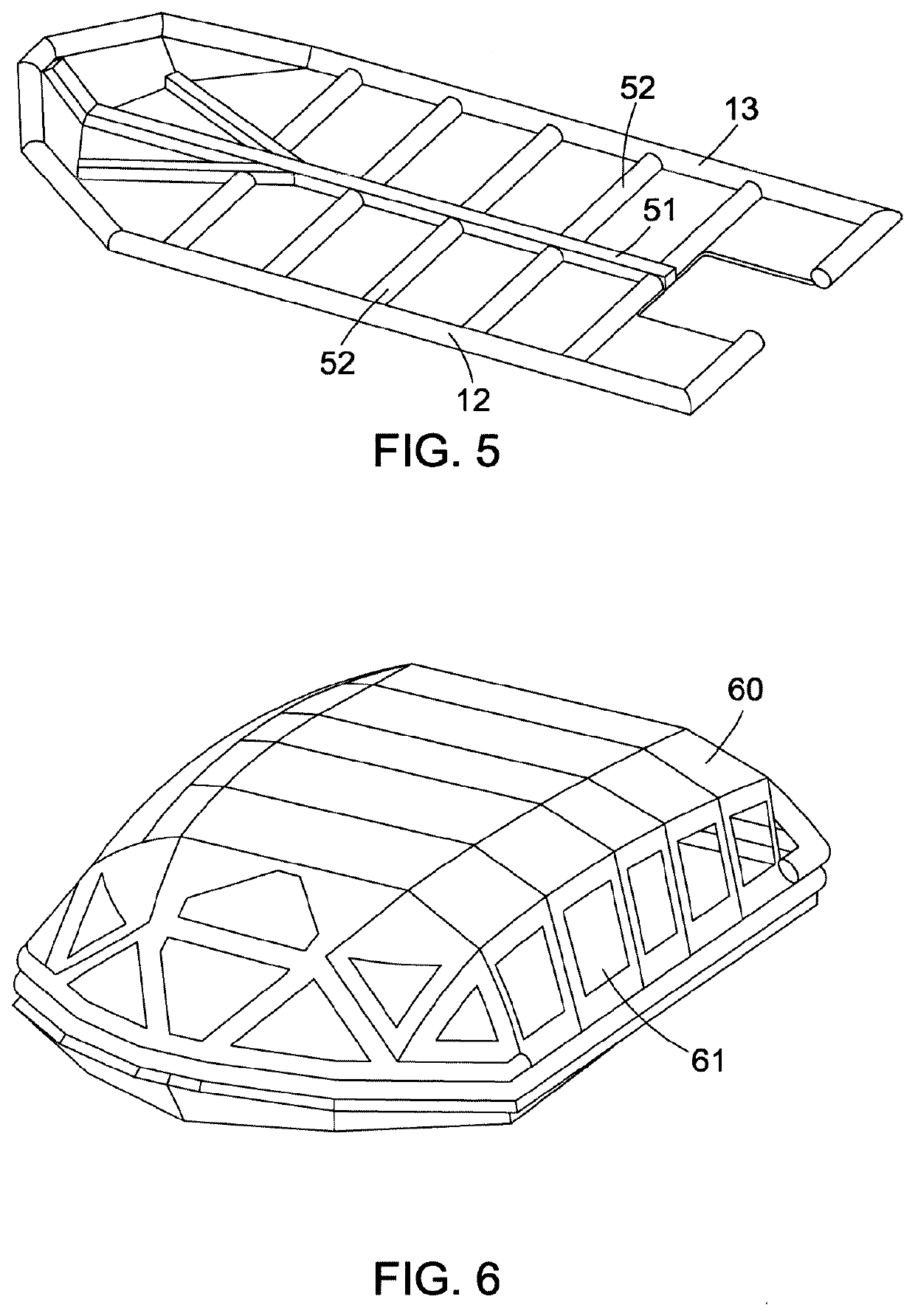

ActiveUS11167827B2Additional strength and rigidityAvoid damage to partsLife-raftsPropulsion power plantsHullIndustrial engineering

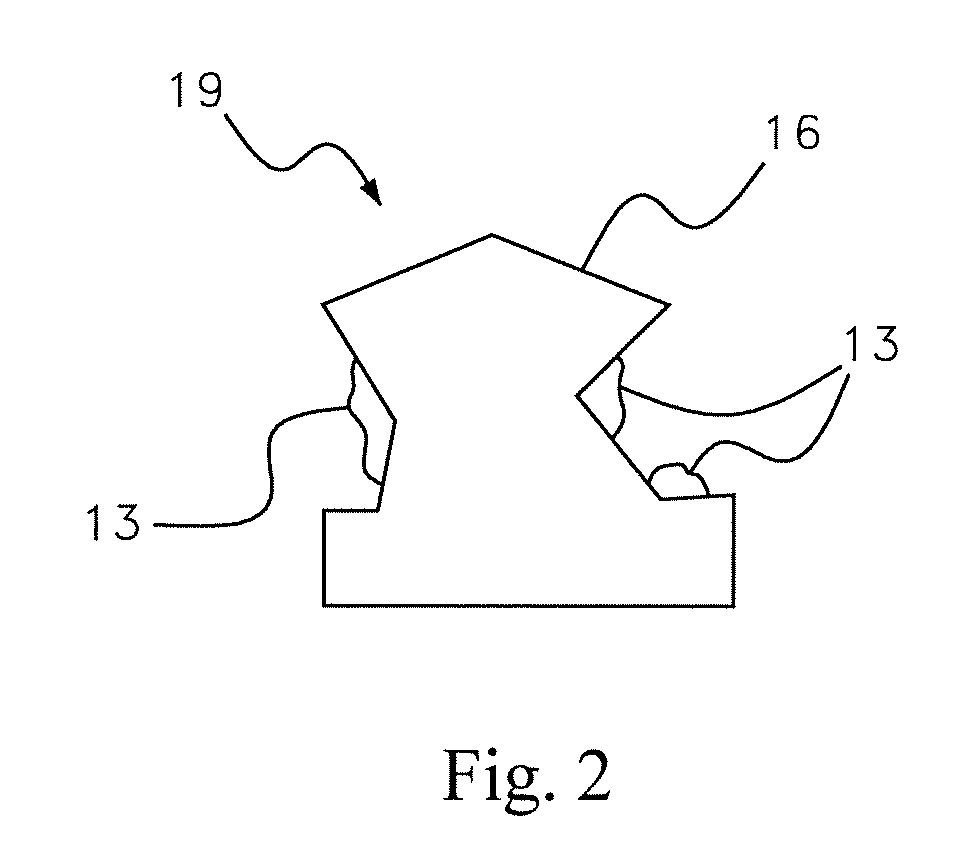

This invention relates to a survival craft comprising a hull (10) formed from inflatable members, an optional canopy support structure carried by the hull and formed from inflatable members, and an inflatable wall structure (11). The invention also relates to rigid pod (19) configured to carry a survival craft in a deflated state and be coupled to the hull when the craft is in an inflated state. The inflatable parts may be formed from drop thread material.

Owner:SURVITEC GROUP

Survival craft

ActiveUS20210214060A1Improve stabilityMethod securityLife-raftsOutboard propulsion unitsStructural engineeringMechanical engineering

This invention relates to a survival craft comprising a hull (10) formed from inflatable members, an optional canopy support structure carried by the hull and formed from inflatable members, and an inflatable wall structure (11). The invention also relates to rigid pod (19) configured to carry a survival craft in a deflated state and be coupled to the hull when the craft is in an inflated state. The inflatable parts may be formed from drop thread material.

Owner:SURVITEC GROUP

Energy-saving and environment-friendly sprinkler irrigation equipment for water conservancy projects

InactiveCN111758459AExtended service lifeAvoid cloggingClimate change adaptationWatering devicesEnvironmental engineeringMechanical engineering

The invention discloses energy-saving and environmentally-friendly sprinkler irrigation equipment for water conservancy projects, and belongs to the technical field of water conservancy project sprinkler irrigation. The energy-saving and environmentally-friendly sprinkler irrigation equipment includes a spray head frame, the top of the spray head frame is fixedly connected with a fixed platform, and a spraying mechanism is arranged inside the spray head frame. The top of the spray head frame is connected with a displacement mechanism that drives the spray head frame to move. The spraying mechanism includes a supporting plate fixedly connected to the middle position of the inner wall of the spray head frame. A supporting round table penetrates and is fixedly connected to the middle of the supporting plate. By arranging a shielding baffle, the spraying mechanism, a limiting mechanism and a traction mechanism, the protection of the sprinkler irrigation equipment after sprinkler irrigationis realized, and the problems of clogging and damaging of parts due to flying insects or other foreign objects entering the interior of the equipment when sprinkler irrigation is not needed are solved, so that the service life of the sprinkler irrigation equipment is prolonged.

Owner:合肥蓝川生态科技有限公司

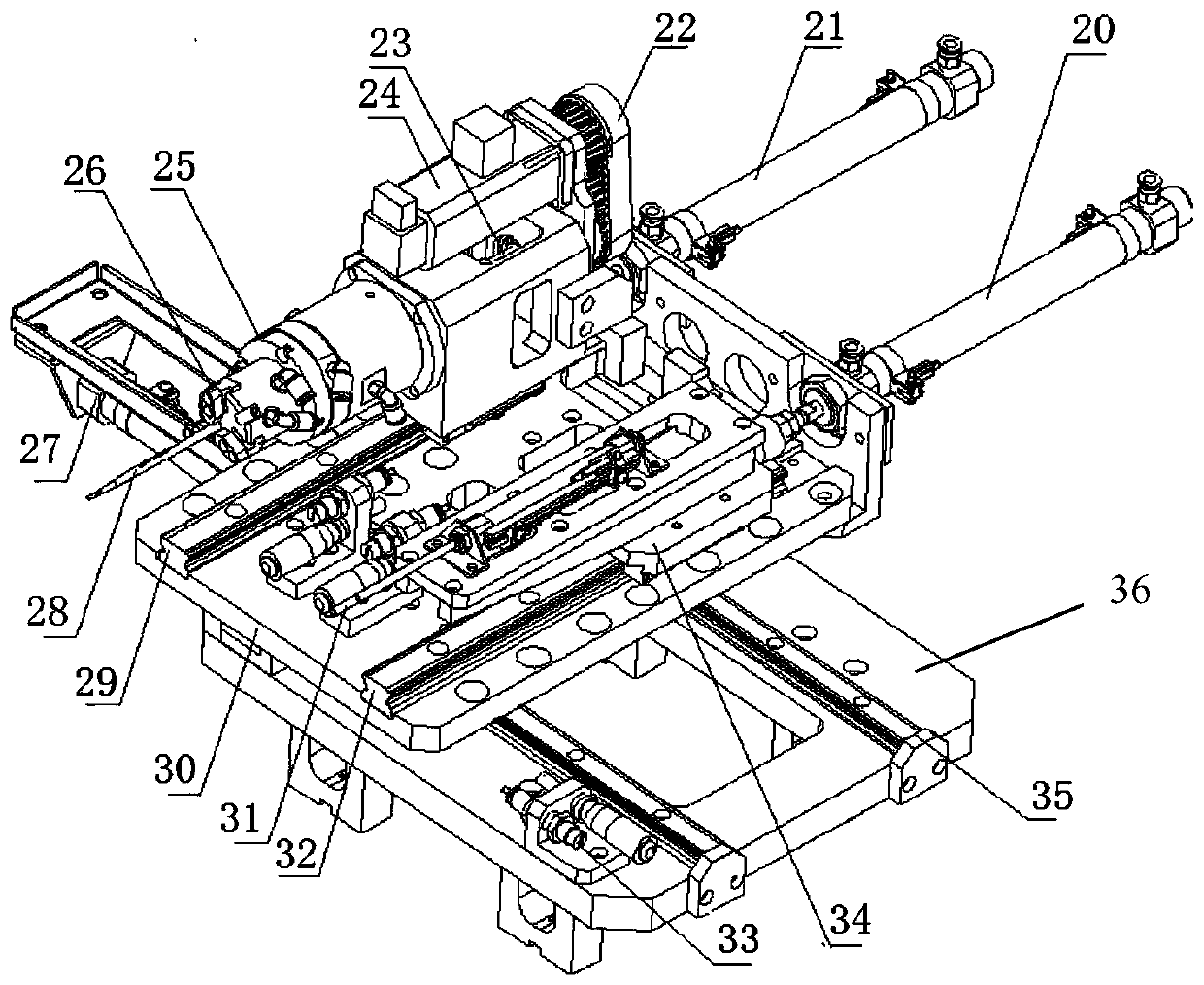

Large-batch potato quality multi-stage sorting equipment based on automation equipment

ActiveCN112871430AGuaranteed practicalityImprove the fit rangeWet separationAgricultural engineeringProcess engineering

The invention discloses large-batch potato quality multi-stage sorting equipment based on automation equipment. The large-batch potato quality multi-stage sorting equipment comprises a device bottom plate, wherein a supporting column is embedded in the top end of the device bottom plate, a material guiding assembly is detachably arranged at the top end of the supporting column, a stand column is detachably arranged at the top end of the material guiding assembly, a feeding device is detachably arranged at the other end of the stand column, an anti-blocking assembly is fixedly arranged on the surface of the material guiding assembly, a sorting box is detachably arranged at the top end of the material guiding assembly, and a feeding assembly is fixedly connected to the top end of the sorting box. According to the large-batch potato quality multi-stage sorting equipment, an arc-shaped funnel is arranged, and a plurality of small holes are formed in the surface of the arc-shaped funnel, so that when potatoes are fished out of the inner surface of a box body by the arc-shaped funnel, the arc-shaped funnel can drain water on the surfaces of the potatoes, the later processing quality of the potatoes is further guaranteed, and the economical efficiency of the equipment is further improved.

Owner:SHANGHAI KUNPENG RENDA CULTURE SPREAD

Full-automatic vacuum drying liquid injection machine

InactiveCN114597611AImprove work efficiencyImprove convenienceCell component detailsElectrical batteryControl engineering

The invention discloses a full-automatic vacuum drying liquid injection machine, the full-automatic vacuum drying liquid injection machine comprises a bottom plate, the upper surface of the bottom plate is fixedly connected with a driving box, and by arranging a second sliding rail, a first sliding block and a second air cylinder, when the device is adjusted, the second air cylinder pushes the first sliding block to move on the second sliding rail; when the dryer is driven to move, an air exhauster exhausts air for the battery through a pipeline, and a liquid box conveys liquid into a liquid injector, so that the effect of adjusting the position of the drying device is achieved, the working efficiency is improved, the convenience is improved, and a first air cylinder works to push a connecting rod to move on a first sliding rail; the relative error of liquid injection is less than or equal to 1%, the qualified rate of one-time liquid injection is greater than 99%, and the liquid injection amount is less than or equal to five hundred milliliters.

Owner:深圳市中鑫智慧科技服务有限公司

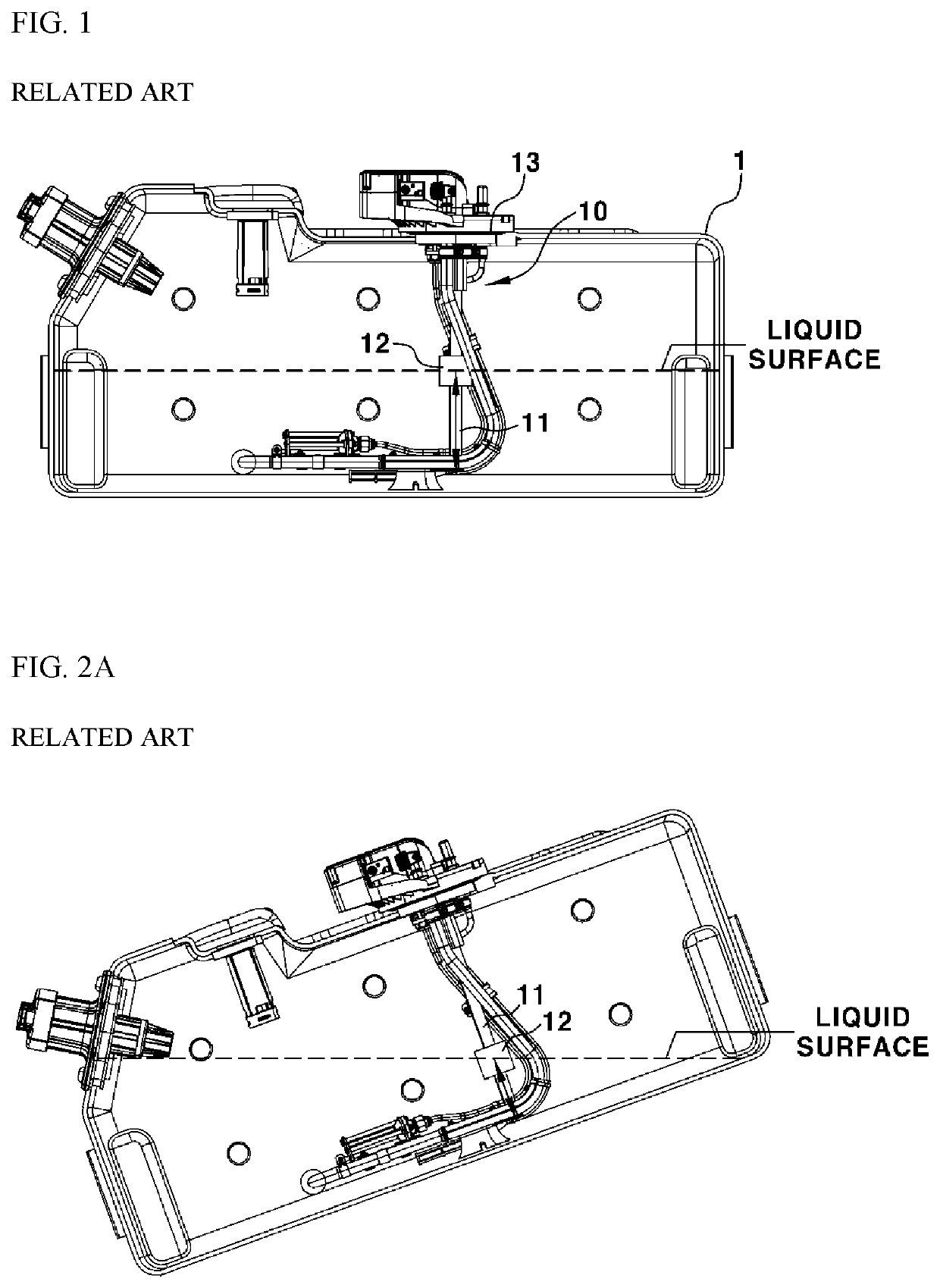

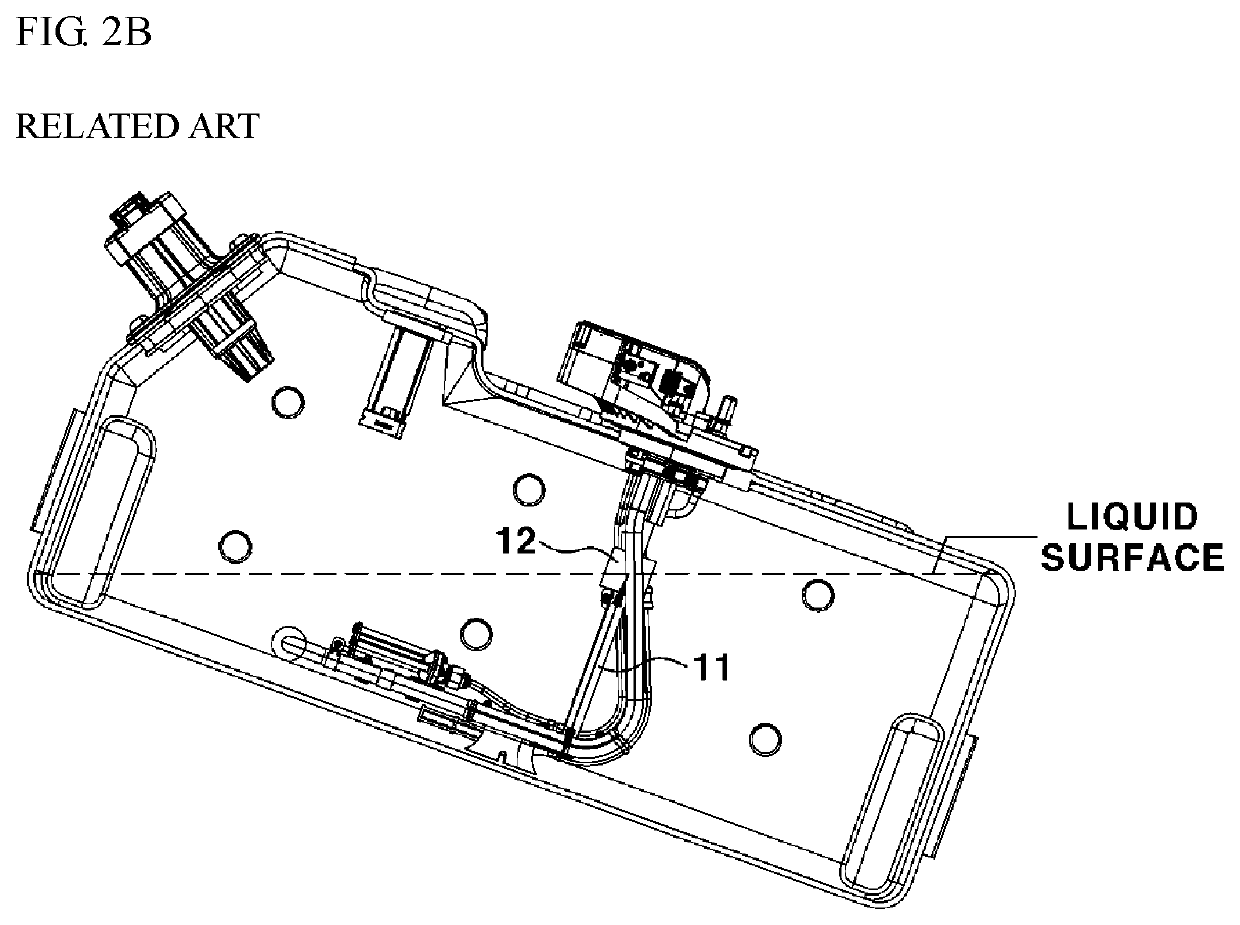

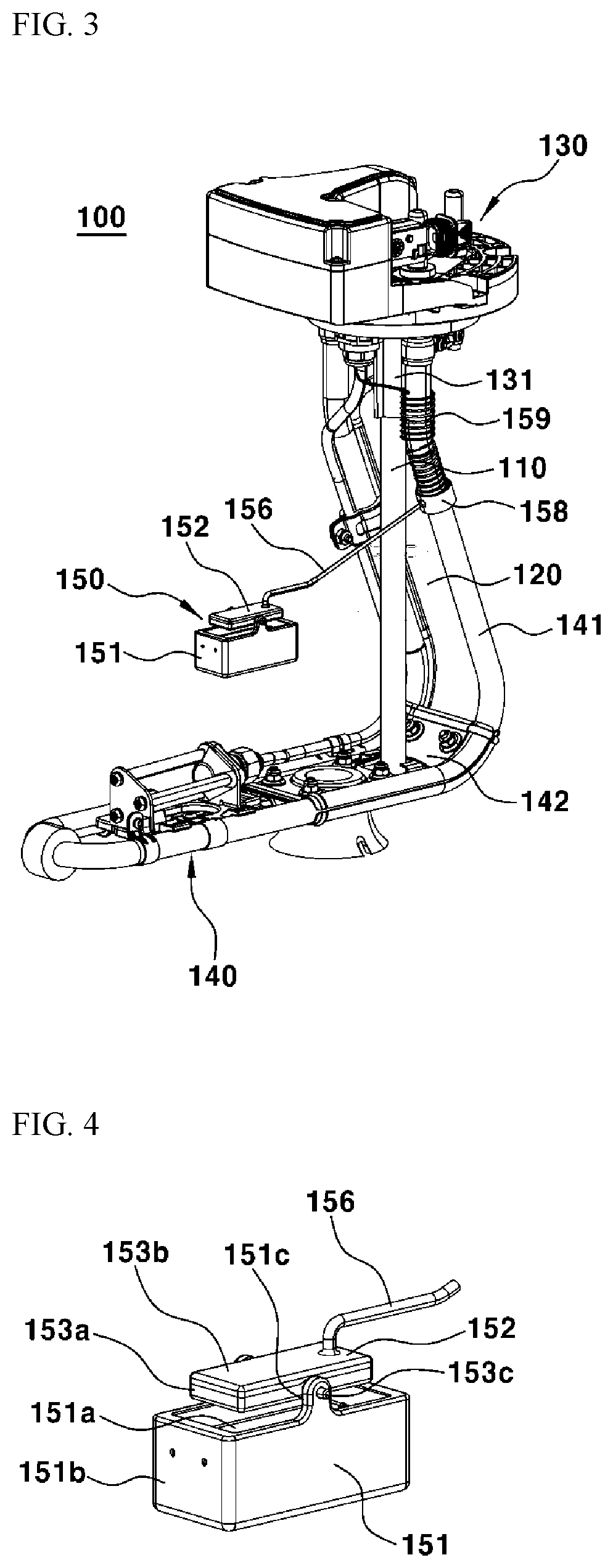

Liquid level detecting apparatus of tank for vehicle

ActiveUS20210107351A1Accurate detectionImprove efficiencyInternal combustion piston enginesExhaust apparatusControl engineeringControl theory

A liquid level detecting apparatus of a tank for a vehicle is provided. The apparatus includes a main detecting part that detects the liquid level of the liquid in a tank to output a liquid level detection signal corresponding to the liquid level and an auxiliary floater assembly that has an auxiliary floater provided to float on the liquid surface of the liquid in the tank. A gyro sensor is mounted to the auxiliary floater, and an angle detection signal corresponding to an inclined angle of the tank is output by the gyro sensor. A controller determines a final liquid level value by correcting a liquid level value obtained from the liquid level detection signal based on the angle detection signal.

Owner:HYUNDAI MOTOR CO LTD +1

A kind of superplastic forming diffusion connection integrated forming die and method for parts with reinforcing ribs

The invention discloses a superplastic forming diffusion connection integral forming mold and method for parts with reinforcing ribs. According to the part size, the size of a part blank is calculated, the blank is circled to be welded to form a cylindrical blank, a cylinder obtained after mold insert, reinforcing and seal operation finishing is put into a mold cavity, a seal ring is arranged on the mold, after mold assembly, heating is carried out, after the superplastic process is finished, the reinforcing ribs and the cylinder are completely attached to be subject to the diffusion connection process, cooling and mold stripping are carried out, and the cylindrical part with the reinforcing ribs is obtained. By means of the superplastic forming / diffusion connection integral forming technology, the titanium alloy cylindrical part with the reinforcing ribs is formed, the problem that cooling forming of titanium and a titanium alloy is difficult is solved, and it is ensured that the formed part is free of springback, the appearance is accurate and the machining allowance is small; the material utilization rate is improved, the weight of part components is effectively reduced, the working procedure and the cost of assembling connection are reduced, the mold cavity and a part inner cavity are independently sealed, the working procedure needed by the part is further reduced, the cost is reduced, and the time benefits of part machining are improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Highly Wear-Resistant Plant Genetic Lubricant Oil Additive, Preparation Method and Application Thereof

A highly wear-resistant plant genetic lubricant oil additive, a preparation method and an application thereof are disclosed. The additive includes 90-97% of a plant base oil and 3-10% of an aerogel. The plant base oil is prepared from a mixed plant oil of soybean oil, rapeseed oil, sesame oil, peanut oil, olive oil, castor seed oil, salad oil, sunflower seed oil and tung oil. The highly wear-resistant plant genetic lubricant oil additive is added to various lubricant oils for being used to devices, and a colloidal substance is generated after the devices are driven and heat is generated, so that the lubricant oils are firmly adhered to the surface of components. The lubricant oil additive not only has characteristics of high abrasion resistance, high and low temperature resistance, and oxidation resistance, but also the used lubricant oil can be regenerated and recycled after being recovered and filtered.

Owner:IDEAL NEW MATERIAL TECH HONGKONG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com