Multifunctional vacuum dispensing device

A glue dispensing device and multi-functional technology, applied in the field of multi-functional vacuum glue dispensing device, can solve the problems such as difficulty in using electronic weighing equipment, and achieve the effects of preventing impact, improving sealing and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

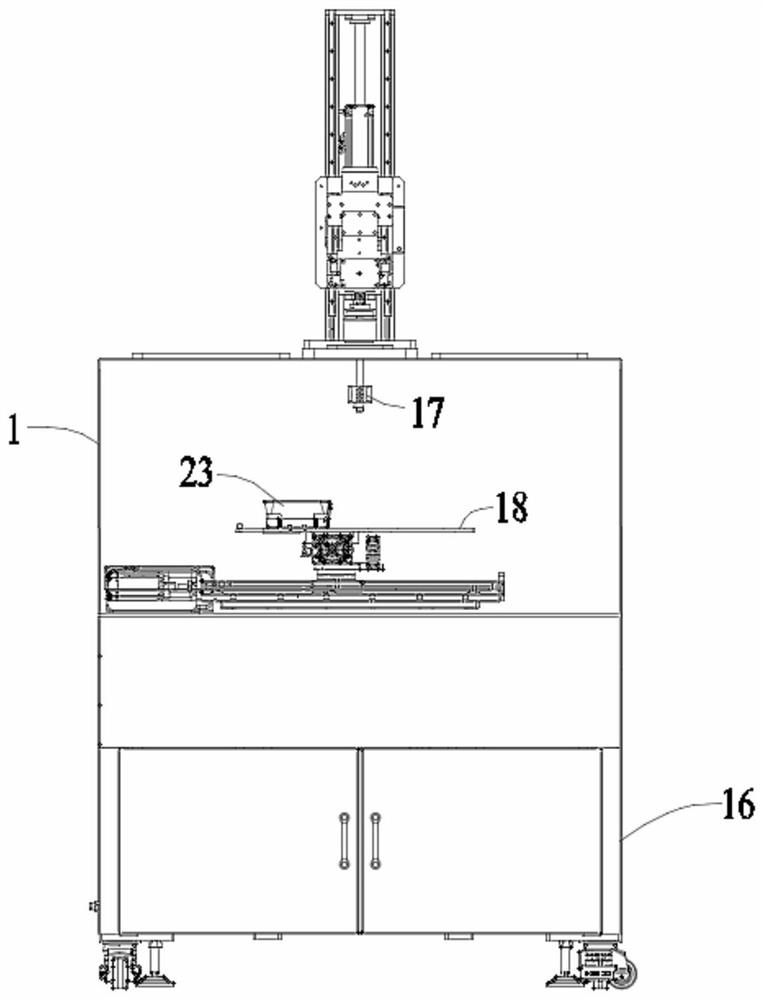

[0033] Example 1: A multifunctional vacuum dispensing device, comprising a sealing chamber 1, a frame 16, a dispensing valve 17 and a workbench 18, the sealing chamber 1 is installed on the frame 16, the dispensing valve 17 and The workbenches 18 are all located in the sealing chamber 1, and the dispensing valve 17 is located directly above the workbenches 18;

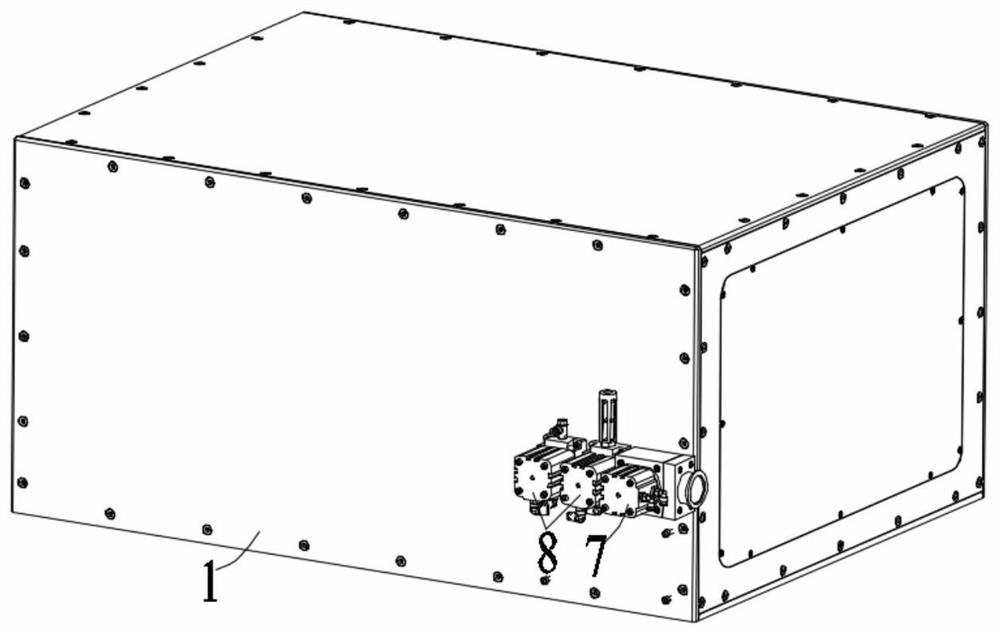

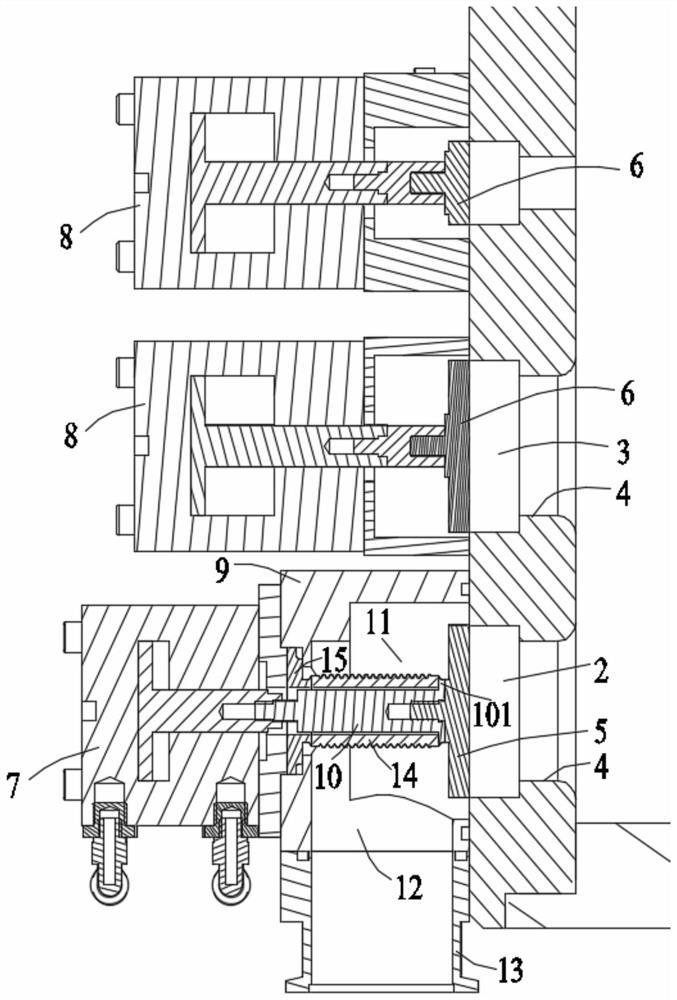

[0034] The outer surface of one side of the vacuum chamber body 1 is provided with an air outlet 2 and two air inlets 3, and the air outlet 2 and the air inlet 3 each have an inner wall near one end of the vacuum chamber body 1. The flange portion 4 protruding radially inward, a first flange 5 is embedded in the air inlet 2, a second flange 6 is embedded in the air inlet 3, and the first flange 5 is embedded in the air inlet 3. 5. The end face of each end of the second flange 6 is in contact with the end face of the corresponding flange portion 4, and the other ends of the first flange 5 and the second flange 6 are in ...

Embodiment 2

[0044] Embodiment 2: A multifunctional vacuum dispensing device, comprising a sealing chamber 1, a frame 16, a dispensing valve 17 and a workbench 18, the sealing chamber 1 is installed on the frame 16, the dispensing valve 17 and The workbenches 18 are all located in the sealing chamber 1, and the dispensing valve 17 is located directly above the workbenches 18;

[0045] The outer surface of one side of the vacuum chamber body 1 is provided with an air outlet 2 and two air inlets 3, and the air outlet 2 and the air inlet 3 each have an inner wall near one end of the vacuum chamber body 1. The flange portion 4 protruding radially inward, a first flange 5 is embedded in the air inlet 2, a second flange 6 is embedded in the air inlet 3, and the first flange 5 is embedded in the air inlet 3. 5. The end face of each end of the second flange 6 is in contact with the end face of the corresponding flange portion 4, and the other ends of the first flange 5 and the second flange 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com