Layer for use in a hepa filter element

A filter element and filter door technology, applied in the direction of filtration separation, membrane filter, dispersed particle filtration, etc., can solve the problems that the filter can no longer meet the HEPA requirements and unfavorable filtration efficiency, so as to improve the elasticity and avoid damage to the parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

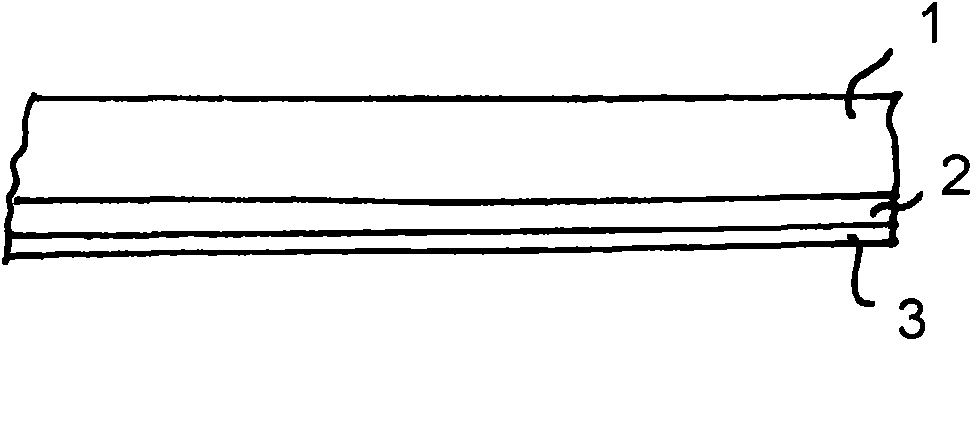

[0035] figure 1 A layer for use in a filter element is shown, comprising a first carrier layer 1 containing polypropylene fibers for stability and a second separating layer 2 containing polypropylene fibers. The polypropylene fibers of the separation layer 2 are at least partially electrostatically charged. The carrier layer 1 is likewise electrostatically chargeable and serves as a preseparator or prefilter. The carrier layer 1 and the separating layer 2 are designed as glass fiber-free nonwovens.

[0036] The carrier layer 1 has 110 g / m 2 weight per unit area, made of polypropylene fibers. The polypropylene fibers of the carrier layer 1 are designed as sheath-core fibers having an outer sheath of metallocene polypropylene and a core of pure polypropylene.

[0037] The separation layer has 36g / m 2 weight per unit area, made of polypropylene fibers. The polypropylene fibers are designed as electret microfibers. The polypropylene fibers of the separation layer 2 are appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com