Superplastic forming diffusion connection integral forming mold and method for parts with reinforcing ribs

A technology of superplastic forming and diffusion connection, which is applied to the integrated forming mold and field of superplastic forming diffusion connection of parts with reinforcing ribs, which can solve the problems of cold forming difficulties, reduce time and economic costs, and achieve the reduction of processes and supporting molds , reduce time and economic costs, and prevent impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

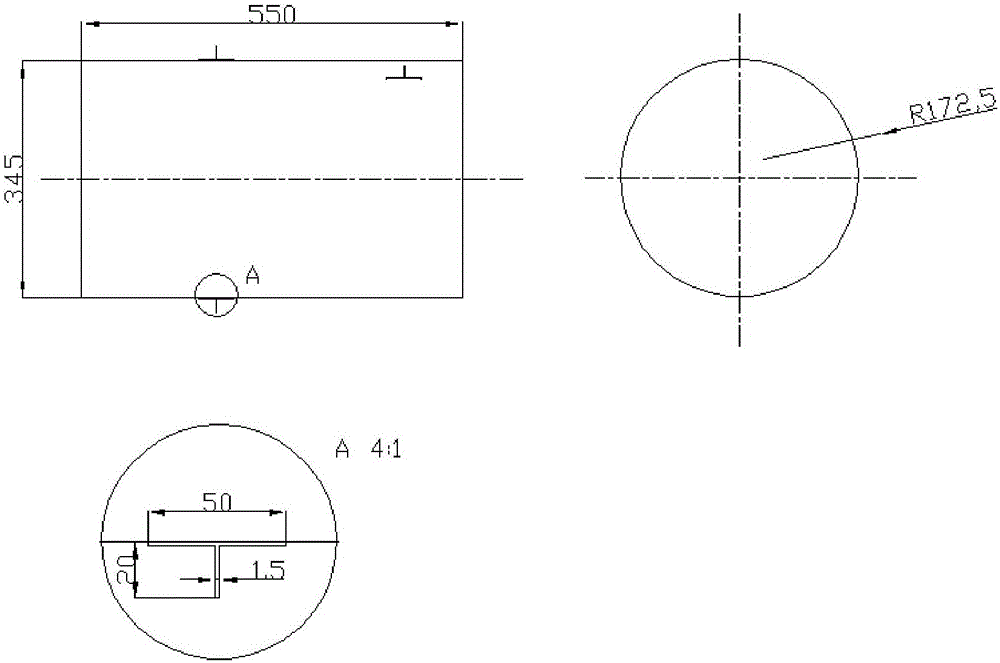

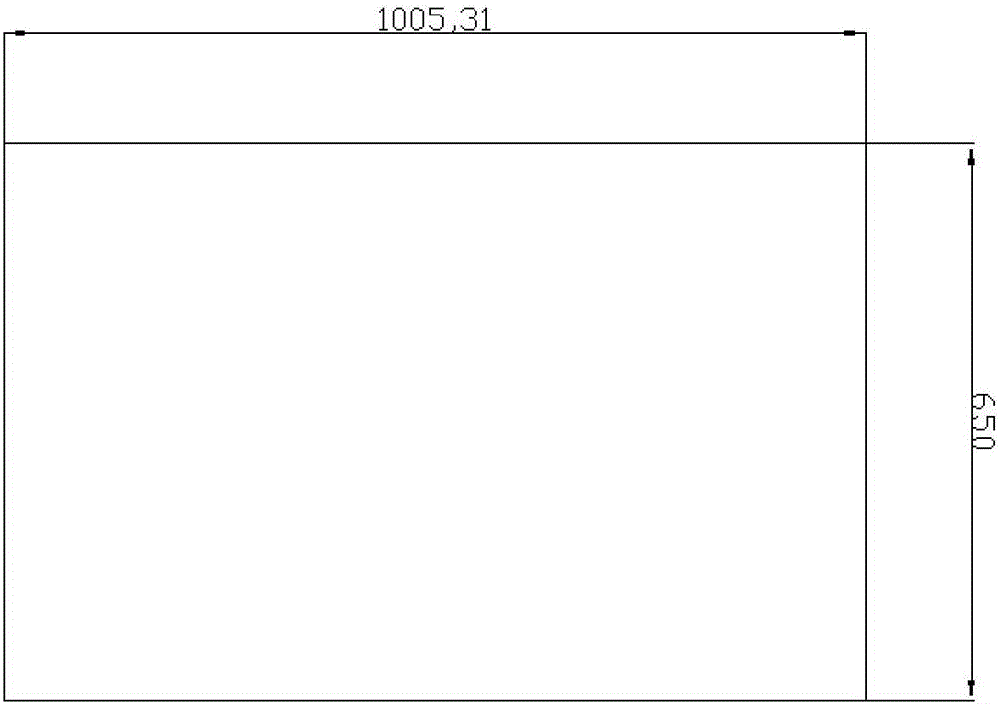

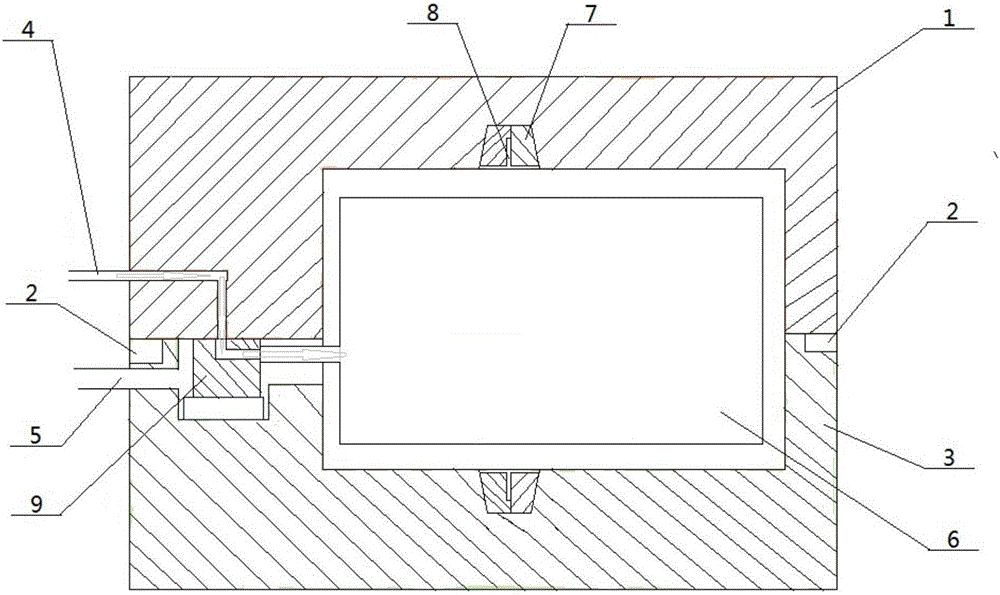

[0034] The basic idea of the present invention is to propose an integrated forming method of superplastic forming diffusion connection of parts with reinforcing ribs, which relates to a method of realizing the sealing of the cylinder cavity of the part and the mold cavity and integrally forming the cylindrical parts with ribs under high temperature conditions. The method, the method is carried out according to the following steps: a. Calculate the size of the blank of the part according to the size of the part, use laser cutting or water cutting to process the titanium alloy blank, roll the blank into a circle and weld it into a cylinder, weld the sealing cover at both ends after pickling , process a vent hole on a port cover to make a tube blank (6), and seal weld the vent hole of the tube blank (6) to one end of the transfer tube (10) (the other end of the transfer tube (10) has been welded to the titanium alloy block (9) seal welding), to ensure the smooth passage of gas; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com