Hook-free ratchet suspension bracket

A hook ratchet and ratchet-type technology, which is applied in the field of container hoisting mechanisms, can solve the problems of broken parts spreaders, inconvenient use of super-high racks, poor versatility of super-high racks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

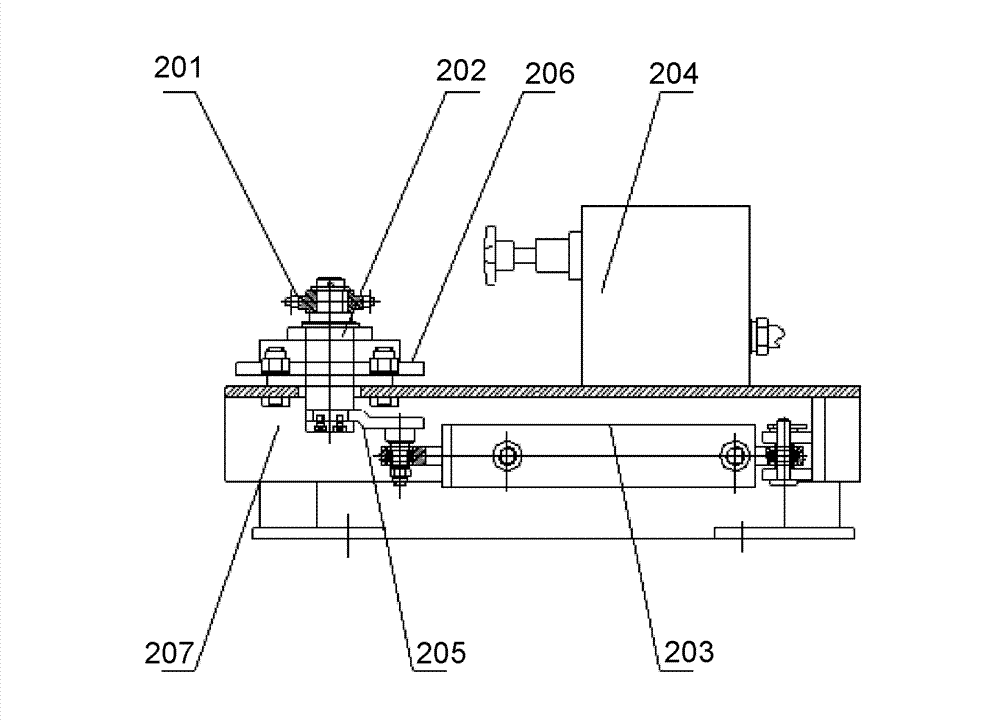

[0018] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

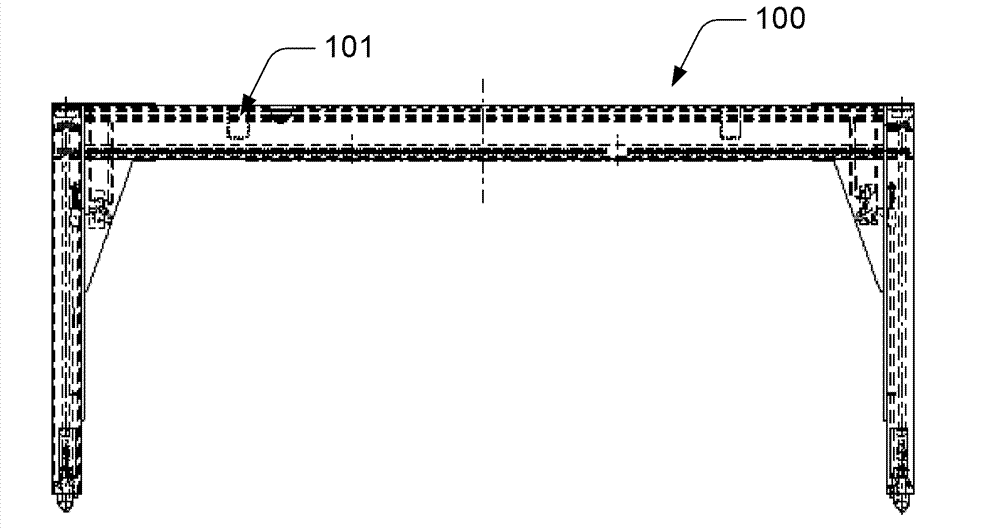

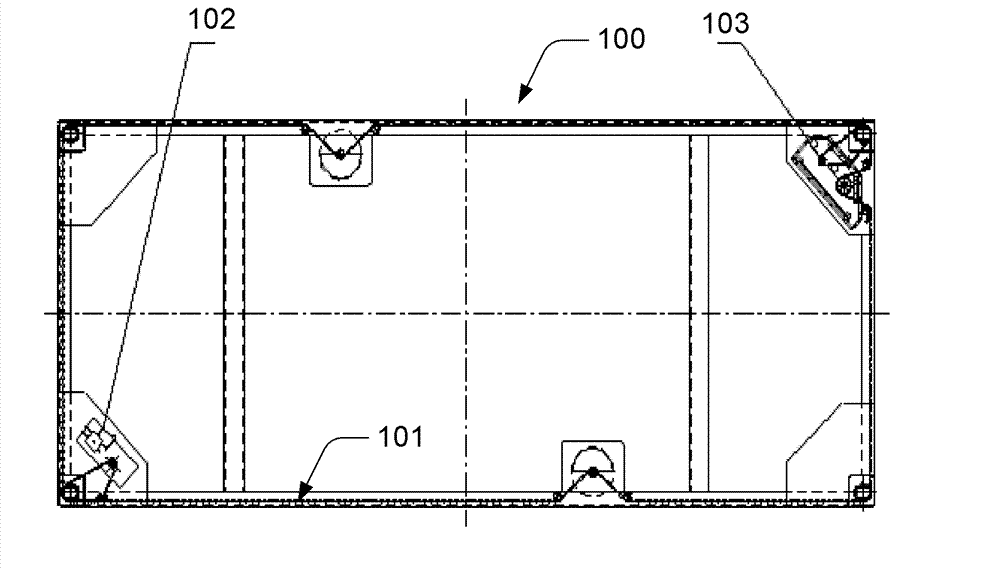

[0019] Figure 1a and Figure 1b A schematic diagram of a hookless ratchet hanger according to the present invention is schematically shown. in, Figure 1a is the main view, Figure 1b is a top view. As shown in the figure, the hookless ratchet hanger 100 of the present invention mainly includes: a hanger body 101 , a hydraulic drive mechanism 102 and a ratchet transmission mechanism 103 .

[0020] The hanger body 101 has a rectangular beam. The hydraulic driving mechanism 102 is arranged at one corner of the frame beam, and the ratchet type transmission mechanism 103 is arranged at the other corner of the frame beam which is opposite to the above-mentioned corner. That is, the hydraulic drive mechanism 102 and the ratchet transmission mechanism 103 are respectively installed in the diagonal end beams of the super high box hanger. Both the hydraulic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com