A shaft grinding process method and device for small pores

A process method and fine hole technology are applied in the direction of grinding workpiece holders, machine tools designed for grinding workpiece rotating surfaces, grinding machines, etc., which can solve problems such as damage to tool holders, grinding wheels, unstable quality, poor roughness, etc., and achieve Improve the tool rod life, not easy to collide with the knife, and improve the effect of product processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with embodiment.

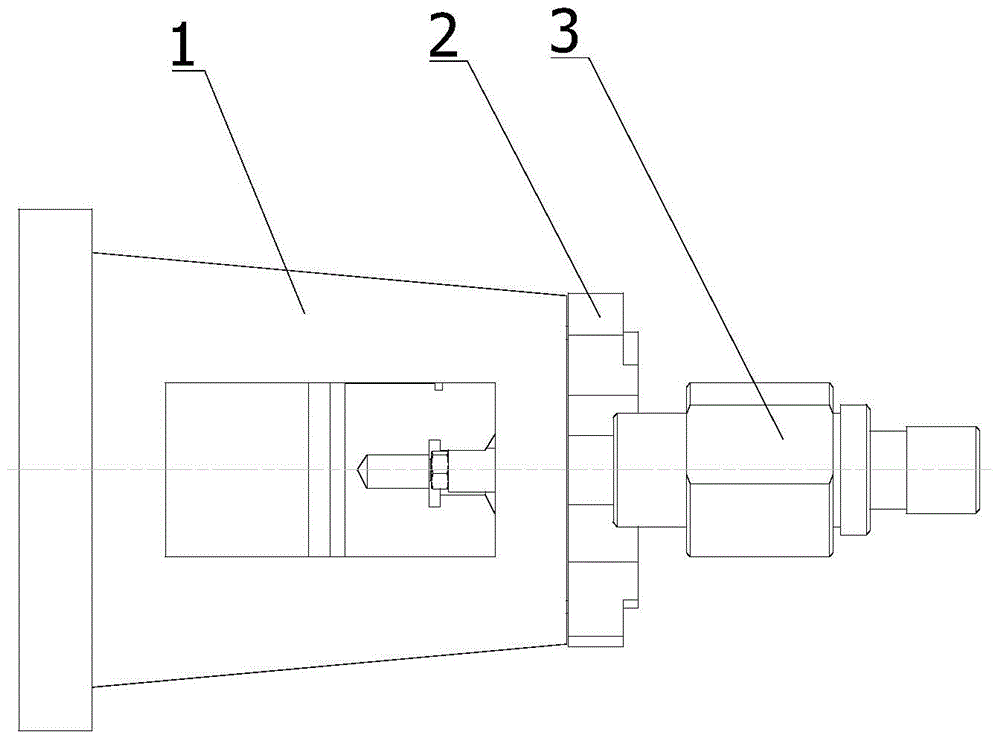

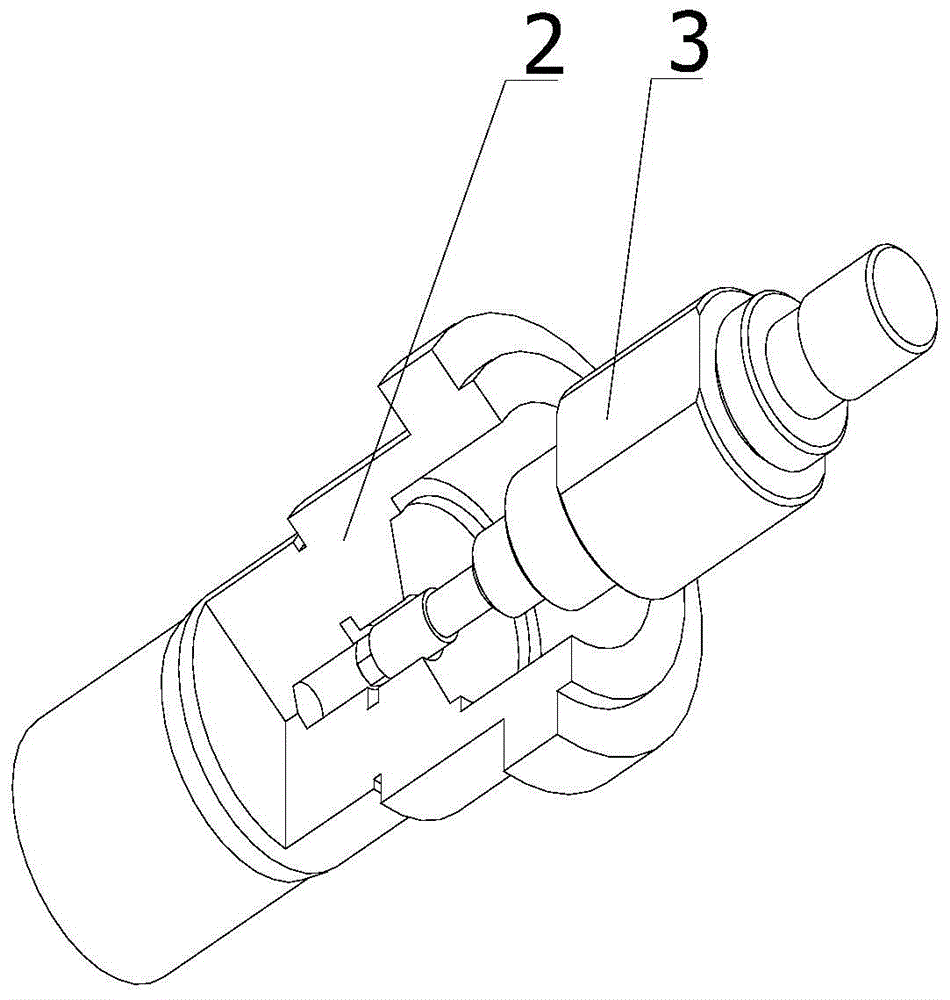

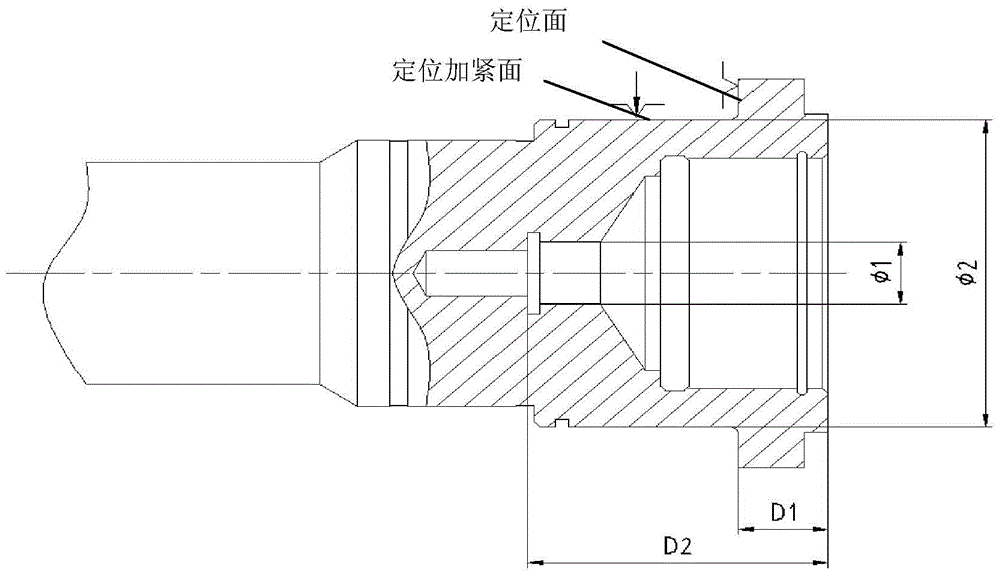

[0029] see figure 1 , figure 2 , a small hole grinding device for shafts, including a cutting fixture 1 installed on the flange of the machine tool spindle, the cutting fixture 1 is a two-stage stepped sleeve structure, and a test grinding piece is fixed inside the cutting fixture 1 2. The structure size of the test grinding part 2 is consistent with that of the shaft parts to be processed. The shape of the test grinding part 2 is a three-level stepped structure. The inside is provided with a small hole that needs to be ground. During processing, the cutter head of the tool 3 can extend into the small hole inside the test grinding piece 2. The small end of the test grinding piece 2 is cut from the small end of the cutting fixture 1. Loading, the first step surface of the test grinding piece 2 is close to the small end surface of the cutting fixture 1, the small end of the test gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com